Johnson Matthey introduces integrated SCRT® system for stationary engines

18 March 2014

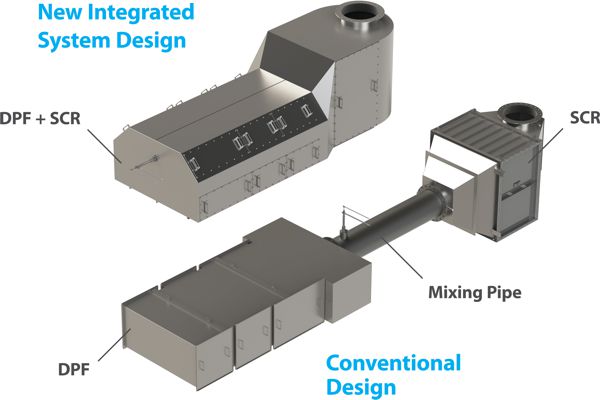

Johnson Matthey announced a new, integrated SCRT® emission control system design for stationary diesel engines. The system—which combines the CRT® diesel particulate filter and SCR technology—is intended as a retrofit solution that can reduce emission from existing engines to levels equivalent to the US EPA Tier 4 requirements.

Johnson Matthey developed the CRT technology that uses an oxidation catalyst to continuously combust the soot that is collected on the diesel particulate filter (DPF). In the new, integrated SCRT system, urea-based selective catalytic reduction (SCR) technology, the best available control technology for reducing NOx, is combined with the CRT in the same housing.

The new SCRT system, which incorporates multiple unit operations into a single package, provides a compact retrofit design capable of fitting into small spaces. The engine exhaust gas first flows through the CRT to reduce PM, CO and HC emissions. A controlled amount of urea is then injected into the exhaust before it enters the SCR catalyst modules. The urea is converted to ammonia and provides the chemical agent to reduce the NOx across the SCR catalyst.

Johnson Matthey’s Stationary Emissions Control (SEC) group supplies SCR systems and CRT DPF systems for prime and emergency diesel generators. By combining these two technologies, the SCRT system can deliver the reductions of NOx, PM, CO and HC that are required to achieve Tier 4 compliance.

Source: Johnson Matthey