Conference report: SAE WCX 2023 Congress

28 April 2023

The SAE 2023 WCX World Congress Experience was held on April 18-20, 2023, in Detroit as an in-person event. There were about 4800 registered participants. The three-day schedule included about 834 technical papers as well as keynote speeches, discussion panels, and oral-only presentations covering all areas of automotive technology. The following summary details several noteworthy WCX 2023 talks on engines and engine emission topics.

Please log in to view the full version of this article (subscription required).

Ameya Joshi of Corning presented a technical keynote on recent developments in vehicle efficiency and emissions [5757]. Included was a summary of challenges related to the proposed Euro 7/VII regulations, EPA 2027 heavy-duty regulations and the proposed EPA 2027 light-duty regulations.

Challenges for light-duty vehicles with Euro 7 include reducing cold start emissions down to -10°C and controlling newly regulated species such as ammonia. The inclusion of solid particles down to 10 nm in PN, longer durability requirements and onboard monitoring present additional problems.

While many current Euro 6d-temp and Euro 6d gasoline light-duty vehicles can already achieve Euro 7 NOx levels, cold start NOx, HC and PN emissions down to -10°C, ammonia and CO emissions may require technical changes. Cold start gaseous emissions could be addressed with improvements in TWCs through larger volumes, lower thermal mass substrates, and more aggressive exhaust gas thermal management that could include electric heaters or fuel-fired burners. Control of PN emission could be addressed with some combination of fuel injection and combustion system improvements and improvements in GPF filtration efficiency. Ammonia emissions may require an ammonia slip catalyst that will be different from the technology used to limit ammonia in diesel engines because of the need to work under varying lean-rich conditions and high temperature can deactivate a diesel ASC. Limiting CO emissions will require reductions in fuel enrichment at high load.

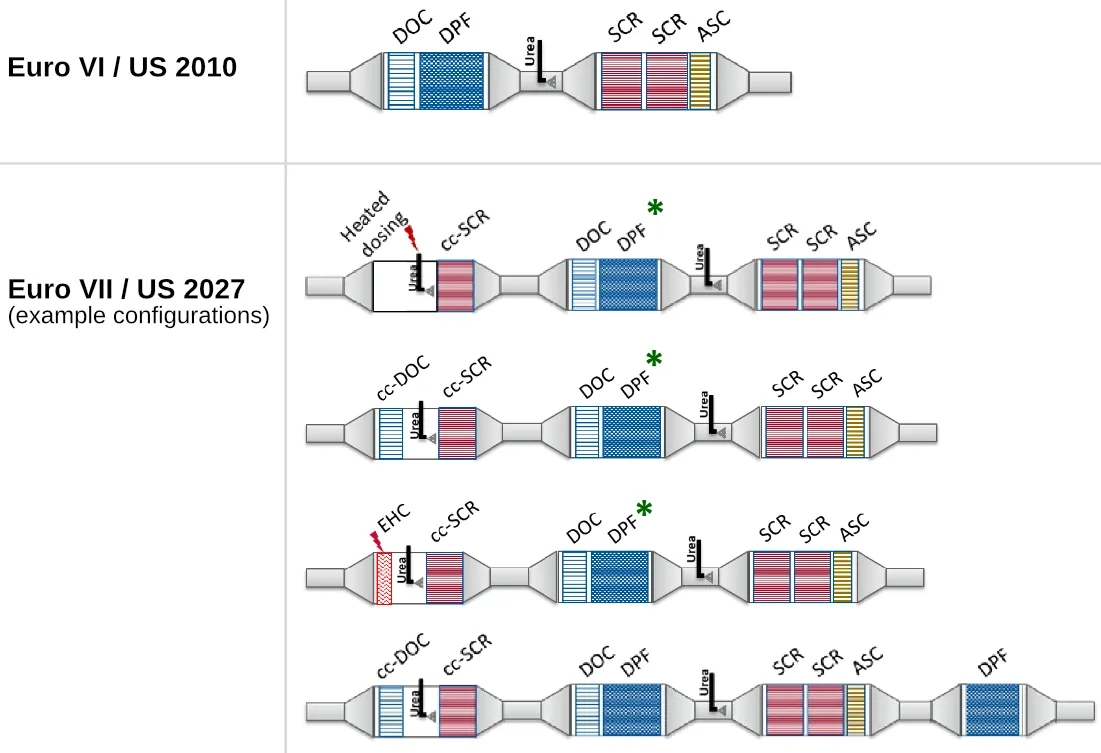

Figure 1 illustrates some possible aftertreatment systems that could meet upcoming EPA/CARB 2027 and Euro VII emission limits. While the NOx limits in the Euro VII proposal are considerably higher than those for CARB/EPA 2027, proposed changes in ISC testing may require similar NOx control options in Europe and North America. Limiting N2O emissions for both jurisdictions will likely see further optimization of catalysts.

* DPFs with higher filtration efficiency relative to 2010/Euro VI systems

Emission Control

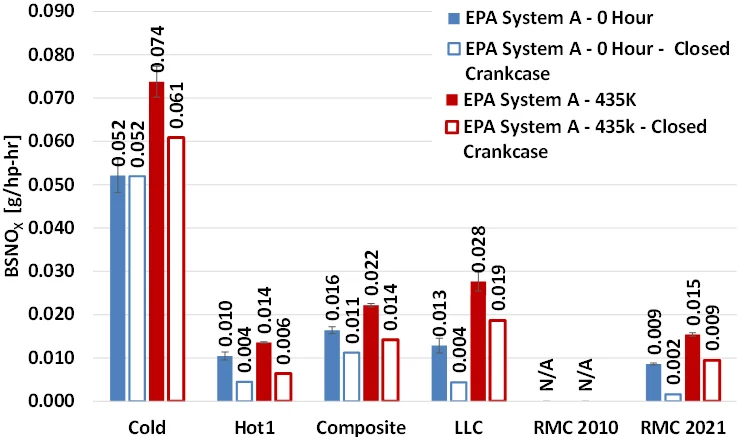

SwRI provided an update on the ongoing low NOx engine demonstration program [5758]. Emissions of NOx with the EPA System A are summarized in Figure 2. While past results have struggled to show a comfortable engineering margin for the CARB 0.02 g/bhp-hr/435 k mile limit, recent work demonstrated that further NOx reductions of about 6 mg/bhp-hr could be achieved by adopting a closed crankcase ventilation system to bring FTP composite emissions at 435k miles to 0.014 g/bhp-hr. The effect of an electric heater mounted in front of the LO-SCR catalyst was also evaluated and found to provide CO2 reductions of 1.5% and 3.2% on the composite FTP and LLC cycles respectively with a heater power of 2.4 kW. The electric heater was powered by the engine and therefore the fuel consumption and CO2 required to generate the electricity was accounted for.

SwRI also evaluated the effect of low ambient temperature on the EPA System A using the upcoming MAW-based in-use testing requirements using a system aged to the equivalent of 800k miles. Testing was done in a test cell using the CARB Southern NTE cycle that is dominated by highway driving as well as the LLC. While compliance was maintained with the LLC cycle and the idle and low load bins of the CARB Southern NTE cycle, the medium/high load bin of the latter proved to be a challenge. Three contributing factors were identified, 1) delayed warm-up, 2) low aftertreatment system temperature during the increased engine loads following an extended idle period and 3) inadequate ANR (NH3/NOx) on the downstream SCR catalyst. The first two issues would require additional measures to increase the exhaust temperature or to enable rapid warm-up while the third issue could be resolved with additional calibration updates. A dedicated calibration for low ambient temperatures may be required [5759].

In work carried out at SwRI, Eaton evaluated several technologies that could be used independently or combined to achieve 2027 heavy-duty emissions levels while remaining CO2 neutral or better. The technologies included cylinder deactivation (CDA), LO-SCR, electric aftertreatment heating and fuel burner technologies. While none of these were able to meet the requirements on their own, the combination of CDA and LO-SCR was able to meet the NOx requirements over both the FTP and LLC with a comfortable margin while remaining CO2 neutral on the FTP and providing a 3.8% CO2 reduction on the LLC. Adding an electric heater to this combination further increased the FTP NOx margin and provided further CO2 reductions over the LLC. The electric heater was powered by the engine and would have increased the engine load and exhaust temperature during idle and low load operation [5760].

Particle Filters

In addition to lower PN limits, the “intended use” clause for ISC testing in the proposed Euro VII proposal presents a significant challenge for PN emissions and DPF technologies developed for Euro VI may not be adequate. Corning demonstrated that one challenging condition for PN emissions during ISC testing is high speed driving. Under such conditions, DPF inlet temperature and NOx/soot ratios can be high and passive DPF regeneration can burn-off much of the soot cake that many current DPFs rely on to achieve high filtration efficiency. While the resulting PN slip can be problematic for some filter technologies, options are available that can keep the PN emissions under control. While details were not provided, four DPFs that differed in microstructure and surface pore characteristics were evaluated and with two of them providing sufficient filtration efficiency to address this challenge [5765]. Similar work by NGK demonstrated that under this type of driving condition, sufficient PN filtration efficiency can be achieved by reducing larger pore volume (D90) in the DPF. To minimize increases in backpressure, smaller pore volume (D10) was decreased [5766]. A layer coating applied to the inlet channels is another option [5767]. Similar technologies are also being developed for GPFs [5768].

While the use of a secondary DPF after the SCR catalyst for controlling urea generated PN emissions has been discussed before, NGK demonstrated that such a filter with a high porosity and small MPS can keep PN emissions below about 1010/kWh and back pressure increases below 1.2 kPa that represents less than 5% of overall backpressure [Wells, A. - Oral only].

Engines

Achates updated ongoing work on their 10.6 L opposed piston diesel engine by presenting some in-use testing results. In-use testing has been carried out at least twice. During the first attempt, some operating conditions made NOx control challenging. After the aftertreatment system was upgraded and recalibrated, in-use NOx results were reported as 0.10 g/h for bin 1, 0.006 g/bhp-hr for bin 2 and 0.007 g/bhp-hr for bin 3. No details on the in-use testing conditions were reported. The aftertreatment system uses BASF catalyst formulations, Corning substrates and an Eberspächer insulated can. NOx emissions over the FTP, RMC and LLC were reported as having margins of 10%, 75% and 87% respectively. These translate to approximately 0.018 g/bhp-hr, 0.005 b/bhp-hr and 0.007 g/bhp-hr respectively [Fromm, L. – Oral only].

Colorado State University, in a paper co-authored by Cummins and Woodward, presented work on a natural gas fueled engine utilizing controlled end gas autoignition (C-EGAI). Using a single cylinder version of Cummins X15 diesel engine, three different piston bowl geometries were evaluated. A peak BTE of 48.5% was reported with one of the engines using 30% EGR and at an IMEP of 16.6 bar [5769].

In another paper on natural gas engines, Michigan Tech reported achieving compression ignition of natural gas in a single cylinder version of Cummins X15 engine. This was achieved with a compression ratio of 23.6:1, 160°C intake air temperature and 8 bar boost pressure. BMEP was limited to about 16 bar due to peak cylinder pressure considerations. A pilot injection was required to achieve stable combustion. Ignition delay was reported as 1.6 ms [5770].