ADAC releases test results of retrofit SCR systems for EU cars and LCVs

20 March 2019

Hardware retrofits of light-duty diesel vehicles, such as with SCR aftertreatment, have been considered in Europe in the aftermath of the Dieselgate emission scandal as a potential approach to reduce in-use NOx emissions from the affected cars and light commercial vehicles (LCV). Germany’s ADAC (Allgemeine Deutsche Automobil-Club) has released testing results of three Euro 5 diesel vehicles—a passenger car and two vans—retrofitted with urea (AdBlue) SCR systems.

An important purpose of the test was to determine whether the currently available retrofit SCR kits can meet the requirements of the technical regulation for diesel car retrofits adopted in January 2019 by the German Ministry of Transport (BMVI). In particular, the requirements of the BMVI regulation include:

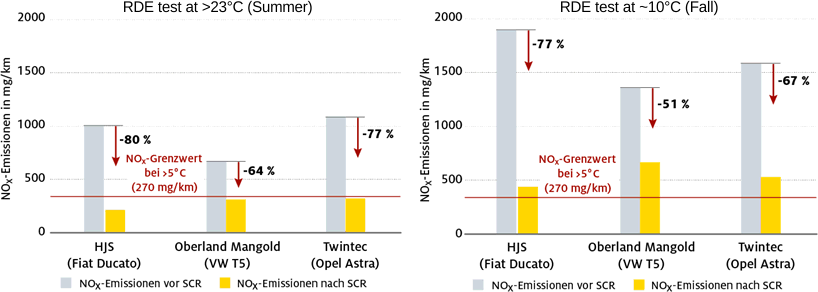

- A NOx emission limit of 270 mg/km, to be met in RDE testing at ambient temperatures from 5°C to 30°C. At lower temperatures (between 4°C and -3°C) the NOx values may be higher by a factor of 2 (i.e., 540 mg/km), at temperatures above 30°C the factor is higher at 1.6 (432 mg/km).

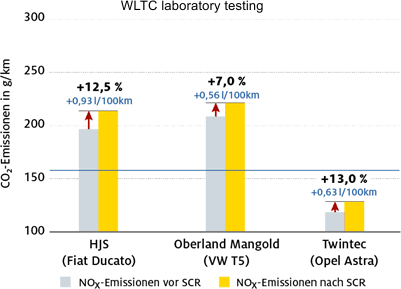

- The relative increase in fuel consumption and CO2 emissions must not exceed 6%.

- The retrofit system must have a durability of 100,000 km or five years, whichever comes first.

The vehicles in the ADAC test were driven daily for five months, until they accumulated 50,000 km. NOx emissions were tested on the road using the RDE methodology, while fuel consumption and CO2 emissions were tested under laboratory conditions. The tested vehicles were:

- Opel Astra 1.7 CDTI retrofitted with an SCR system by Twintec Baumot,

- Volkswagen T5 Multivan retrofitted by Oberland Mangold, and

- Fiat Ducato with an SCR system by HJS Emission Technology (this vehicle accumulated only 30,000 km due to an accident not related to the SCR retrofit).

Emissions. The durability test started in August, with ambient temperatures of 23°C and above. At these conditions, all three systems performed favorably, reducing NOx to below the BMVI limit of 270 mg/km. The NOx conversions in RDE testing were between 64 and 80%.

However, when ambient temperatures dropped to about 10°C in the fall, none of the systems could reduce NOx to below 270 mg/km. While the SCR NOx conversion rates, at 51% to 77%, were similar to those during summer, the engine-out NOx levels increased significantly above the summer levels. These results show that the manufacturers of the respective vehicles reduced the effectiveness of their NOx control strategies already at moderately low temperatures between 5°C and 13°C.

In winter testing, neither of the two remaining systems (Oberland Mangold and Twintec) could meet the winter NOx limit of 540 mg/km, due to the higher engine-out NOx combined with a lower conversion rates of the retrofit SCR systems, at 38% to 53%.

Emission measurements of NH3 and N2O were also conducted, showing that all systems had low emission rates for both compounds. All three SCR systems incorporated an ammonia slip catalyst.

Fuel Consumption. The tested SCR systems increased fuel consumption and CO2 emissions between 7% and 13%, which is more than the 6% BMVI limit. The fuel consumption evaluation takes place over the first three phases of the WLTC cycle, directly after the cold start—and this is where the SCR systems demanded a higher energy consumption for thermal management, to heat up the SCR system.

In addition to increased fuel consumption, the retrofitted vehicles consumed urea (AdBlue). In RDE measurements, urea consumption was between 0.7 liters (Oberland Mangold in the summer) and 3.7 liters (HJS in the fall) per 1000 kilometers.

Durability. The retrofit SCR kits experienced temporary system failures and mechanical defects on SCR components, as well as issues related to the energy supply for thermal management. The suppliers had to rectify their SCR systems several times during the test, and still have some work to do in order to be able to guarantee the durability required by the BMVI regulation, noted ADAC.

Among the three vehicles, the system supplied by HJS appeared to be most robust (however, the HJS vehicle accumulated only 30,000 km). The HJS system largely utilized series production parts from the newer, Euro 6b Ducato model.

The SCR kits from Oberland Mangold and Twintec Baumot both included urea hydrolysis reactors. These reactors were a source of significant technical issues. Also, the energy management in the Twintec system proved to be not yet mature—an additional battery in the trunk could not be reliably charged by the on-board generator under all conditions.

Despite the various difficulties, ADAC concluded that SCR retrofitting of light-duty vehicles is in principle possible—the retrofitted systems reduced NOx from the Euro 5 diesels by up to 70%, and remained effective over 50,000 kilometers.

Source: ADAC