Woodward develops high-efficiency stoichiometric natural gas combustion process

4 November 2019

Woodward has developed a natural gas fueled combustion and control strategy which achieves sub-Euro VI emissions and enables best-in-class efficiency at power densities competitive with Euro VI diesel engines. The technology, referred to as “Flame Triggered Auto-Ignition”, has been described in a technical paper presented at the recent ASME ICE Fall Conference in Chicago, IL [4542].

The technology—enabled by Woodward’s real time combustion and diagnostics system (RT-CDC)—advances gas engine combustion beyond the historical low efficiency of stoichiometric combustion to best in class efficiency, according to the company. The Woodward technology, coupled with efficient delivery and mixing of EGR, overcomes the historical knocking limitations of conventional stoichiometric gas engines and enables very short burn durations by using the controlled flame-front propagation to stage the heat release such that volumetric auto-ignition occurs during the second half of the heat release, rather than during a single heat release event usually associated with volumetric auto-ignition HCCI or RCCI combustion.

Using a three-way catalyst (TWC), emissions can be reduced to well below Euro VI levels, with a potential to meet future California NOx emission standard of 0.02 g/bhp-hr.

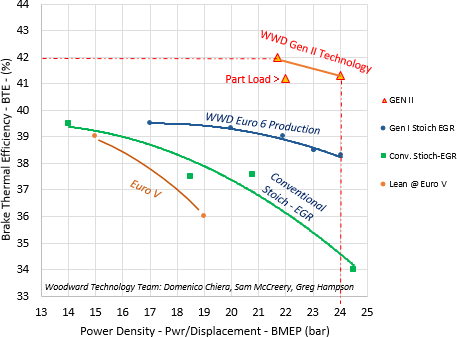

Figure 1 shows the new Woodward “Gen-II” engine results compared to other systems. While many engines report having demonstrated either high efficiency at low power density or high power density with low efficiency, the Woodward system offers high power density and high efficiency.

Woodward’s GEN II Stoichiometric-EGR-TWC system with “Flame Triggered Auto-Ignition” is shown in red with 42% BTE at 21.5 bar BMEP and 41.3% BTE at 24 bar BMEP. Competing technologies are shown: (1) Lean burn Euro V gas engines BTE-BMEP trade-off curve is shown on the lower left in brown, (2) available in production today, conventional stoich-EGR gas engine trade-off curve shown in green, (3) Woodward’s Gen I gas engine shown in blue.

A prototype natural gas GEN II engine—converted from a 15 liter, 6 cylinder, 2013 heavy-duty diesel engine—achieved 42.0% BTE at 21.5 bar BMEP and 41.3 % BTE at 24 bar BMEP, while also being able to run without power limiting knocking combustion up to 25 bar BMEP and achieving high efficiency even at part load, contributing to more than 5-10% improvement in drive cycle fuel consumption. This gas engine technology thus compares favorably with a large fraction of today’s diesel engines. Woodward’s goal is to develop this technology to achieve best-in-class gas engine efficiency and compete directly with Euro VI diesel engine systems.

Source: Woodward