Conference report: Integer Emissions Summit USA

17 December 2019

The 2019 Integer Emissions Summit USA was held on November 19-20, 2019 in Indianapolis, IN. The conference, attended by about 100 delegates, focused primarily on the planned California and US EPA low NOx emission standards for heavy-duty engines. There were also some discussion developments in nonroad engines, electrification and zero emissions technology.

Please log in to view the full version of this article (subscription required).

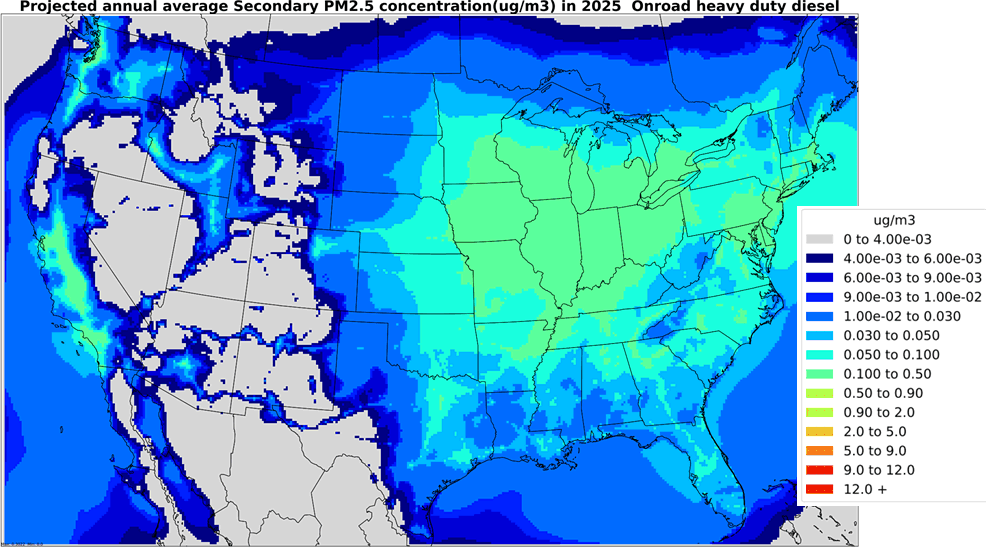

Low NOx Standards. While California has been presenting the case that further reductions of NOx emissions from on-road heavy-duty vehicles are necessary to address air quality, the same issue arises in many other parts of the US, Figure 1 [B. Nelson, EPA].

The US EPA and CARB are both working on regulatory initiatives to address NOx emissions from heavy-duty onroad trucks and some of these details were already reported. While it is expected that EPA and CARB regulations will align in 2027, California may see significant regulatory changes by 2024 that could lead to a temporary divergence in legal requirements for MY 2024-2026. While emissions from heavy-duty diesel engines are the primary focus, heavy-duty Otto cycle engines will also be required to meet similar NOx limits [B. Nelson, EPA][W. Robertson, CARB].

An important focus of the regulatory developments will be to reduce emissions during low load operation. In-use data from heavy-duty vehicles certified to 0.2 g/bhp-hr shows NOx at speeds lower than highway cruising speeds to be significantly higher than the current limit—this is further discussed below. The Low Load Cycle (LLC) will be an important part of the certification process to address emissions during low speed operation. Additionally, in-use compliance testing over normal operation will be implemented. In-use testing will evaluate idle, low load and mid-to-high load operation against respective certification cycle limits (idle, LLC and FTP). Further details of in-use testing elements were discussed at CARB’s September workshop [4591].

In-use monitoring and the alternative durability demonstration approaches depend heavily on further NOx sensor development for improved tailpipe monitoring performance. Current technology can take a long time (up to 20 minutes) before tailpipe data is available. Improved accuracy is also required for the low levels of NOx that need to be detected.

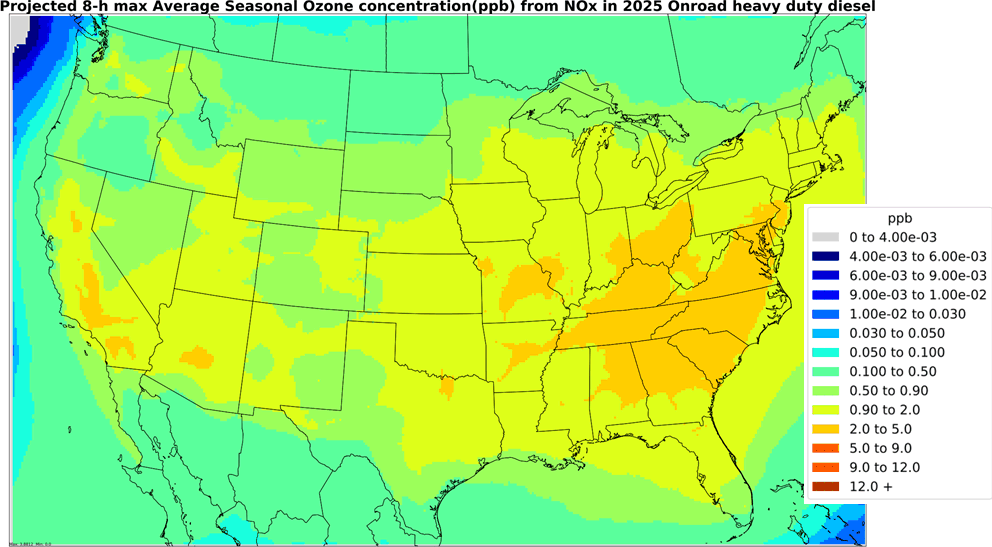

The ICCT presented findings from their recently published white paper [4589] assessing the real-world NOx emissions from heavy-duty diesel vehicles in the United States measured using portable emissions measurement systems (PEMS) [F. Posada, ICCT]. They analyzed data from manufacturer-run test results found in EPA’s Heavy Duty in Use Test (HDIUT) database. Data is from 160 PEMS tests on diesel engines certified to 0.2 g/bhp-hr NOx and included data from eight manufacturers and 26 unique engine families certified between 2010 and 2016. The data did not include engines certified using NOx credits or Cummins engines affected by an SCR recall. Some of their key findings included:

- The NTE protocol evaluates less than 10% of the total emissions data to determine compliance for heavy-duty in-use NOx emissions.

- A disproportionate amount of NOx emissions from heavy-duty vehicles is emitted during the low-speed operation characteristic of urban driving.

- Only at highway speeds, above 50 mph, do HDVs present average NOx emissions at the certification limit and below the in-use NTE emissions limit of 0.3 g/bhp-hr.

- Line-haul trucks have the highest average NOx emissions at less than highway speeds. Their average NOx emissions in urban driving are 1.41 g/bhp-hr, Figure 2.

- Line-haul trucks spend on average 43% of their time and emit 40% of the total mass of NOx in urban-like low-speed driving and idling.

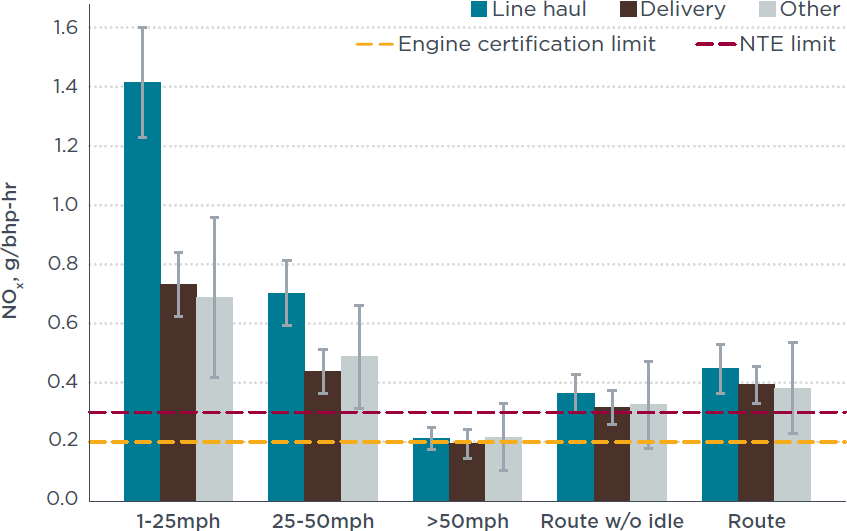

While not discussed in their white paper, the ICCT presentation also included a comparison with data from Euro VI HDVs, Figure 3. The Euro VI engines do better for NOx emissions under urban and suburban driving. Euro VI HDVs are subject to in service conformity (ISC) requirements intended to address real driving emissions. The NTE requirements for US engines are a result of Consent Decrees reached by the EPA with a number of engine manufacturers in 1998 and the focus is on ensuring compliance under highway cruising conditions.

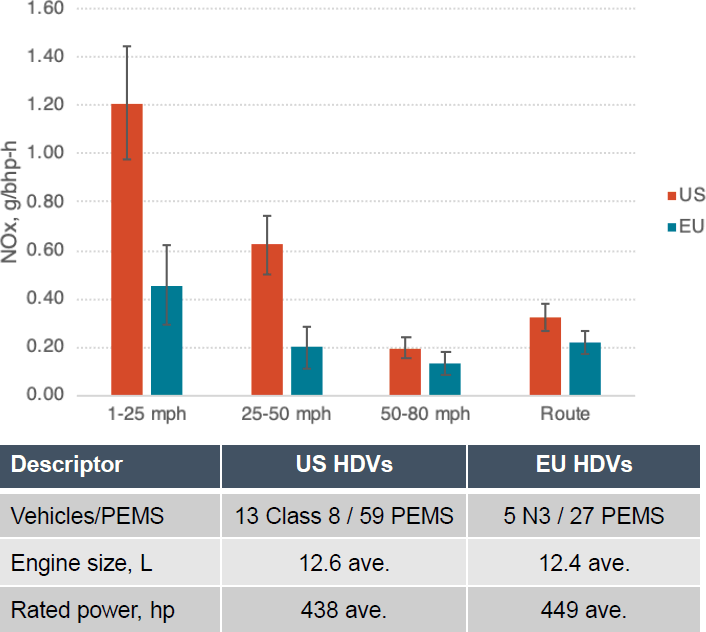

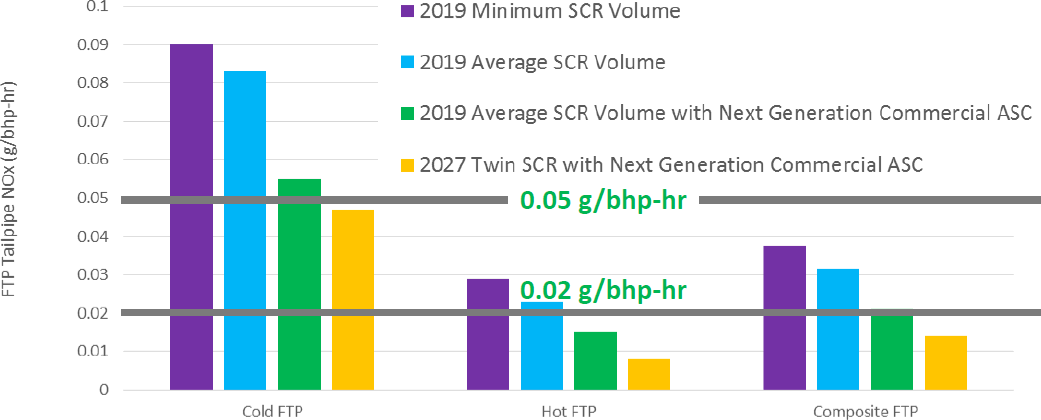

With regard to upcoming regulatory changes, MECA believes that by 2024 a 0.05 g/bhp-hr limit on the FTP is feasible without major changes to aftertreatment designs compared to current trucks [M. Geller, MECA]. Simulation work carried out at SwRI suggests that an aged 2019 aftertreatment system with better engine calibration can already meet a 0.05 g/ bhp hr FTP limit, Figure 4. By 2027, meeting 0.02 g/ bhp hr NOx over the FTP and about 0.075 g/bhp-hr on the LLC are achievable with advanced aftertreatment, engine thermal management technologies and improved calibration. Some of the technologies that might be required include heated urea dosing, cylinder deactivation and twin SCR systems with a close coupled SCR catalyst.

Southwest Research Institute presented some of the technologies they are developing [C. Roberts, SwRI]. Incorporating an aging model into the aftertreatment controller could allow urea dosing targets and regeneration frequency to be modified as catalysts age to ensuring emissions compliance over longer useful life periods and the >99.5% NOx reduction efficiency that would be required for a 0.02 g/bhp-hr limit. Catalyst discretization, i.e., modeling a catalyst brick as a series of discrete elements, could also be useful because deterioration mechanisms are not always uniform along the length of the component.

With dual dosing SCR systems, desulfation of the close coupled SCR catalyst will be required and will necessitate temperatures over 500°C every 500-1000 h with current fuels. Doing this without an upstream DOC will require that the engine generates the required temperatures. Cylinder deactivation could generate the required temperature at BMEPs as low as 1.5 bar.

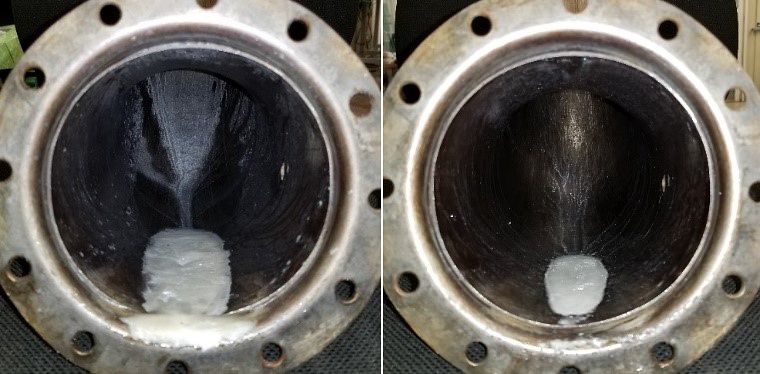

Deposit formation due to undesirable reactions of isocyanic acid can limit the lowest temperature at which urea dosing can be applied and thus cycle average SCR conversion efficiency. The threshold temperature for many current commercial engines is well over 200°C. One option is to additize the urea with an isocyanic acid (HNCO) hydrolysis catalyst and/or a surfactant [4590]. The hydrolysis catalyst, in this case ammonium titanyl oxalate (ATO), reduces the tendency of HNCO to form unwanted deposits while the surfactant reduces surface tension to improve the evaporation rate of water. The combination of the two additives can provide significant reductions in deposit formation, for example 72% at 180°C, compared to unadditized DEF, Figure 5.

Other Trends and Nonroad Engines. Argus media has a methodology they use to estimate urea consumption for SCR vehicles that involves estimating the size of the SCR equipped vehicle fleet. As a result, they are in a position to provide insight of future trends in SCR equipped vehicles [F. Cardoso, Argus]. Use of SCR in diesel engines will continue to significantly increase in the years to come. For heavy-duty, SCR equipped commercial vehicles are estimated to increase from about 15 million in 2019 to about 26 million in 2024 and is led mainly by growth in China. China has by far the largest commercial vehicle population and current SCR penetration is less than 25%. For the light-duty fleet, the numbers are estimated to increase from about 26 million in 2019 to 67 million in 2024 led mainly by growth in southern Europe where SCR penetration is currently low. While the future for diesel passenger cars in Europe is uncertain, light commercial trucks and vans will continue to be dominated by diesel engines. SCR is the technology of choice for the Euro 6d-TEMP standard that must be met by all registrations starting in September of this year.

By comparing estimated urea consumption to actual urea consumption, Argus is also able to estimate the amount of cheating that goes on. Several years ago, they highlighted this to be a significant issue in Brazil where as much as 60% of the fleet was not refilling urea tanks with urea. While the current level of cheating in Brazil has diminished, it remains in the 25-30% range. Other places where cheating is apparent include China, eastern Germany, Poland and the Baltic states.

In the next few years, CARB will be developing a Tier 5 off road diesel engine standard, including more stringent standards to reduce NOx and fine particulate emissions by up to 90% below the current Tier 4 standards [W. Robertson, CARB]. While no clear timeline is yet available, work could start in 2020. The current focus is to get the on-road Low NOx proposal ready for spring 2020. Some of the off-road research projects currently underway include: DPF and SCR aftertreatment for <37kW diesel engines that involves lab testing and field demonstration of hardware to achieving Tier 4f levels; baselining Tier 4f ‘SCR-only’ and ‘DPF-SCR’ OEM solutions with regard to criteria, GHG, and non-criteria emissions; and pursuing a Low NOx demonstration program for Off-Road engines.