Conference report: CIMAC Congress 2025

11 June 2025

The 31st CIMAC World Congress was held in Zurich, Switzerland on May 19-23, 2025. The CIMAC Congress, organized once every three years, is the key meeting that covers large internal combustion engine technology, including engines for ship propulsion and power generation. The program included more than 200 technical papers presented in four parallel sessions, two discussion panels, and poster sessions, while the evenings were filled with remarkable social events. The event also included an exhibition and technical tours to WinGD, Accelleron, DUAP and other Swiss-based engine technology companies. The Congress was attended by nearly 1,000 participants from over 20 countries—a notable increase compared to the prior Congress held in Busan in 2023.

Please log in to view the full version of this article (subscription required).

The central theme during this years’ Congress was decarbonization of internal combustion engines (ICE) used in marine applications and in power generation. Most papers on new engine concepts covered dual fuel engines capable of operation on low-carbon fuels—with a focus on ‘green’ ammonia and methanol. Other topics included digitalization of shipping, fuels and lubricants, fuel injection, turbochargers, emission reduction, as well as carbon capture and storage (CCS).

A key driver of the marine industry decarbonization effort is the International Maritime Organization’s (IMO) 2023 GHG Strategy, which calls for a GHG emission reduction from shipping by 20-30% by 2030 compared to 2008 levels, 70-80% by 2040, and for reaching ‘net-zero’ GHG emissions by 2050. Furthermore, 5% of shipping’s fuel is to be zero emissions by 2030. The IMO Strategy is expected to be supported by GHG fuel intensity (GFI) targets and pricing mechanisms, however, the GFI measures have not yet been finalized and it is still unclear how the proposed GFI pricing mechanism would be implemented—the IMO is a United Nations agency without any enforcement or taxation powers.

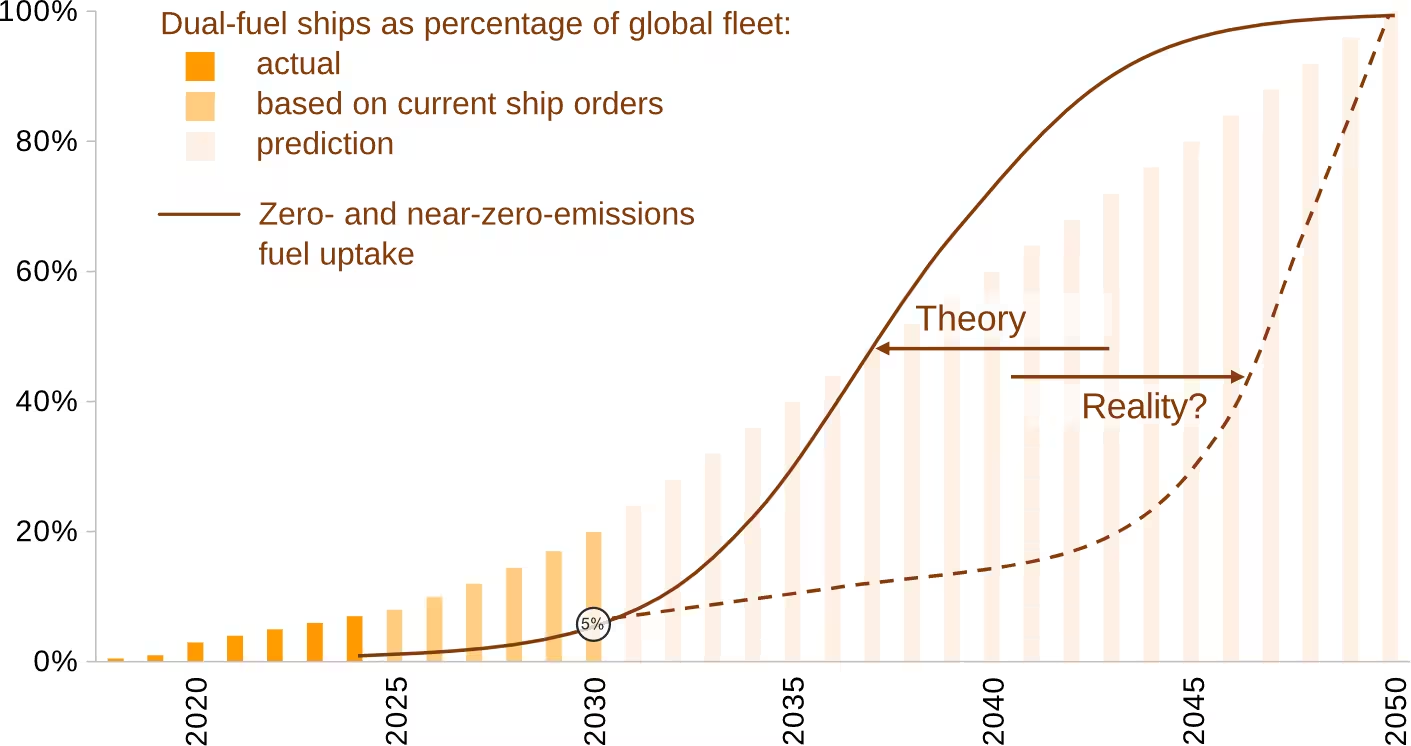

The decarbonization outlook for the marine sector was discussed in a panel with the participation of speakers from the ship-building, shipping, and marine fuels industry. Dual fuel engines are the key pathway for the adoption of alternative, low-carbon fuels [C. Rofka, Accelleron]. While only about 7% of total current fleet is dual fuel capable, about 40% of new ships on order are dual fuel ships, and a fleet of 100% alternative fuel capable ships may be feasible by 2050. However, a wider adoption of alternative fuels may be pushed into the future—it would require substantial investment decisions, while alternative fuels are not cost-competitive with conventional fuels. There is no business case for energy companies to supply alternative marine fuels such as ammonia [A. Ebbinghaus, Shell]. Therefore, a future scenario is emerging where the global shipping fleet is equipped with alternative fuel capable engines that continue to operate on fossil-based diesel fuels.

(Courtesy of Accelleron)

Ammonia Engines

Ammonia not an ideal combustion engine fuel—it has a narrow flammability range, low flame speed, high heat of vaporization, and high auto-ignition temperature. The effects of low flame speed propagation include low thermal efficiency and emissions of unburned NH3. Ammonia combustion also produces emissions of NOx and N2O, the latter a greenhouse gas with a high global warming potential of 273, the control of which may require new catalyst technologies. Still another challenge is presented by ammonia toxicity and the need for adequate safety systems onboard ammonia-fueled ships.

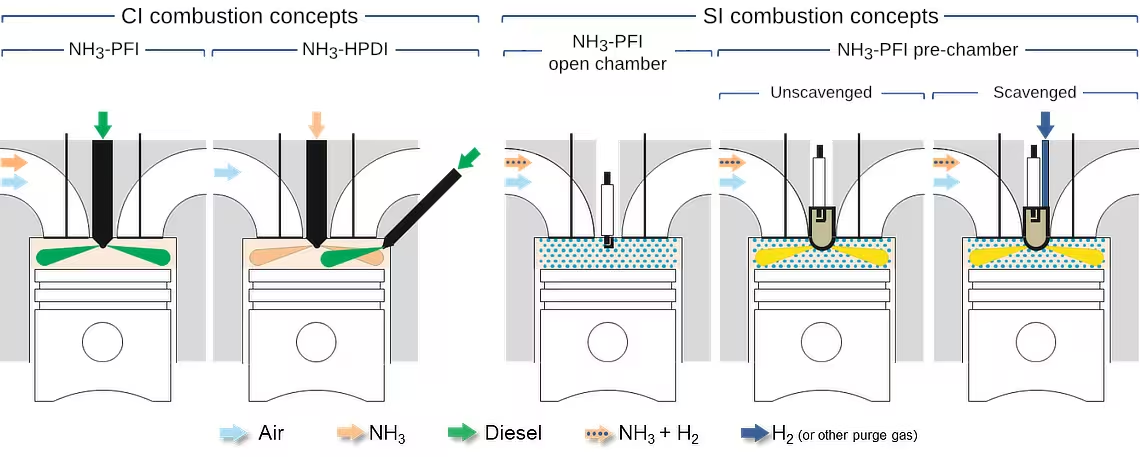

A number of ammonia engine concepts have been under development, including both compression ignition and spark ignition engines, Figure 2. In most CI engines, a dual fuel strategy is used such as ignition with a diesel pilot. In many SI implementations, hydrogen is added to ammonia to facilitate ignition. This hydrogen can be supplied as an external gas stream or else it can be generated through ammonia decomposition. An ammonia cracker concept was developed by LEC GmbH, where an electrically heated catalyst is used to promote partial oxidation reforming of NH3 [6460]. The cracked gas includes H2 as well as NH3, N2 and water vapor. However, the N2 dilution and the presence of H2O could impact the ignition process if the cracked gas is added directly to a pre-chamber, as opposed to the inlet air charge.

(Courtesy of LEC GmbH)

WinGD discussed the development of ammonia engine technology for its new X-DF-A family of two-stroke, large-bore, dual fuel engines [6462]. A diesel pilot fuel share ratio as low as 5% was achieved. Engine-out NH3 emissions below 10 ppm and N2O below 3 ppm were reported across the operating range. Key ammonia safety measures include (1) a gas-safe machinery space concept that ensures no ammonia release in the event of a malfunction; (2) a double-wall piping system that provides secondary containment and early leakage detection; and (3) a purging concept for safe removal of ammonia during fuel changeovers, in case of leakages and during maintenance. The X-DF-A technology is being implemented in a commercial large-bore ammonia engine, claimed to be the world’s first, currently in final assembly.

A marine two-stroke ammonia engine is also being developed by MAN Energy Solutions (MAN-ES) [6471]. The MAN B&W ME-LGIA engine utilizes high pressure direct injection of ammonia with diesel pilot ignition. Full engine operation on NH3 over 25%-100% load was demonstrated, with a diesel pilot of around 5% of the specific fuel consumption and efficiency similar to diesel. NOx emissions were controlled using SCR. Engine-out N2O was typically below 5 ppm and no N2O was formed over the SCR catalyst.

Another paper by MAN-ES described ammonia safety systems developed for the ME-LGIA engine [6472]. The engine is fueled by liquid anhydrous ammonia supplied at a pressure of 80 bar to prevent boiling and cavitation in the fuel system. In the injector, ammonia is further pressurized to 600-700 bar by oil under pressure, with a separate oil barrier system separating ammonia from the hydraulic oil. An ammonia release mitigation system is implemented that utilizes water to absorb ammonia vapors. The NH3 fuel is supplied to the engine room using a double wall piping system, using a fan to ensure negative pressure in the outer pipe. If the maximum ammonia concentration is exceeded, the system automatically switches to diesel operation. The NH3 fuel tank itself is located in an enclosure with forced ventilation. If the maximum NH3 concentration is exceeded in the fuel tank enclosure, a water curtain is applied to absorb ammonia, and the waste water is collected to a collection pool.

Wärtsilä presented their ammonia four-stroke dual fuel engine, Wärtsilä 25, that was launched in 2023 [6476]. The W25 ammonia engine is similar to the LNG version—on a system level, the main difference is the addition of an ammonia release management system. In case of a failure, the engine switches to diesel mode. In the ammonia mode, the engine delivers 305 kW per cylinder, compared to 375 and 345 kW for diesel and LNG, respectively. The ammonia share in the gas mode is about 90% throughout the load range. For IMO Tier III compliance, SCR aftertreatment is used to reduce NOx and NH3 emissions.

IHI Power Systems reported on the development of a four-stroke ammonia-fueled marine engine utilizing a pre-mixed combustion with diesel (MDO) pilot ignition [6461]. The initial ammonia combustion experiments were conducted using a ‘rapid compression machine’ (RCM), capable of simulating the temperature and pressure in the combustion chamber of the actual engine. This was followed by a single cylinder, 5 L engine and full scale engine tests on the 6L28ADF engine (1,618 kW @750 rpm). Over 90% NH3 fuel share ratio was achieved, with engine-out ammonia emissions of around 1%. These emissions, as well as NOx, were controlled using an SCR catalyst, while an additional catalyst was used to reduce N2O from about 20 ppm to 10 ppm.

In another talk, IHI discussed the development of a single fuel spark ignition ammonia engine without H2 ignition assist [6473]. Initial trials with an open combustion chamber suffered from slow combustion. Better results were obtained using a pre-combustion chamber (PCC) with a PCC spark plug. The researchers were able to optimize the PCC shape to obtain stable NH3 combustion in a single cylinder engine.

The development of a single fuel ammonia engine for power generation was reported by Innio Jenbacher [6465]. The Jenbacher Type 4 ammonia engine was equipped with a high energy spark ignition system. The fuel system included a liquid ammonia storage followed by an NH3 evaporator. An electrically heated NH3 cracker provided a small fraction of H2 as ignition promoter at part load. Hydrogen was not needed at full load operation (22 bar BMEP). Emissions of NOx and NH3 were controlled by an SCR catalyst. Engine-out N2O was at 20-25 ppm. In future work, the developers target an 80% N2O reduction using a catalyst.

The Oak Ridge National Laboratory investigated ammonia-diesel dual-fuel combustion in a high-speed 4-stroke engine [6477]. The experiments were conducted in a Cummins ISB 6.7 L engine converted to a single cylinder operation, with ammonia energy substitution of 90-96%. The achieved indicated efficiency was similar to diesel. The key issues included a high fuel slip (NH3+HC) of 10-15% for dual fuel NH3-diesel operation, as well as emissions of NOx and N2O.

Hydrogen Engines

Hydrogen is also a challenging combustion fuel, in ways that are opposite to ammonia fuel. Hydrogen is characterized by a wide flammability range and fast flame propagation, which makes it prone to abnormal combustion phenomena such as pre-ignition. Additionally, due to its low volumetric energy density, hydrogen is not suitable as fuel for ocean going ships or other large mobile engines.

In a collaboration between MAN-ES and Mitsui, the Mitsui E&S test engine—the four-cylinder and 50 cm bore two-stroke 4S50ME-T diesel engine—was rebuilt to operate one cylinder on hydrogen, with the three remaining cylinders operated on regular diesel [6466]. Pilot fuel injection was utilized for stabilizing the ignition around TDC, using the ME-GI methane engine hardware. Tests with pre-injection of hydrogen, mimicking premixed operation, showed that it was very difficult to run a marine two-stroke engine with a premixed Otto-like operating mode when using hydrogen—it was not possible to avoid severe preignition of the hydrogen charge in these tests. In the Diesel mode, on the other hand, the hydrogen combustion largely behaved like methane combustion in a normal ME-GI engine. However, NOx emissions were on average 49% higher for hydrogen compared to diesel. Regardless of the test results, MAN-ES indicated that hydrogen is not a viable fuel for two-stroke marine engines due to excessive fuel storage space onboard ships that would be required.

Wabtec conducted a preliminary investigation of hydrogen-diesel dual fuel operation on a locomotive engine equipped with their NextFuel LNG/CNG port injection system [6467]. The engine was adapted for H2 operation by installing crankcase explosion relief provisions. The H2-diesel operation was prone to abnormal combustion, particularly pre-ignition, which increased with increasing rail pressure and with later ignition timing. NOx emissions initially increased with increasing H2 substitution ratio (SR), then decreased with SR above 60%.

Several papers discussed co-firing of hydrogen in natural gas engines used for power generation. The underlying concept involves the use of ‘green’ hydrogen for energy storage and grid stabilization applications. While this concept appears far-fetched—converting renewable electricity into hydrogen to reconvert it later into electric power incurs massive efficiency penalties—it still finds support, most notably in Europe, where according to some expectations hydrogen and other e-fuels could be imported in the future from South America and Africa.

H2 co-firing projects were reported by Wärtsilä [6478], Mitsubishi Heavy Industries [6479], and Kawasaki [6480]. The hydrogen blend ratios targeted in these projects ranged from 25% to 50%. Abnormal combustion that occurred at higher H2 substitution ratios was mitigated by such means as derating the engine and reducing the compression ratio. The paper by Kawasaki [6480] also reported on the testing of a 100% H2, single cylinder, spark ignited pre-chamber engine.

Power-Gen Engines in Renewable Grids

A session on operator’s perspective provided interesting insights on the operation of natural gas power generation engines in grids with increasing contributions of wind and solar power. Renewable power generation is highly variable depending on weather, which demands increasingly more flexible generation [6490]. As wind and solar power often has the “right” to go first into the grid, it is a source of technical and economic challenges related to load balancing and electricity pricing for natural gas generators.

Kawasaki used their KG series engines as an example to discussed flexible operation of natural gas engines for grid power stability [6491]. In lean-burn, turbocharged gas engines, rapid load increases can cause abnormal combustion due to insufficient intake air pressure caused by turbo lag and fluctuations of the air-to-fuel ratio. To address the issue, Kawasaki has developed a rapid start-up system with improved combustion control, intake air pressure control, and improved turbocharger responsiveness. In order to quickly respond to the changing demand, there is also a need to operate engines in a standby mode, rather than to shut them down. This, however, results in increased emissions. An intermittent gas injection strategy has been developed that can reduce emissions of unburned gas at low engine loads by as much as 85%.

IHI Power Systems discussed the development of an automated power generation scheduling system aimed at efficient operation and increased powerplant profitability [6492]. The automated system, dubbed e-NESTY, obtains price prediction data for the power market based on weather forecasts, the season of the year, the day of the week, and time. Based on the forecast electricity price, engine start-ups and the power generation output are controlled to maximize profit, considering the required usage and the price of natural gas. Some early experience with the e-NESTY system showed a 29% increase in power generation and a 1.6% increase in profit, compared to the conventional scheduling process by a human operator.

Methanol Engines

Methanol is arguably the least challenging alternative fuel, with some ships already operating on methanol. The Diesel cycle combustion (with a pilot ignition) allows for high, 90-95% fuel replacement rate, diesel-like efficiency and high power density in the methanol mode. Pre-mixed combustion—such as using port fuel injection (PFI) in four-stroke engines—offers lower fuel replacement rates of 70-80% and reduced efficiency, but can provide an easy retrofit solution for existing engines [6463].

WTZ Roßlau conducted an experimental investigations of a methanol dual-fuel combustion process on a 5.17 L PFI single cylinder research engine [6485]. It was shown that the gradual substitution of diesel fuel with methanol can be limited by a sharp increase in ignition delay and associated high maximum cylinder pressure gradients. For an optimal methanol dual-fuel combustion process, the study recommended the earliest possible center of combustion and the lowest excess air ratios. In another combustion study, Daihatsu Diesel experimented with methanol-DME blends to improve the ignitability of methanol and shorten the ignition delay [6486].

Methanol combustion can produce new types of pollutant emissions, not encountered in the diesel engine. VTT Technical Research Centre of Finland studied dual fuel methanol-diesel combustion on a single cylinder PFI engine and found that while NOx emissions could be reduced with methanol, methanol-diesel combustion produced high formaldehyde emissions (1.1 g/kWh) and high levels of unburned CO and THC—the latter composed mostly of methanol—representing 5% of the engine’s fuel consumption [6487].

Engine manufacturers provided an update on the development of commercial dual fuel methanol engines. The development of two-stroke methanol engines was reported by Hyundai Heavy Industries (HiMSEN engine) [6481] and by WinGD [6482]. Both engines utilize the Diesel cycle with high pressure (~600 bar) direct injection of methanol. In both cases, first engine prototypes are expected to be ready this year.

Development of a commercial four-stroke dual fuel methanol engine was reported by Daihatsu Diesel [6483]. The engine, with a bore of 330 mm, utilizes a dual fuel injector and the HPDI operating principle. A methanol leak detection system has been developed, which is required by marine classification rules for ships with methanol fuel.

Another four-stroke development was discussed by Yanmar [6484]. A PFI system was chosen for the first application—a small-bore, 1 MW-class marine generator engine. The engine employs variable valve timing and achieves an almost 80% methanol mixing ratio. The emission aftertreatment includes a diesel oxidation catalyst for the reduction of methanol and HCHO emissions and an SCR system for NOx reduction.

* * *

The 32nd CIMAC World Congress will be hosted by the CIMAC National Member Association (NMA) Netherlands and Belgium in May 2028.