NTE (Not-To-Exceed) Testing

Background

The US EPA introduced not-to-exceed (NTE) emission limits and testing requirements as an additional instrument to make sure that heavy-duty engine emissions are controlled over a wide range of speed and load combinations commonly experienced in use. The NTE testing requirements were first introduced as part of the 1998 Consent Decrees with heavy-duty engine manufacturers and were primarily developed with a focus on long-haul on-highway trucks. NTE testing requirements were then gradually extended on other engine categories, including mobile nonroad engines and marine engines. NTE standards and test procedures are generally referred to as “off-cycle” standards and test procedures.

NTE testing does not involve a specific driving cycle of any specific length (mileage or time). Rather, it involves driving of any type that could occur within the bounds of the NTE control area, including operation under steady-state or transient conditions and under varying ambient conditions. Emissions are averaged over a minimum time of thirty seconds and then compared to the applicable NTE emission limits. This means that engines can be evaluated for NTE compliance not only in a laboratory but also in-use.

Engine operation that falls below certain torque, power, and speed values is excluded from NTE requirements. Also excluded is engine operation that occurs in certain ambient conditions (i.e., high altitudes, high intake manifold humidity), or when aftertreatment temperatures are below 250°C. Collected data is considered a valid NTE event if it occurs within the NTE zone, lasts at least 30 s, and does not occur during any of the exclusion conditions.

Conformity with NTE standards is required during emission certification of new engines. NTE testing can also be used for in-use compliance programs. An example of the application of NTE standards and procedures is the manufacturer-run heavy-duty in-use testing (HDIUT) program where the EPA annually selects engine families to evaluate whether engines are meeting current emissions standards. Testing requires the use of portable emissions measurement systems (PEMS) to collect data from the selected vehicles over the course of a day while they are used for their normal work and operated by a regular driver. Compliance is evaluated against the NTE standards [5725].

While the NTE procedure may be suited to ensure onroad heavy-duty engines operating at highway cruise conditions meet the required emission standards, it fails to capture other operating conditions encountered by a large portion of heavy-duty diesel vehicle operation. Analysis of heavy-duty in-use vehicle test data indicates that less than 10% of a typical time-based dataset are part of valid NTE events. Also, emissions are high during many of the excluded periods of operation, such as when the aftertreatment temperature drops below the 250°C exclusion criterion. Extended time at low load and idle operation results in low aftertreatment temperatures, which in turn lead to diesel engine SCR-based emission control systems not functioning over a significant fraction of real-world operation. Test data collected as part of the EPA’s manufacturer-run in-use testing program indicate that low-load operation could account for more than 50% of the NOx emissions from a vehicle over a given workday. For this reason, the EPA replaced the NTE requirements for heavy-duty onroad engines with the moving average window (MAW) off-cycle testing procedure effective from MY 2027 [5724].

Heavy Duty Engines

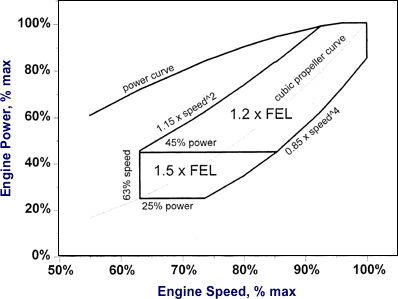

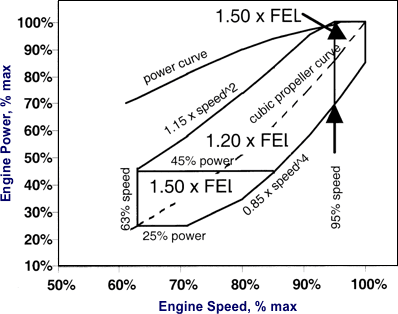

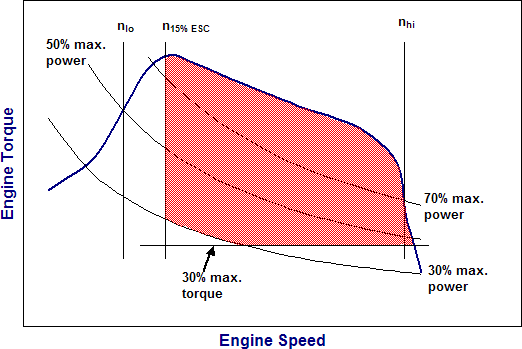

The NTE approach establishes a control area (the “NTE zone”) which represents engine speeds and loads expected to be encountered in normal vehicle operation and use by diesel heavy-duty engines. It consists of the following engine speed and load points (Figure 1):

-

All engine speeds 15% above the ESC (European Stationary Cycle) speeds:

nlo + 0.15 × (nhi - nlo)

where:

nhi = the highest engine speed on the power curve where 70% of the maximum engine power is still achievable,

nlo = the lowest engine speed on the power curve where 50% of the maximum engine power is still achievable. - All engine load points greater than or equal to 30% or more of the maximum torque value produced by the engine.

- All operating speed and load points with brake specific fuel consumption (BSFC) values within 5% of the minimum BSFC value of the engine. The manufacturer may petition to exclude any of these speed and load points where the engine is not expected to operate in normal vehicle operation. Engines equipped with drivelines with multi-speed manual transmissions or automatic transmissions with a finite number of gears are not subject to this requirement.

- All speed and load points where the power produced by the engine is less than 30% of the maximum power produced by the engine are excluded.

There are also several temperature exclusions:

- For engines equipped with exhaust gas recirculation (EGR), operation within the NTE control area is not subject to NTE emission limits during cold temperature conditions. Cold temperature operation is defined as engine operating conditions meeting either of the following two criteria (Figure 2):

-

Intake manifold temperature (IMT) less than or equal to the temperature defined by the following relationship between IMT and absolute intake manifold pressure (IMP) for the corresponding IMP:

IMP = 0.0875 × IMT – 7.75

where:

IMP = absolute intake manifold pressure in bars,

IMT = intake manifold temperature in degrees Fahrenheit. -

Engine coolant temperature (ECT) less than or equal to the temperature defined by the following relationship between ECT and absolute intake manifold pressure (IMP) for the corresponding IMP:

IMP = 0.0778 × ECT – 9.8889

where:

ECT = engine coolant temperature in degrees Fahrenheit.

-

Intake manifold temperature (IMT) less than or equal to the temperature defined by the following relationship between IMT and absolute intake manifold pressure (IMP) for the corresponding IMP:

- For engines equipped with one or more aftertreatment devices that reduce NOx or NMHC emissions, the NTE NOx and NMHC emission limits do not apply when the exhaust gas temperature measured within 12 inches of the outlet of the aftertreatment device is less the 250°C. For multi-bed systems, it is the temperature at the outlet of the device with the maximum flow rate that determines whether the NTE limits apply.

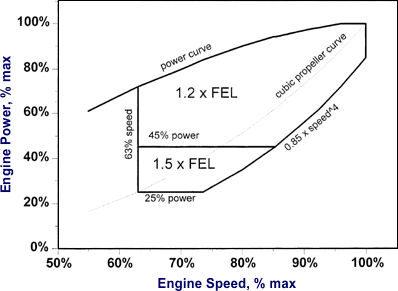

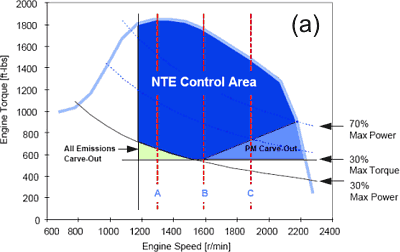

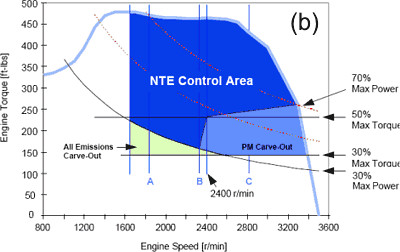

For Consent Decree engines meeting 2004 EPA standards and subject to NTE requirements, a PM carve out zone was defined at high speed and low load. PM emissions in this zone did not need to meet NTE requirements (Figure 3).

For 2007 and later model year engines, the PM carve out zone was eliminated. Instead, a manufacturer can petition the EPA to:

- have those speed and load points excluded from the NTE zone where the engine is not capable of operating and

- limit the amount of NTE testing in a single region of speed and load points if these operating conditions account for less than 5% of all in-use operation. This region should be generally elliptical or rectangular in shape and share some portion of its boundary with the outside limits of the NTE zone. Testing would not constitute more than 5% of the time-weighted operation in this region.

(a) for C less than 2400 rpm; (b) for C greater than 2400 rpm

(see ESC cycle for definition of speed A, B, and C)

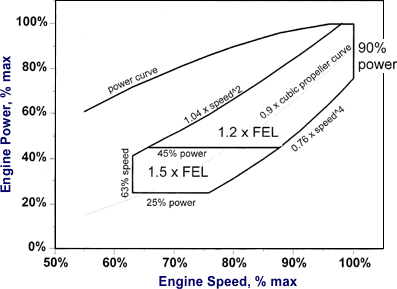

Marine Engines

The NTE zones for Category 1 and Category 2 marine diesel engines are shown in the following figures. For constant-speed propulsion engines certified using the ISO 8178 E2 duty cycle, the NTE zone is defined as any load greater than or equal to 25% of maximum power at rated speed, and any speed at which the engine operates in use.