1997 Cummins B3.9-C EPA Tier 1 nonroad engine with muffler and retrofitted with a 6 liter DPF

DieselNet Technology Guide » Diesel Exhaust Gas

DieselNet | Copyright © ECOpoint Inc. | Revision 2007.03a

This is a preview of the paper, limited to some initial content. Full access requires DieselNet subscription.

Please log in to view the complete version of this paper.

Engine exhaust back pressure is defined as the exhaust gas pressure that is produced by the engine to overcome the hydraulic resistance of the exhaust system in order to discharge the gases into the atmosphere. For this discussion, the exhaust back pressure is the gage pressure in the exhaust system at the outlet of the exhaust turbine in turbocharged engines or the pressure at the outlet of the exhaust manifold in naturally aspirated engines. The term back pressure can be also spelled as one word (backpressure) or using a hyphen (back-pressure).

It should be noted that the term “back pressure” is counter-intuitive and may interfere with a proper understanding of the exhaust gas flow mechanics. The word back seems to suggest a pressure that is exerted on a fluid against its direction of flow—indeed, back pressure definitions of that sort are common in sources of relaxed scientific standards. There are two reasons to object. First, pressure is a scalar quantity, not a vector quantity, and has no direction. Second, the flow of gas is driven by pressure gradient with the only possible direction of flow being that from a higher to a lower pressure. Gas cannot flow against increasing pressure—it is the engine that pumps the gas by compressing it to a sufficiently high pressure to overcome the flow obstructions in the exhaust system.

Considering how widely it is established among engine designers, we will use the term back pressure as defined above, to denote the exhaust pressure at the turbo (or exhaust manifold) outlet, which is numerically equal to the exhaust gas pressure drop over the entire exhaust system. However, we feel that the usage of this term should not be extended to denote the exhaust gas pressure drop over particular exhaust system components, as occasionally used by some authors. For instance, we avoid using the term “muffler back pressure” in favor of “muffler pressure drop” (or “pressure loss”), in accordance with the terminology used in fluid dynamics.

Common metric units of exhaust back pressure include kilopascal (kPa)—which we use in this paper—and millibar (mbar), the latter being equal to hectopascal (hPa). Common customary units include inch of water column (in H20) and inch of mercury column (in Hg). The following relationship exists between these units:

1 kPa = 10 hPa = 10 mbar = 4.0147 in H20 = 0.2953 in Hg(1)

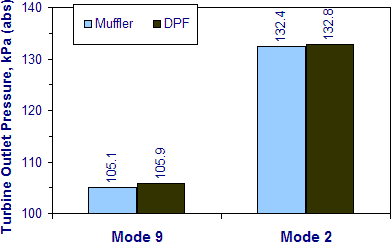

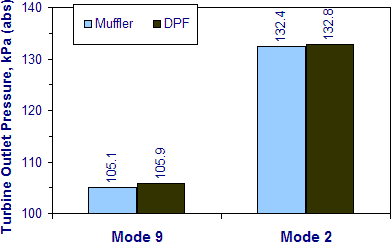

While back pressure considerations have always been faced by designers of exhaust systems, increased interest in exhaust pressure has been caused by fitting diesel engines with diesel particulate filters (DPF), and the introduction of complex aftertreatment systems in general. Installation of DPFs often raises concerns about increased exhaust back pressure. In normal circumstances, the pressure drop levels caused by an exhaust muffler and by a properly designed DPF can be actually similar. Figure 1 shows the effect of replacing the OEM muffler with a DPF on a heavy-duty diesel engine at two different modes of the ISO 8178 cycle. The change in back pressure is less than 1 kPa with a clean filter.

1997 Cummins B3.9-C EPA Tier 1 nonroad engine with muffler and retrofitted with a 6 liter DPF

However, most of the exhaust gas pressure drop over a DPF tends to be caused by the accumulated soot, rather than the filter substrate. Problems arise if regeneration of the DPF does not occur on a regular basis, causing its pressure drop to increase to unacceptable levels.

Increased exhaust pressure can have a number of effects on the diesel engine, as follows:

At increased back pressure levels, the engine has to compress the exhaust gases to a higher pressure which involves additional mechanical work and/or less energy extracted by the exhaust turbine which can affect intake manifold boost pressure. This can lead to an increase in fuel consumption, PM and CO emissions and exhaust temperature. The increased exhaust temperature can result in overheating of exhaust valves and the turbine. An increase in NOx emissions is also possible due to the increase of engine load.

Other effects on diesel combustion are possible, but depend on the type of engine. Increased back pressure may affect the performance of the turbocharger, causing changes in the air-to-fuel ratio—usually enrichment—which may be a source of emissions and engine performance problems. The magnitude of the effect depends on the type of the charge air systems. Increased exhaust pressure may also prevent some exhaust gases from leaving the cylinder (especially in naturally aspirated engines), creating an internal exhaust gas recirculation (EGR) responsible for some NOx reduction. Slight NOx reductions reported with some DPF systems, usually limited to 2-3% percent, are possibly explained by this effect.

Turbochargers typically use engine lubricating oil as their lubricating and cooling medium. Excessive exhaust pressures can increase the likelihood of failure of turbocharger seals, resulting in oil leakage into the exhaust system. In systems with catalytic DPFs or other catalysts, such oil leak can also result in the catalyst deactivation by phosphorus and/or other catalyst poisons present in the oil.

All engines have a maximum allowable engine back pressure specified by the engine manufacturer. Operating the engine at excessive back pressure might invalidate the engine warranty. To facilitate retrofitting of existing engines with DPFs, especially using passive filter systems, emission control manufacturers and engine users have been requesting that engine manufacturers increase the maximum allowed back pressure limits on their engines.

Mufflers generally result in maximum back pressures in the range of 6 kPa. In exhaust systems with a DPF, the back pressure can rise to significantly higher levels—especially if the filter is heavily loaded with soot. The Swiss VERT program determined maximum back pressure limits in order to allow DPFs to be fitted to a wide variety of equipment [1319]. Table 1 outlines the VERT recommended back pressure limits for a range of engines sizes. The exhaust pressure for large engines was limited to low values due to valve overlap and high boost pressure considerations.

| Engine Size | Back Pressure Limit |

|---|---|

| Less than 50 kW | 40 kPa |

| 50-500 kW | 20 kPa |

| 500 kW and above | 10 kPa |

Engine manufacturers are usually much more conservative on their back pressure limits. For example, diesel generator set engines from Caterpillar, Cummins, John Deere and DDC/MTU ranging in size from 15 to over 1000 kW have back pressure limits ranging from 6.7 to 10.2 kPa.

In setting back pressure limits, many factors must be taken into consideration. These include the effect on turbocharger performance, exhaust emissions, fuel consumption and exhaust temperature. The limit that a particular engine can tolerate will depend on specific design factors and making general recommendations is difficult.

###