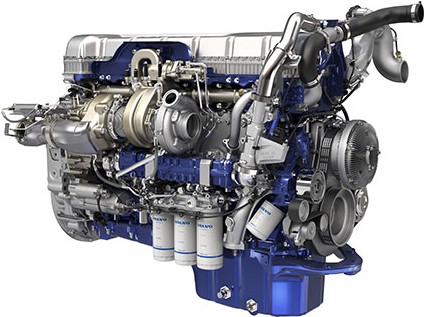

Volvo Trucks unveils new 2017 powertrains

24 March 2016

Volvo Trucks North America unveiled new integrated powertrain solutions designed for increased fuel efficiency, reliability and packaging. The new Volvo powertrains include engine enhancements, such as turbo compounding for the Volvo D13 engine; the introduction of Volvo I-Shift with Crawler Gears automated manual transmission; and a one-box exhaust aftertreatment system (EATS).

Engine Enhancements. For the first time in North America, Volvo’s 2017 D13 engine will be available with turbocompounding, a technology that recovers wasted exhaust heat and converts it to usable mechanical energy, producing up to a 6.5% improvement in fuel efficiency compared with previous engine models—said Volvo. Applications that benefit most from turbo compounding include long-haul, steady-state driving.

Volvo’s XE (eXceptional Efficiency) powertrain package with the D13 turbocompounding engine will be available to customers desiring to run in top gear in states and provinces that have 55 mph speed limits. Through downspeeding, XE allows the engine to cruise at up to 300 rpm less than the average truck sold today, further improving fuel efficiency. More than 27% of all Volvo models sold in 2015 featured an XE package.

Volvo’s 2017 11-liter D11 engine and the 2017 D13 both received updates designed to improve fuel efficiency, including a common-rail fuel system that reduces engine and cab noise, while optimizing fuel delivery; an available two-speed coolant pump that reduces parasitic loss; and redesigned pistons for greater combustion efficiency.

These improvements boost D11 to up to 425 hp, while improving fuel efficiency by up to 2.2%. The 2017 D13 will see up to a 2.5% improvement in fuel efficiency.

Volvo I-Shift with Crawler Gears. Volvo launched the I-Shift with Crawler Gears automated manual transmission (AMT). Designed with crawler functionality and startability, I-Shift with Crawler Gears is ideal for applications requiring a slow speed and maneuverability—applications such as concrete mixers with curb-pouring capability, asphalt paving, spreaders, dump trucks, heavy haul and line painters. The I-Shift with Crawler Gears also ensures startability for heavy haul and up to 220,000 lbs. GCW or more with application approval.

I-Shift with Crawler Gears will be available in two versions:

- 14 forward gears, including one low crawler gear (19.38 gear ratio) and one ultra-low crawler gear (32.04 gear ratio), which can operate down to 0.6 mph with 3.58 rear axle ratio

- 13 forward gears, including one low crawler gear (17.54 ratio).

The efficiency of I-Shift transmission can be further increased by the Volvo I-See system. I-See is a new feature which learns the topography of the road, memorizes it and stores it in the transmission for use the next time the driver travels the routes. The system stores up to 4,500 different hills.

One-Box Exhaust Aftertreatment System. Volvo introduced a new one-box exhaust aftertreatment system (EATS) that combines the diesel particulate filter (DPF) with the selective catalytic reduction (SCR) and diesel exhaust fluid doser into a single unit. The system also features a new copper-zeolite SCR catalyst that improves low temperature NOx conversion for improved emissions—said Volvo. In their first SCR engines launched in 2010, Volvo used an iron-zeolite SCR catalyst.

The new design configuration results in better thermal performance for improved efficiency, smaller packaging requirements and an approximately 17-pound weight reduction compared with the two-box unit. The new one-box EATS will be standard on the D11- and D13-equipped powertrains. The two-box solution will remain on the D16.

Source: Volvo