Conference report: 11th International AVL Exhaust Gas and Particulate Emissions Forum

28 March 2020

The 11th International AVL Exhaust Gas and Particulate Emissions Forum was held on March 3-4, 2020 in Ludwigsburg, Germany. The conference was opened by an address by Prof. Helmut List of AVL, and included several keynotes and over 20 presentations on low-emission propulsion, exhaust gas aftertreatment, CO2 emission reduction, well-to-wheel considerations, renewable fuels as well as exhaust gas measurement technology. There were about 230 registrations, but the conference was attended by only about 170 participants, due to cancellations related to the Coronavirus travel restrictions.

Sustainable Transportation. The European Green Deal sets very ambitious—and ostensibly contradictory—policy targets of reducing GHG emissions and resource use, while maintaining economic growth. The Green Deal also aims to reduce pollutant emissions to very low levels, particularly in urban areas. These policy goals, in combination with the already adopted mandatory CO2 reduction targets designed to advance electric mobility, present a formidable business risk for European automakers. Engine and vehicle manufacturers have little choice but to shift significant resources toward the development of alternative powerplant concepts—such as electric and hydrogen-fueled vehicles of a limited commercial viability—while continuing along the development path towards a pollutant-free and CO2-neutral internal combustion engine.

The European policies, as well as the keynotes and presentations summarized below, were formulated and prepared before the Coronavirus pandemic. Depending on the severity of the ongoing crisis, corrections may need to be introduced to future policies and existing regulations, and some of the issues discussed in the past may become of secondary importance.

In one of the keynotes that opened the conference, Hermann Pengg of Audi presented the results of a life-cycle analysis to identify the most sustainable and cost-efficient future options for individual mobility. The work has been published as a book by Springer (in German). The authors considered several CO2 emission reduction scenarios, and used a cradle-to-grave lifecycle analysis combined with a total cost of ownership calculation. It was concluded that electric cars, combustion engine cars and fuel cell cars can all contribute to sustainable individual mobility in the future, but only if renewable energy carriers (electricity, liquid and gaseous fuels) are used in the operation. The cost of ownership analysis showed that electric vehicles (EV) offered lower emissions, but a higher ownership cost than petroleum fueled vehicles. Some of the best (most cost effective) powertrain options included hybrids and ICE vehicles powered by biomethane and synthetic liquid fuels. Among electric vehicles, the worst point was a battery electric vehicle (BEV) with the German electricity mix and a 50 cents/kWh electricity cost.

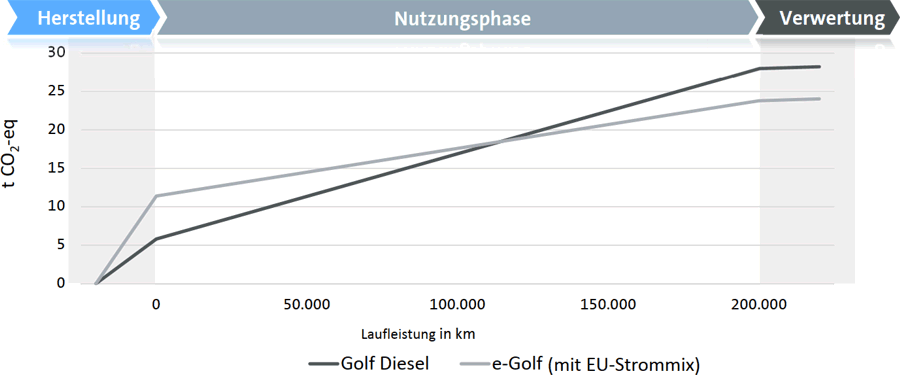

The carbon footprint of different powertrains was also analyzed by Volkswagen [M. Shüler]. VW has a target to reduce the lifecycle CO2 emissions from their entire new vehicle fleet by 30% by 2025, relative to 2015. Since about 50% of the lifecycle CO2 emissions of a BEV can be attributed to battery production, BEVs can offer a GHG emission advantage over diesel only after they accumulate a relatively long mileage. A compact BEV charged using the EU-28 electricity mix presents a GHG benefit after exceeding about 120,000 km, Figure 1. If German electricity mix is used, the diesel powertrain offers lower lifecycle GHG emissions even at 200,000 km.

EU-28 electricity mix. Herstellung = production; Nutzungsphase = usage; Ververtung = disposal.

Shell Global Solutions [K. Wilbrand] analyzed powertrain options for meeting the EU 2030 CO2 emission targets for light commercial vehicles (vans). A number of powertrains were compared, including conventional diesel, bio-CNG and hydrogenated vegetable oil (HVO) fuels, hybrids, hydrogen, and battery electric vehicles. Well-to-wheel emissions were studied for two operation types: city delivery and express (city to city) delivery. Diesel was found to be the least expensive powertrain option—not accounting for taxes, subsidies, or penalties for missing the mandatory CO2 targets. Today, vans have to meet a fleet-average tailpipe CO2 target of 147 g/km, which will be lowered by 31% by 2030. The penalties for exceeding the CO2 target are 95 euros per g/km per vehicle for van manufacturers, while fuel suppliers face a penalty of 470 euros per tonne of CO2 for missing the 2020 CO2 reduction target of 6% (relative to 2010) under the Fuel Quality Directive. Hence, the adopted tailpipe CO2 emission standards are expected to force increased sales of BEVs by 2030. Hydrogen allows zero-CO2 emissions and fast refueling, but it was found to be expensive. HVO and bio-CNG could offer CO2 reduction potential of over 70% at a moderate cost.

A key advantage of liquid hydrocarbon fuels is their high energy density, on the order of 12,000 Wh/kg, compared to 140-200 Wh/kg for Li-ion and 30 Wh/kg for lead batteries [M. Guschakowski, University of Braunschweig]. Therefore, in such applications as long haul trucking or aviation, it is not possible to replace high density chemical fuels with batteries. It is envisioned that “sustainable” liquid HC fuels could be synthesized via power-to-liquid processes such as Fischer-Tropsch synthesis. Electrofuels can be also produced directly via electrolysis processes from renewable organic precursors (e.g., levulinic acid) using renewable electricity. However, these processes require significant amounts of energy—the synthetic fuels are merely energy carriers (just like hydrogen), and not an energy source.

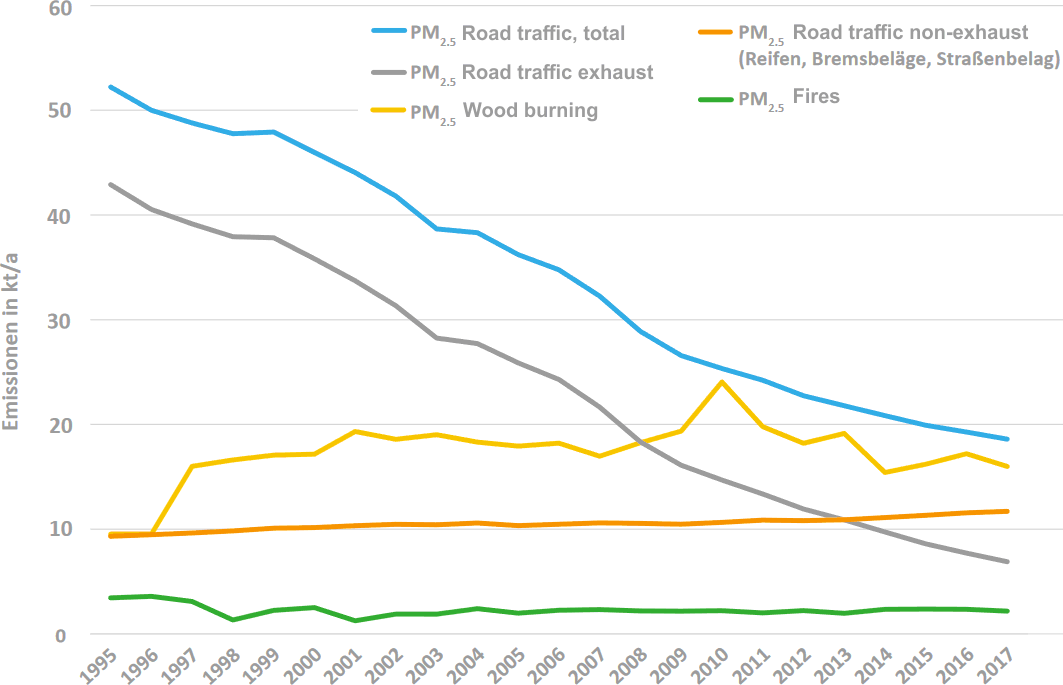

Mobility And Air Pollution The contribution of road traffic to the ambient fine particulate (PM2.5) inventories has been showing a strong declining trend [A. Dittler, KIT]. According to a 2019 report by the Leopoldina National Academy of Sciences, in Germany, PM2.5 emissions from road vehicle exhaust decreased by more than 80% since the mid-1990s, Figure 2. PM2.5 emissions from other sources—such as wood stoves, vehicle brakes, and road dust—are now more important than exhaust particle emissions. In Stuttgart, one of the most polluted cities in Germany, ambient PM2.5 concentrations are now very close to meeting the WHO 10 µg/m3 guideline.

These findings are supported by several air quality studies which show that ambient PM2.5/PM10 levels depend on ambient conditions [M. Klingner, Fraunhofer Institute], such as high sun intensity, atmospheric convection/inversion conditions, or rain prior to testing—suggesting that a large portion of the ambient PM2.5 must have originated from road dust and other non-exhaust sources. If so, electric vehicles will have little effect on PM emission levels in cities. However, electric vehicles could help reduce ambient NO2 concentrations. It should also be noted that the review did not consider particle number emissions.

As exhaust particle emissions are controlled to very low levels using diesel and gasoline particulate filters, non-exhaust emissions—including particle emissions from brakes and from tire wear—may become a major source of particle emissions from traffic. Typical WLTC emission factors for European brake pads are about 2×1010 1/km for PN emissions, while the brake PM emission factor can be similar to the Euro 6 exhaust PM limit of 4.5 mg/km [K. Augsburg, TU Ilmenau]. Under the coordination of the Joint Research Centre (JRC), the Particle Measurement Programme (PMP) has been developing a standardized test procedure for sampling and measuring brake particles, and a real world brake cycle. However, the adaptation of exhaust particle sampling and measurement technology to non-exhaust emissions is challenging. Several strategies for brake particle sampling have been considered, including a brake dyno (with the brake completely isolated from the environment), chassis dyno, and onroad real driving emissions (RDE) testing of brake particles. One of the challenges is that particle generation depends on the temperature of the friction ring, and temperature gradients and emissions are not uniform along the friction ring or over time. Initial experience with the experimental RDE and chassis measurement systems that have been implemented on vehicles also shows that the driver has a big impact on emissions. Potential control strategies for brake emissions include filters, coated discs, and regenerative braking. Tire wear emissions are another major source of airborne particles—results using a novel measurement methodology developed at the TU Ilmenau shows that between 0.5% and 1% of the total tire mass wear results in particles smaller than 5 µm. Emission limits for brake and tire wear particles have been considered for the upcoming Euro 7 regulation, but are unlikely due to the lack of repeatable measurement methodology.

Regulatory Trends. The European Commission has started the development of the next stage of EU emission standards, Euro 7/VII. These activities were discussed by Prof. Zissis Samaras [Aristotle University Thessaloniki], the head of the CLOVE Consortium that has been awarded a contract by the European Commission’s DG GROW for the study on post-Euro 6/VI emission standards. As Euro 6d vehicles consistently show very low emission levels, the main focus of the Euro 7 standards will be to ensure low emission levels under all real driving conditions. While certain tightening of emission limits (such as for NOx) can be expected and new limits may be added for some currently unregulated pollutants (such as NH3), the main objective is to design a post Euro 6 type approval process that would guarantee that vehicles are “as clean as possible” (1) under “all” driving conditions, and (2) over their entire useful life. In addition, vehicles should have “zero or near-zero emissions” in urban areas. These objectives are expected to be achieved through RDE testing and On-Board Monitoring. Laboratory testing would be used primarily for CO2 emissions and other non-RDE pollutants. To achieve near-zero emissions in the city using such powertrains as plug-in hybrids (PHEV), geofencing technology could be necessary. The Euro 7 in-use emission requirements may require a number of new OBD and sensor technologies, including sensors for PN, NH3, CO, HC, N2O and CH4 emissions. The Euro 7 proposal is expected in the second half of 2021, with implementation around 2027.

Jon Andersson [Ricardo] presented an overview of the EU programs on the measurement of sub-23 nm particle numbers. The research has developed modified sampling and measurement methodology that can account for particles smaller than the current 23 nm cut-off point and include all particles above 10 nm, for both laboratory (CVS) and RDE (PEMS) measurements. The research has been conducted under three programs: DownTo10 (the list of participants includes Aristotle University of Thessaloniki, Ricardo, AVL, and others), PEMS4Nano (Horiba, Bosch, TSI), and SUREAL-23 (APTL CERTH). Measurements that have been performed show that most vehicles are compliant with the Euro 6 PN limit of 6×1011 1/km for both > 23 nm and > 10 nm ranges. However, some technologies that can meet the current PN23 limit value would fail in the PN10 range. These technologies include, for example, certain types of CNG vehicles and performance motorcycles. The PM-sub 23 methodology will be finalized in mid-2020. A PM10 regulation is expected in the next 3 years, most likely before the Euro 7 regulation, and possibly in the form of a Euro 6e stage.

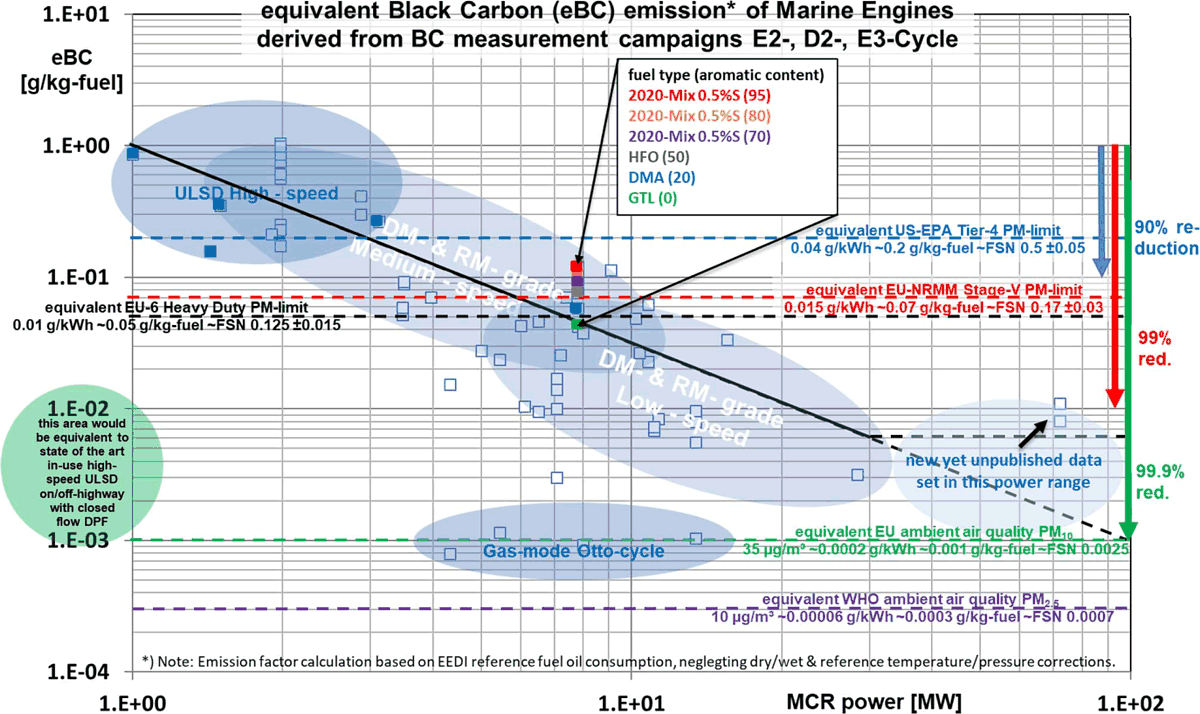

One of the focus areas of the International Maritime Organization (IMO) has been black carbon (BC) emissions from shipping [P. Lauer, MAN Energy Solutions]. BC has a high global warming potential (GWP100) and it reduces the snow albedo effect, which is especially harmful in the Arctic. IMO conducted several BC measurements campaigns from marine engines, Figure 3, which show that BC from marine engines can cover three orders of magnitude. Generally, the bigger the engine size, the lower the emissions. Marine fuel sulfur level has no impact on BC emissions, but aromatics do—low sulfur (0.5% S) fuel blends may increase BC emissions because they may have higher aromatics content than HFO.

Austria’s IIASA Institute [J. Borken-Kleefeld] discussed the monitoring of vehicle emissions via on-road remote sensing (Emission Detection And Reporting, EDAR) using absorption spectroscopy. A 20,000 Hz laser can be used for remote sensing of NOx, CO, HC and other emissions, providing instantaneous results per unit CO2/fuel. Data was presented on the correlation between remote sensing and RDE measurements, and results were shown from several remote sensing campaigns recently conducted in Europe.

Emission Aftertreatment. One of the main challenges in emission aftertreatment technologies is the cold start and low temperature performance of urea-SCR systems, as improved low temperature activity would be required for upcoming emission regulations, including both Euro 7 and the US EPA/CARB low NOx heavy-duty engine rule. One of the approaches under consideration, presented by Boysen [D. Knaf], involves placing the SCR catalyst upstream of the turbocharger. The concept, intended for light-duty applications, was developed in partnership with IVD and Umicore, and was supported by the German ‘DESIRE’ project. Two configurations were analyzed and validated using an ‘Engine-in-the-Loop’ test bed. In the first design, the urea dosing point was positioned downstream of a DOC. In the second configuration, there was no DOC and urea was injected directly onto an inner exhaust manifold wall for enhanced evaporation and droplet breakup, utilizing the highly transient flow characteristics. Both systems showed potential for the early start of urea injection, at around 260 s (160°C), over the WLTC cycle.

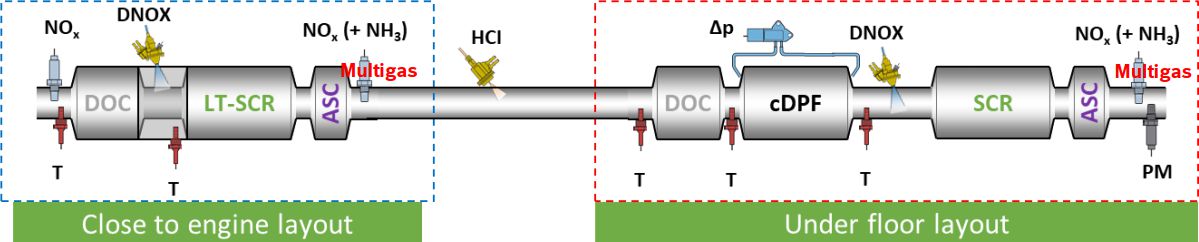

Bosch [J. Hammer] discussed their next generation Denoxtronic 8 SCR system for commercial vehicles. The system features dual urea injection, targeting US low NOx regulations and Euro VII, the latter expected to require 100-200 mg NOx/km. The dual injection SCR system seems fairly complex—it includes two full-blown SCR systems in series, one in the close-coupled and the other in the underfloor location, Figure 4.

The features of the Denoxtronic 8 system include: no back flow of urea; suction side filter; independently working injectors; extended range of maximum dosing up to 15 kg/hr; and ‘intelligent’ purging to avoid freezing. Bosch is also developing a multi-gas sensor capable of detecting NOx, NH3 and O2 for dosing control, N2O emission reduction, and catalyst OBD.

Active thermal management presents another approach to enhance the low temperature SCR performance. Fraunhofer Institute [R. Szolak] developed an active heating concept utilizing catalytic combustion, dubbed CatVap®. The device utilizes an Emitec electrically heated catalyst to oxidize fuel using oxygen in the exhaust gas (no extra air is required). The CatVap can be installed directly in the exhaust line (ΔP ≤ 10 mbar) or it can be operated on a bypass, using an exhaust gas flap, with ~10% of the total exhaust gas flow, to produce the temperature of 800°C at the device outlet. The device can be operated in two modes: (1) burner mode, and (2) oxidation catalyst mode. The burner mode uses a lean mixture, it can offer power levels of 12-20 kW, and can be activated immediately after cold start, just like a fuel burner. In the oxidation catalyst mode, the CatVap is operated with a rich mixture and can supply up to 36 kW of heat.

The temperature of the SCR catalyst can be also increased through optimization of the powertrain control strategy. TU Darmstadt [N. Hummel] presented an electrified evTrailer concept. The electrified trailer was a stand-alone hybrid system—with no data connection with the truck ECU—featuring its own battery pack and a charger, regenerative braking, electronics, and electric motors. By optimizing the evTrailer operating strategy, such as through reducing the electric support at low SCR temperatures, to increase the truck’s diesel engine load, the minimum SCR temperature could be increased from 123°C to 164°C, resulting in a 12% improvement in NOx conversion efficiency. The methodology was developed based on real world operation data of a Euro VIc diesel truck, and validated in engine bench testing.

The application of particulate filters (GPF) on gasoline direct injection (GDI) engines was discussed by A. Hochnetz [AVL List]. Since the Euro 6d stage, PN emission limits must be met in RDE testing (with CF = 1.5). Achieving the necessary “zero-mileage” GPF filtration efficiency may be challenging—it requires a suitable GPF substrate, coating technology, and preloading the GPF with ash in the production process. Equally important could be the optimization of engine-out PN emissions. The optimization of the engine-GPF system can be conducted using the AVL MOBEO semi-physical GPF modeling tool.

* * *

The 12th AVL Exhaust Gas and Particulate Emissions Forum is scheduled to take place in Ludwigsburg in 2022.