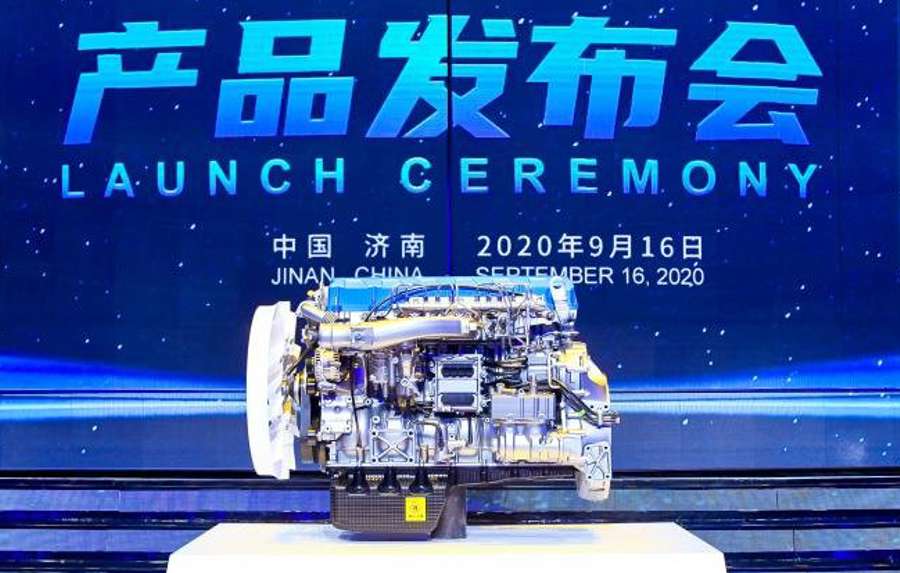

Weichai launches a 50% BTE diesel engine

16 September 2020

China’s Weichai Group has officially launched the first commercial, heavy-duty high-speed diesel engine in the world to have a brake thermal efficiency (BTE) above 50%.

During a launch ceremony held in China earlier today, Germany’s TÜV SÜD and the China Automotive Technology and Research Center—the country’s national internal combustion engine testing organization—awarded Weichai certificates for BTE of 50.26%. The engine was jointly unveiled by Ling Wen, vice governor of Shandong Province and academician of the Chinese Academy of Engineering; and Tan Xuguang, chairman of Shandong Heavy Industry Group and Weichai Group.

Since the development of the first diesel engine in 1897, the engine’s brake thermal efficiency increased from 26% to 46%, where it remained until now, according to Weichai. To further improve the diesel engine BTE, Weichai drew on its 70 years of experience in the internal combustion engine R&D. For the past 10 years, the company invested $4.4 billion USD in diesel engine development.

Since 2015, Weichai’s special technical research team has conducted a large number of simulations and bench tests to improve the efficiency of its engines, eventually leading to this historic breakthrough, the company said. Weichai credits the high brake thermal efficiency rate to five proprietary technologies: advanced fields synergy combustion technology, harmonious design technology, exhaust energy distribution technology, subzone lubrication technology, and WISE control technology:

- Weichai’s fields synergy combustion technology optimizes the design of the air passage, fuel injection, combustion chamber profile and other systems to make the relationship between the velocity field and concentration field in the combustion chamber more harmonious, increasing combustion speed by 30%.

- Harmonious design technology enables the diesel engine body’s to withstand high peak firing pressure (PFP), which greatly limits combustion improvement, by about 60%. The technology also strengthens the engine’s overall structure.

- The company’s exhaust energy distribution technology, developed in response to the increased difficulty of emission control caused by improved combustion, pioneered reconstruction of the exhaust system design. The technology adapts to the demand for exhaust gas recirculation while ensuring the efficiency of turbines, meeting regulations and standards, and achieving 1% increase in brake thermal efficiency.

- Subzone lubrication technology, developed based on the different characteristics of the friction pairs of the system, uses several friction reduction technologies to reduce the overall friction by 20%.

- WISE control technology takes advantage of Weichai's self-developed ECU by developing a series of more precise control predictive models, making every part of the diesel engine more efficient.

Weichai’s achievement is a historical moment in the development of internal combustion engines, the company said. Several diesel engine experts including Bosch, AVL, FEV, SAE, China Machinery Industry Federation, China Internal Combustion Engine Industry Association, and China-SAE congratulated Weichai on this breakthrough and praised the company for setting a new benchmark for the diesel engine BTE.

The Weichai 50% BTE engine has a 13 L displacement, is rated at 560 hp at 1900 rpm, and utilizes a 2500 bar fuel injection system. The engine meets China VI/Euro VI emission requirements. Increasing brake thermal efficiency from 46 to 50% reduces diesel fuel consumption and CO2 emissions by 8%.

Weichai said it has received strong support from Bosch Group and other global suppliers and R&D consulting firms in the development of this program. Weichai’s future plans include partnering with more global companies to move toward a goal of 55% thermal efficiency, Chairman Tan Xuguang announced during today’s ceremony.

Until now, a 50% BTE has been only commercially available in large, low-speed, two-stroke marine diesel engines.

Source: Weichai