IAV develops phase change cooling (PCC) WHR concept

9 December 2019

German consulting firm IAV has developed a Rankine cycle waste heat recovery (WHR) system they claim is capable of utilizing significantly more waste heat from diesel engines compared to previous approaches. Simulation data suggests that with ethanol as the working fluid, 8.0 to 9.3% BSFC reduction is possible under some operating conditions compared to 3.3 to 3.6% with more conventional approaches. Patents have been applied for [4587][4588] and a paper was presented at the 5th International Seminar on ORC Power Systems, September 9 - 11, 2019, Athens, Greece [4581].

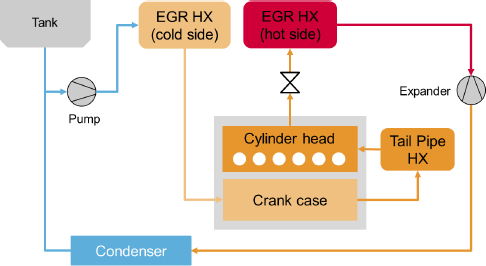

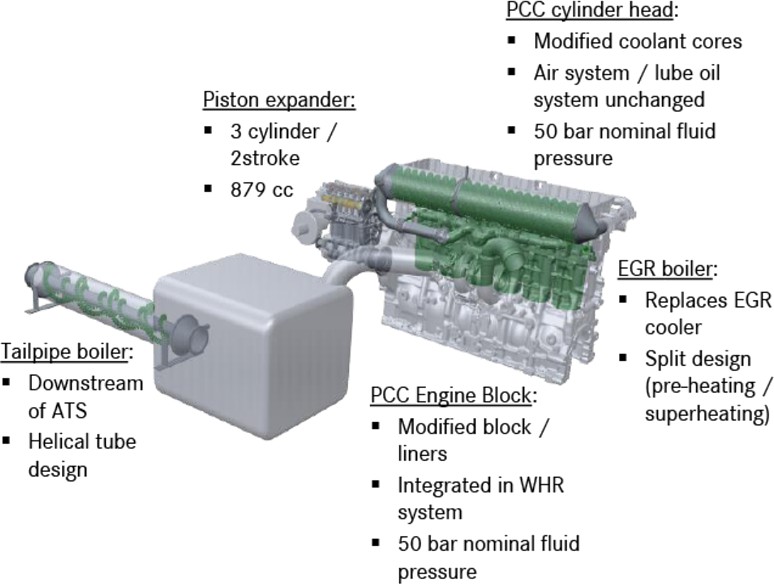

IAV’s phase change cooling (PCC) system, Figure 1, relies on passing the WHR system working fluid directly through the engine crankcase and cylinder head instead of using a secondary heat exchanger connected to the engine cooling system. The working fluid also acts as the engine coolant, and is evaporated in the process of passing through the engine and superheated via a hot side EGR cooler. The engine coolant passages require design changes to allow operation up to 6 MPa and to ensure adequate flow velocity to avoid hot spots.

By varying the system pressure and therefore the boiling temperature of the coolant, the engine surface temperatures can be varied independent of speed and load to reduce wall heat losses and encourage higher exhaust temperature at part load conditions while still maintaining sufficient cooling capacity at full load. An additional benefit is a reduced power demand by the coolant pump due to lower coolant flows. Separate WHR and engine coolant pumps can also be avoided.

Adequate engine cooling can be maintained at coolant pressures up to 6 MPa and temperature up to 275°C with adapted coolant duct designs. Estimates for a heavy-duty diesel engine at steady state operation between 1100-1300 rpm and 1000-1800 Nm suggest a BSFC reduction of 8.0-9.3% is possible with ethanol as the working fluid. This compares to a 3.3-3.6% reduction for a more typical ORC based approach using ethanol to recover waste heat from the EGR cooler and tailpipe exhaust gas.

In their 2019 DOE Merit Review presentation, Daimler shows that a phase change cooling system using a 60/40 water/ethanol mixture is being considered for their SuperTruck II program. They estimate a more modest 3.5% BTE potential at a highway cruise condition [4582]. The Daimler presentation acknowledges IAV.

While the BTE contribution estimated by Daimler is comparable to other SuperTruck WHR systems, the PCC approach simplifies the integration of WHR into the engine system by avoiding the need for a separate WHR fluid. It also allows ethanol based WHR fluids to recover heat from the engine coolant—more conventional WHR approaches typically require special organic fluids with a lower boiling point for this.

Source: IAV