Conference report: 21st ETH Conference on Combustion Generated Nanoparticles

28 July 2017

The 21st ETH Conference on Combustion Generated Nanoparticles was held on June 19-22, 2017 in Zürich, Switzerland. The Conference program included a number of presentations and posters on a range of topics, including particle fundamentals, ambient air pollution and health effects, emission control from diesel and gasoline engines, particles from other combustion sources, and emission measurement. The conference also included an exhibition with the participation of suppliers of emission measurement instruments, emission control systems and related products and services.

Please log in to view the full version of this article (subscription required).

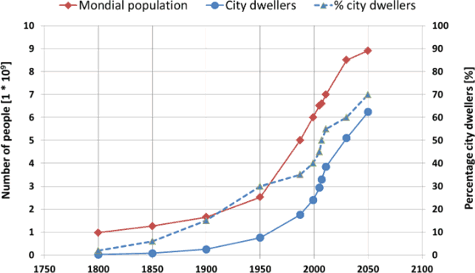

The opening Key Lecture by G. Kadijk [TNO] introduced a wider perspective on the world’s air pollution problems. In spite of the very significant progress in engine and emission control technology, air pollution—particularly urban air pollution—has been a growing problem in many areas, both in the developed and the developing parts of the world. Air pollution is related to economic activities—industrialization, infrastructure development and mobility. The fundamental reason why air pollution and other environmental problems faced by our civilization are getting worse is the explosive growth of the population and its prosperity—the world’s urban population has tripled over the last 50 years. This important realization is rarely acknowledged in the policies formulated by governments or NGOs, because it is awkward to reconcile with the principle of indefinite growth—in terms of economic growth and population growth, the latter being the main driver of the former—that is the foundation of the world’s economic and political order.

Within the status quo, the most effective way to reduce air pollution is to reduce emissions at the source—in the case of vehicles, at the tailpipe. Data from the Netherlands shows that both the PM10 and NOx pollution show generally declining trends thanks to the introduction of diesel particulate filters, EGR, SCR and other emission controls. However, real world emission risks are related to societal systems and stakeholders—including governments, manufacturers, fuel suppliers, vehicle owners and drivers. A number of such emission risks were identified. Examples include the inadequacy of the EU type approval and enforcement system (as revealed in the Dieselgate scandal), or lack of transparency in regards to emission data. The most prominent risks of technologies in daily operation include emissions lack of maintenance and tampering, for instance disabling of EGR and SCR systems or removal of particulate filters.

To address the lack of adequate test procedures for vehicles with emission control systems, a group of stakeholders—including TNO, VERT and other organizations—published a white paper on a New Periodic Technical Inspection (NPTI) procedure.

The main topics of the technical sessions related to internal combustion engines included particulate emissions from gasoline direct injection (GDI) and diesel engines and their control, diesel particulate filters, and emission measurement. The closing session of the conference was a Focus Event devoted to the future of diesel engine technology.

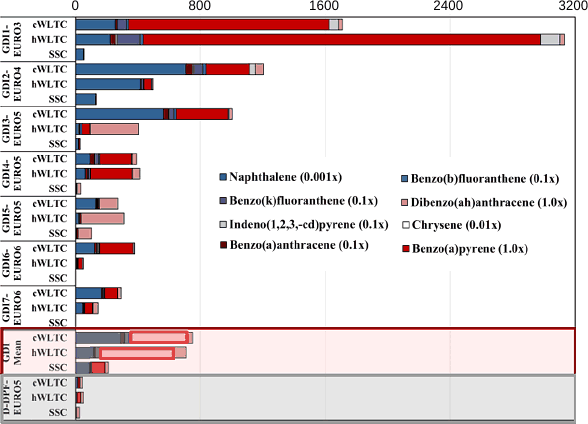

Engine Emissions. With emissions from new diesel engines controlled to very low levels, GDI engines became the suspected major source of particulate and organic semivolatile emissions. Empa [M. Munoz] reported on their ongoing investigation of the emissions of polynuclear aromatic hydrocarbons (PAH) from GDI vehicles. Seven GDI vehicles (Euro 3 - Euro 6) were tested and compared to a benchmark diesel with a DPF (Euro 5). Eight PAH species were measured, many of them genotoxic and carcinogenic. On average, the GDI engines emitted 800 more PAHs than the diesel vehicle (shown at the bottom of the chart). Even the cleanest Euro 6 GDI emitted significantly higher PAH levels than the diesel car. Four gasoline particulate filters were also tested, including two coated and two uncoated units. The GPFs reduced PAH emissions by 20-80%. The two different GPF brands that were tested showed differences in PAH conversion, while much less difference was observed between coated and uncoated units. Even with the GPF, the PAH concentrations were several times higher in the GDI vehicles than in diesel.

In another study on GDI vehicle emissions [J. Czerwiński, BFH], a 2015 Seat Leon 1.4 TSI was tested under simulated conditions of increased lube oil consumption. When 2% of lube oil was added to the fuel, PN emissions increased by about 2 orders of magnitude. The nanoparticles were eliminated by an efficient GPF, which lowered PN by 4 orders of magnitude.

Diesel Particulate Filters. CTS [A. Sappok] presented an update on the radio-frequency sensing of DPF soot and ash load. In addition to the soot load information, the technology can be now used for preventive and reactive DPF diagnostics—defined, respectively, as early detection of upstream malfunctions that could lead to subsequent filter failure, and the detection of filter failures and physical defects resulting in a reduced efficiency and soot slip.

DPF retrofit programs are considered in areas with high population of older, uncontrolled diesel engines. China’s Ministry of Environmental Protection (MEP) [Y. Wang] reported on the planned DPF retrofit program in Shenzhen—the world’s third largest container port. The Port equipment is predominantly powered by old generation diesel engines, with only 30% of the fleet meeting China II emission standards.

In Tehran, Iran, pilot retrofit DPF tests have been running since 2014 [V. Hosseini, Sharif University]. The Iranian retrofit is particularly challenging due to the poor quality of diesel fuel used in the country. New regeneration strategies tolerant of high sulfur fuels are being attempted, which combine catalysts with early post injection, EGR deactivation, increased idle, and other techniques.

In Australian coal mines, wet scrubbers have been used to control the temperature of the discharged exhaust gas below 150°C, while disposable paper-based filters downstream of the scrubber have been used for PM emission control. A new emission system has been proposed, where a platinum DOC and a ceramic wall-flow DPF are installed upstream of the wet scrubber [N. Coplin, Orbital]. The system will use a combination of thermal insulation and water cooling to ensure surface temperatures stay below 150°C, as required by coal mining safety regulations.

Focus Event: Will Diesel Technology Survive? The session was opened by Norbert Heeb [Empa], who emphasized that the diesel engine requires both an efficient particle filter and a robust NOx control technology. Compared to the three-way catalyst, the benchmark NOx control technique for gasoline engines developed by John Mooney and co-workers of (the former) Engelhard, diesel NOx reduction catalysts—including urea SCR and NOx adsorbers—still remain less reliable and efficient, especially under real driving conditions.

Other presentations in this session covered topics ranging from the effect of diesel fuel specifications on emissions [R. Williams, Concawe] and traffic related pollution abatement policies [C. Hueglin, Empa], to trends in future powertrains including battery electric and fuel cell vehicle technologies [C. Bauer, SCCER].

The next conference, 22nd ETH Conference on Combustion Generated Nanoparticles, will be held on June 18-21, 2018 at ETH Zurich, Switzerland.

Conference website: nanoparticles.ch