Conference report: 3rd Conference on Sensors for Exhaust Gas Cleaning and CO2 Reduction

13 July 2016

The 3rd International Specialist Conference: SENSORS for Exhaust Gas Cleaning and CO2 Reduction—organized by SV Veranstaltungen—was held in Leipzig, Germany on June 28-30, 2016. The conference started with an introductory seminar on automotive exhaust gas sensors. The program in the following two days included 17 presentations by industry experts on various types of sensor technologies and integration with onboard diagnostics (OBD) systems. The conference program also included a trip to the Porsche plant in Leipzig that manufactures most of the 4-door Porsche models (their 2-door models are assembled in Stuttgart). Conference delegates could take a tour of the assembly line of the newly launched Panamera, the Macan, and other models.

The introductory seminar, given by Stefan Carstens [EngineSens Motorsensor], started with an overview of sensors used for engine and aftertreatment control, illustrated on the example of Mercedes-Benz light-duty diesel engines—the OM 651 and its RDE-ready successor, OM 654. The following parts of the seminar covered the principles, design and operation of several types of exhaust gas sensors, including temperature resistive probes (Pt200); NTC (negative temperature coefficient) thermistor based temperature sensors; thermocouple sensors; oxygen sensors (binary and wide-range); NOx sensors; pressure sensors for DPF monitoring; and soot sensors.

OBD and Sensor Integration. Presentations on onboard diagnostics (OBD) focused on robust malfunction detection systems to ensure emission compliance in future vehicles. The significance of robust OBD was recently demonstrated in the Volkswagen emission scandal, where OBD systems and expertise played an instrumental role in revealing the VW dual calibration strategy by US and California clean air authorities. Computers and mobility-oriented networking have brought a disruptive change to the automotive technology—vehicles are becoming ‘smart’, connected and autonomous [Matthias Weber, Roben Automotive]. These changes also require new and improved OBD architectures and comprehensive component monitoring. While smart sensors and actuators are increasingly common in OBD systems, current California OBD rules already include stricter monitoring and traceability requirements for such components—a smart sensor with more than 2 signals (e.g., temperature and pressure) or with an actuating element (other than a heater) is considered a “Diagnostic or Emission Critical ECU” and must support a software identifier and a complex checksum that must be readable by the OBD tool. In the overall vehicle diagnostic system OBD must be also integrated with cybersecurity measures (especially when remote diagnostic tools are used) and with functional safety management (FSM).

OBD systems are often a target of tampering by vehicle users who wish to remove or disable emission components [Marcel Romijn, Brace Automotive]. In the EU, a very common modification in older models of diesel engines is blocking off the EGR flow. Many earlier EOBD systems do not detect EGR blockages, and EGR block-off plates for many models are supplied by the OEMs as replacement parts. According to some estimates, as many as 50% of older diesels in the EU may have their EGR blocked. Another modification performed by some users is the removal of the diesel particulate filter. DPF delete kits—available in Europe and in the United States—include a piece of pipe to replace the DPF and an electronic circuit that simulates the DPF sensor signals for the vehicle control and OBD system. SCR removal kits for heavy-duty trucks are also commonly available in Europe (but appear to be lass common in the United States). An SCR delete/disable kit for Euro IV/V trucks without OBD costs as little as 10 euro, while systems for newer trucks with OBD can be acquired for a few hundred euro. OBD systems should be resistant to this type of illegal aftermarket products and to common sabotage methods.

Soot Sensors. Resistive, accumulating soot sensors, while in commercial use for a few years, still experience technical problems and often insufficient durability. Continental discontinued the development of their resistive soot sensor for DPF diagnostics and is now working on an electrostatic ePM particle sensor [Sebastian Reiß]. In the ePM sensor, exhaust gas is directed toward a high voltage electrode charged to 1000 V. This results in particles attaching to the electrode and receiving charge, next delivering their charge to oncoming soot particles which in turn leave their charge on grounded parts. The lost charge current from the electrode is measured and used to estimate the soot mass in the sampled exhaust gas. DPF diagnosis is based on the difference between ePM signal and model values. The sensor is not available during cold start due to dew formation.

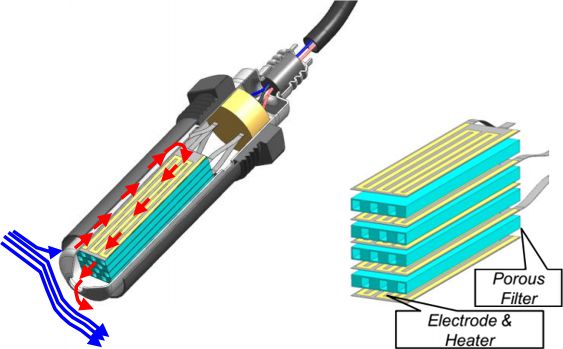

Isuzu [Sathish Vadivel] reported on the development of an accumulating soot sensor for DPF diagnostics based on the measurement of capacitance. The sensor accumulates soot in a capacitor utilizing a miniature, DPF-like structure. The measured capacitance is proportional to the soot load. The sensor is periodically regenerated using heaters that are integrated with the electrodes. The sensor still requires temperature compensation and its durability has not yet been validated.

An alternative type of a DPF leak sensor is being developed by Bosal [Robert Cloudt]. The sensor utilizes a bypass with a small detection filter and a temperature measurement—an idea originally proposed by Said Zidat. Compared to the original concept, the configuration has been changed, with the detection filter now positioned axially in the outlet pipe from the DPF. This position facilitates the regeneration of the detection filter whenever the DPF is regenerated. The remaining challenges in the development include robust, long term detection.

NOx Sensors. CPK Automotive [Frank Noack] has been developing a new NOx sensor based on the principle of an electrochemical cell with amperometric measurement. The technology, developed at the University of Dresden, utilizes gamma alumina electrolyte, placed on a heated substrate. The miniature sensor is manufactured using semiconductor technology. First laboratory and exhaust gas measurements showed promising results. The sensor can be used at temperatures up to 700°C.

The Fraunhofer Institute for Building Physics (IBP) [Judit Angster] presented their work on using photoacoustics for the measurement of various components of exhaust emissions. Photoacoustic instruments have been used for PM measurements (e.g., the AVL Micro Soot Sensor), but the method is also suitable for gas measurements. It can be used for simultaneous measurement of NO and NO2, with a sensitivity of 30 ppb NO. Photoacoustic detectors can be also used for the measurement of ammonia, with good selectivity, no water interference, and sensitivity below 1 ppmv. The method provides a quick measurement, on the order of 1 second.

Temperature Sensors. Exhaust gas temperature sensors, mostly Pt200 resistive probes, have been introduced on diesel engines around 2005, as a part of the DPF system [Frank Rothe, TT Electronics]. The number of temperature sensors has since increased, following the growing complexity of diesel aftertreatment systems and the addition of the SCR catalyst. On the other hand, the use of exhaust temperature sensors in gasoline engines has been limited, as conventional three-way catalyst systems do not require temperature measurement. However, temperature probes have been introduced on turbocharged gasoline engines for the protection of the turbocharger—TT Electronics launched their first sensor for that application in 2013. Exhaust temperature probes are also used on GDI engines fitted with NOx adsorber catalysts, and are expected to be used on GDI engines with gasoline particulate filters. In the anticipation of the growing number of gasoline applications, TT Electronics has introduced the HTS 1100 digital, high temperature probe—a type N thermocouple capable of measuring exhaust temperatures up to 1100°C.

The external shell of high temperature probes is made of nickel based alloys (Ni/Cr/Fe/Al/Y) that are used for a number of high temperature applications in automotive exhaust systems [Frank Scheide, VDM Metals]. These materials are characterized by high temperature corrosion resistance and good creep strength at temperatures above 1000°C. The applications of the VDM Alloy 602 MCA include 1100°C temperature sensors by Heraeus.

Reino Eskelinen [Reino Race Consulting] discussed an interesting test-bench development project where Pt200 temperature probes were used to measure the valve head temperature during operation of a V6 gasoline engine. The development involved hollow stem valve technology that redistributes heat from the valve, making the valve head cooler. Several designs of hollow, sodium-filled stem valves were evaluated using custom made Pt200 probes inserted into the valve stem.

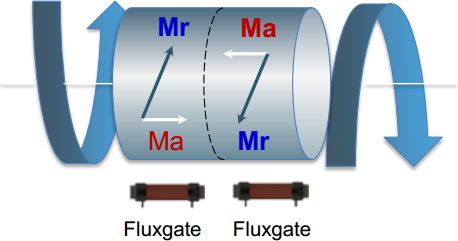

Other Sensors. A novel torque sensor based on the magnetoelastic sensing principle has been proposed [Johannes Giessibl, Methode Electronics], which can be used for a range of applications, including knock and misfire detection, engine control, and transmission control.

The measurement principle is based on the Villari effect—a change of magnetic properties of materials under mechanical stress. Upon application of torque to the shaft in the figure, the shaft magnetization (Mr) is reoriented giving rise to a magnetic field in the axial direction (Ma). This axial magnetic field is measured by magnetic sensing components (fluxgates) and processed to obtain the value of the torque as an analogue or digital signal. The sensor can be used at temperatures up to 210°C. No accuracy loss was detected after a 480,000 miles-equivalent component testing. A drawback of this method is that the component where torque is to be measured (such as a shaft) must be magnetized before it is installed in the engine.

The design and performance of a silicon-based, piezoelectric pressure sensor was discussed by Thomas Ortlepp [CiS Forschungsinstitut für Mikrosensorik]. The sensor can be used at temperatures up to 300°C, is resistant to diesel exhaust, and can be used for the measurement of pressure drop in diesel particulate filters.