Conference report: 15th FAD Conference

30 November 2017

The 15th FAD Conference was held on 8-9 November 2017 in Radebeul near Dresden, Germany. The conference is organized by the Research Association for Diesel Emission Control Technologies (Forderkreis Abgasnachbehandlungstechnologien fur Dieselmotoren, FAD)—an industry/academia group to promote science and research in the field of diesel aftertreatment technologies. The scope of the conference was extended this year to include not only diesels, but all types of internal combustion engines. The meeting was attended by about 200 participants.

Please log in to view the full version of this article (subscription required).

Prof. G. Zikoridse, the Conference Chair, set the stage for the technical sessions with his opening address that summarized the unstable political climate that surrounds future mobility technologies. As governments seem unable to cope with the growing levels of air pollution in our increasingly crowded and congested cities—and on the global scale, with reducing carbon emissions—many policymakers embrace the idea of electric vehicles (EV) and propose “bans” and other discriminatory policies on combustion engines. However, electric vehicles are a technology that in many respects remains nonviable—technically and economically—and which is clearly not a silver bullet to solve the sustainability problems faced by our civilization. This is particularly clear in Germany, where nuclear power is to be phased out—a policy that will make it very challenging to decarbonize the country’s electricity mix.

Automotive Powertrains. Volkswagen [S. Schmerbeck] presented an automaker’s perspective on future drivetrains for passenger vehicles. The main driver in the development of vehicle technology is CO2 emission reduction. The maximum future potential using internal combustion engines is about 90 g CO2/km (with diesels slightly better than gasoline engines). Therefore, future drivetrains should include a mix of combustion engine and electric vehicles. Volkswagen target is to have 20-25% electric in their vehicle mix by 2025. However, the future of e-mobility is still difficult to predict, with the critical unknown factors including the battery technology and the electrical charging infrastructure. The combustion & electric vehicle technology mix must be supported by two key components: CO2-neutral electricity and CO2-neutral fuels. Promising renewable fuel technologies [T. Garbe, VW] include liquid fuels manufactured from biomass, such as the VW Sun fuel, as well as liquid fuels manufactured from CO2 using renewable electricity—sometimes referred to as electrofuels.

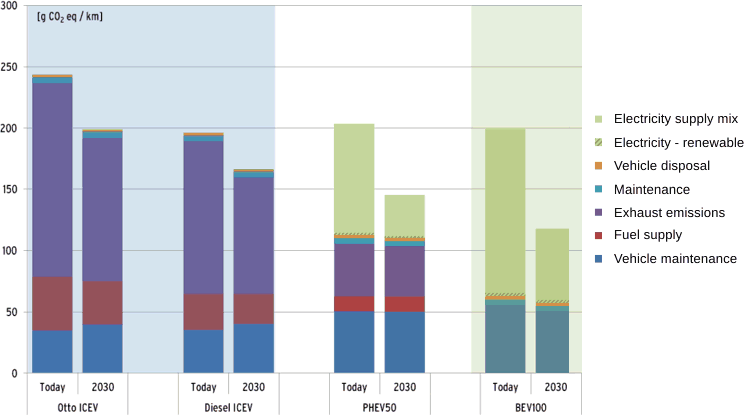

Germany’s UBA (Environment Ministry) commissioned a life cycle analysis of electric vehicles, which was conducted by the Institut für Energie- und Umweltforschung Heidelberg (ifeu). Based on German electricity mix, electric vehicles increase lifecycle CO2 emissions compared with diesels (see figure below). By 2030, the GHG impact of EVs should be reduced due to a greener energy mix.

The report identified a number of other EV risks, such as negative environmental impacts of vehicles manufacturing and increased local renewable electricity demand. Resource demand in EV manufacturing is extremely high, largely due to the battery materials. Raw materials classified as ‘critical’ in the analysis include cobalt and rare earths (both are not used in conventional vehicles), as well as chromium, magnesium, tantalum, and other metals. Demand for resources would climb in proportion to the volume of electromobility. For instance, 38% of the global annual cobalt extraction would have to be consumed to produce 10 million EVs per year.

The modern diesel engine, utilizing advanced engine technology and emission aftertreatment, has become remarkably clean [T. Koch, KIT]. Through the mass introduction of diesel particulate filters at the Euro 5b (2011/2013) stage, the problem of diesel particulate emissions and their contribution to the ambient PM10 exposures (in Germany) has been solved. NOx reduction technologies have been also developed that allow to reduce NOx emissions from diesel vehicles to very low levels. While some diesel vehicles continue to produce high NOx emissions in real driving—contributing to ambient NO2 inventories and exposures—the diesel NOx issue is expected to be solved by the upcoming changes to the EU emission regulations.

SCR Aftertreatment. In the sessions on emission aftertreatment, a number of papers covered various aspects of the selective catalytic reduction technology. Several presentations discussed the ongoing work to improve the low temperature performance of SCR, in terms of both minimizing the deposit formation and improving NOx conversion efficiency. Daimler [N. Kettmann] reported on their work to model the spray impingement limit for wall wetting with urea-water solution. Wall wetting experiments were conducted in a hot gas rig with a spray pressure atomizer for urea solutions and optical access using an IR camera. Three wetting regimes were identified, including dry wall, temporary wetting, and permanent wetting, the latter linked to the possibility of deposit formation. A model has been developed and validated to predict the temperature threshold between the wetting regimes. The model was further extended to include gas velocities. A map of operating conditions was generated to assist in the SCR development process and refinement of the urea dosing/regeneration strategy.

Pre-heating of urea solution before dosing has been suggested by Albonair [G. Hüthwohl] to improve low temperature SCR performance. In engine test bench experiments with a heavy-duty engine, electrical heating of 640 W was applied to urea directly before the nozzle. With the heating, the urea droplet size was reduced by some 50% and full urea evaporation/hydrolysis could be achieved at low spray rates. Deposit formation (at 170°C) was reduced with the heating by approximately 65%. A NOx conversion improvement at temperatures around 200°C due to urea pre-heating was equivalent to increasing the exhaust temperature by about 10°C.

More SCR developments targeting low temperature applications were presented, including an optimization of urea mixing using exhaust gas induced swirl [S. Kureti, TU Bergakademie Freiberg] and the use of gaseous ammonia as SCR reductant [J. Op de Beeck, Inergy]. In the latter concept, ammonia was stored as a solid compound in rechargeable “DiNOx” cartridges and released on demand onboard of the vehicle (the DiNOx technology was developed independently and is not related to the similar system by Amminex). A dual SCR system was proposed, with a close-coupled NH3-SCR and an underfloor urea-SCR catalyst.

Particulate Filters. With particulate emissions from diesel engines controlled to low levels by filters, GDI engines became the suspected major source of particulate pollution. A team from AFH Biel [J. Czerwinski] and VERT evaluated the performance of gasoline particulate filters (GPF) on various vehicles and under different operating conditions. The technology was found to be very effective in reducing PN emissions from GDI engines, including tests with increased lube oil consumption. GPFs were also tested on port injected gasoline engines. In many tests, GPFs showed a PN filtration efficiency in excess of 99% (GPF efficiency in mass produced vehicles is typically 70-80%, as this is sufficient to meet the PN emission standard).

Math2MArket GmbH [M. Azimian]—a spin-off from the Fraunhofer Institute for Industrial Mathematics (ITWM)—developed software to simulate filter media used for liquid and gas filtration. Through computer simulation, the GeoDict® software enables to reduce laboratory work while engineering new filter media. The company would like to expand the application of their software to diesel and gasoline particulate filter media. The software allows to simulate the deposition of soot particles, the pressure drop, and the depth and cake filtration regimes along the DPF channels.

The DYNTEST data logger by CPK Automotive [D. Bleicker] is used in many retrofit DPF applications for the monitoring and control of the particulate filter. CPK added a remote data communication functionality to their system via a new RemCo II module and a smartphone. The RemCo module encrypts the data from the DYNTEST data logger and transfers it via Bluetooth to the smartphone. Once the smartphone has access to the internet, it sends the data to a server, where the data can be accessed on a web portal by authorized users. This enables early discovery and predictive diagnosis of possible abnormalities and problems.

Engine Control. Bosch [D. Ruff] developed a model predictive control software for the diesel engine and the aftertreatment system that minimizes CO2 emissions while meeting a certain NOx emission limit. The method was discussed using an example diesel vehicle with a NOx adsorber catalyst (NAC) aftertreatment. The controller divides the task of NOx reduction between the engine and the aftertreatment, in a CO2 optimal way. This is achieved by coordinating different aftertreatment warm-up measures and the NAC regeneration strategy, and by tuning suitable engine parameters such as the air mass and injection timing. The software strategy, evaluated in a laboratory and in real driving, could provide a 1.5% CO2 improvement compared to the standard calibration of the vehicle.

* * *

The 16th FAD Conference will be held in Dresden on 7-8 November 2018.

Conference website: www.fad-diesel.de/conference-2017