Conference report: SAE Powertrains, Fuels and Lubricants Digital Summit

23 October 2020

The 2020 SAE Powertrains, Fuels and Lubricants (PFL) Conference—originally scheduled to take place in Kraków, Poland and co-organized by BOSMAL and by the Polish Scientific Society of Combustion Engines (PTNSS)—was held as a PFL Digital Summit on September 22-23, 2020. The virtual meeting included several keynote talks and about 200 technical papers on engine design, fuels, lubricants, combustion, and emissions control for light-, medium-, and heavy-duty vehicles.

Please log in to view the full version of this article (subscription required).

Future Powertrains & Fuels

A keynote talk by Stefan Pischinger of FEV considered what ICE based technologies could be used to meet various EU CO2 reduction targets. For light-duty, the hybridized ICE (gasoline or diesel) is capable of meeting the 2030 targets. Citing one example for a C-segment gasoline vehicle, a high voltage HEV with a high efficiency ICE could achieve 64 g/km CO2 (WLTP). Other options for 2030 using a diesel engine include a 48V mild hybrid with a P1 architecture or a PHEV. However, the PHEV diesel has a considerable cost penalty. Beyond 2030 to 2050, low carbon fuels would be critical for ICE-based vehicles to achieve the EU goal of carbon neutrality for on-road transport. For heavy-duty, meeting the 2025 target for long-haul transport is possible with vehicle and powertrain improvements that include 48V hybridization. However, for the 2030 CO2 target, significant fleet electrification, hydrogen fuel cells and/or policies that credit CO2 reductions from renewable fuels appear necessary. As with light-duty, low carbon fuels will be critical for ICE-based heavy-duty vehicles to meet 2050 targets. Current EU legislation is based on tailpipe CO2 emissions and thus favors electricity and hydrogen but not other low carbon fuel such as e-fuels. A well-to-wheels approach would be required to enable e-fuels to compete.

Staffan Lundgren of Volvo noted in his keynote talk that for the EU’s 2050 carbon neutrality target, the current thinking for commercial vehicles is that BEV will be primarily used for distribution, city and some regional applications while hydrogen fuel cells and ICEs with low carbon fuels will be used for long haul. While OEMs can supply the vehicles and propulsion technologies that enable carbon neutral transport, actual carbon neutrality can only be achieved if policies and the infrastructure needed to support these technologies is also in place. This component of carbon neutrality is outside the direct control of OEMs. Some important changes that would need to happen include: (1) owning and operating ZEVs would need to be a viable alternative, (2) private and public charging infrastructure needs to be deployed rapidly and (3) hydrogen production and filling stations need to be deployed.

Piotr Szymański of the JRC noted in a third keynote talk that while BEVs and PHEVs may account for up to 50% of new LDVs sold in Europe by 2030 and this may reduce oil dependency, it will increase the need for a variety of raw materials such as rare earth elements and cobalt that are needed to produce batteries. Minimizing the impact of this increased demand will require a different approach to recycling and the production-use-EoL cycle.

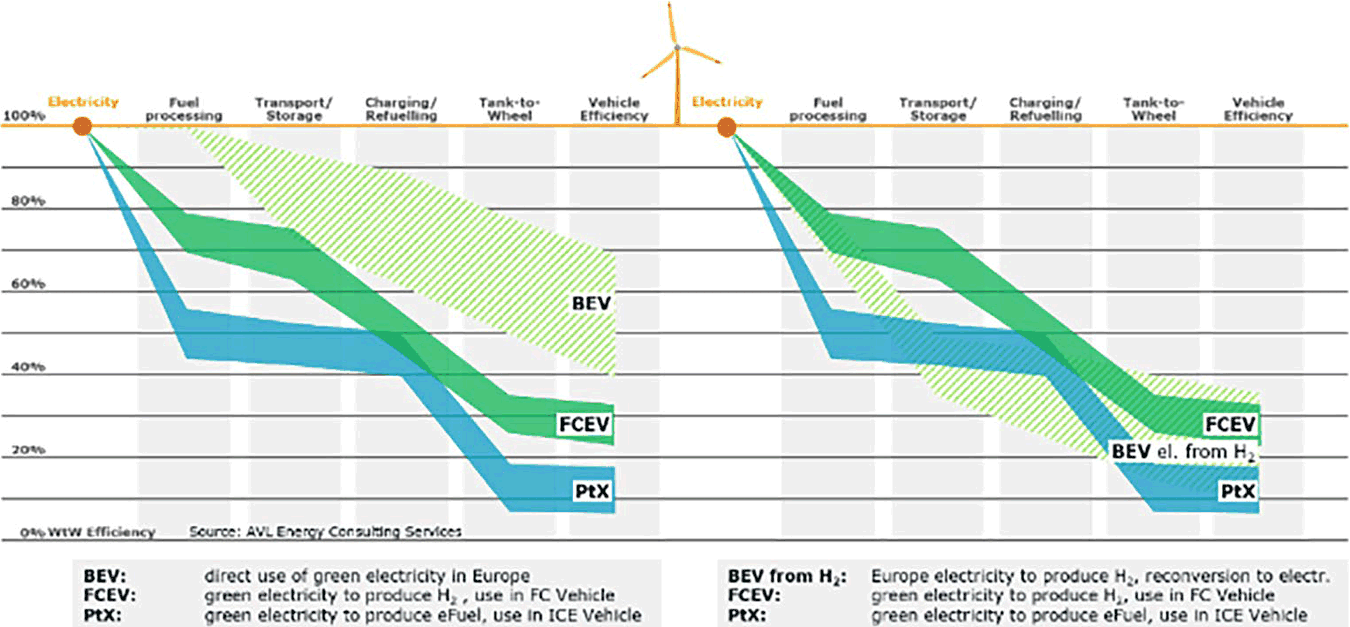

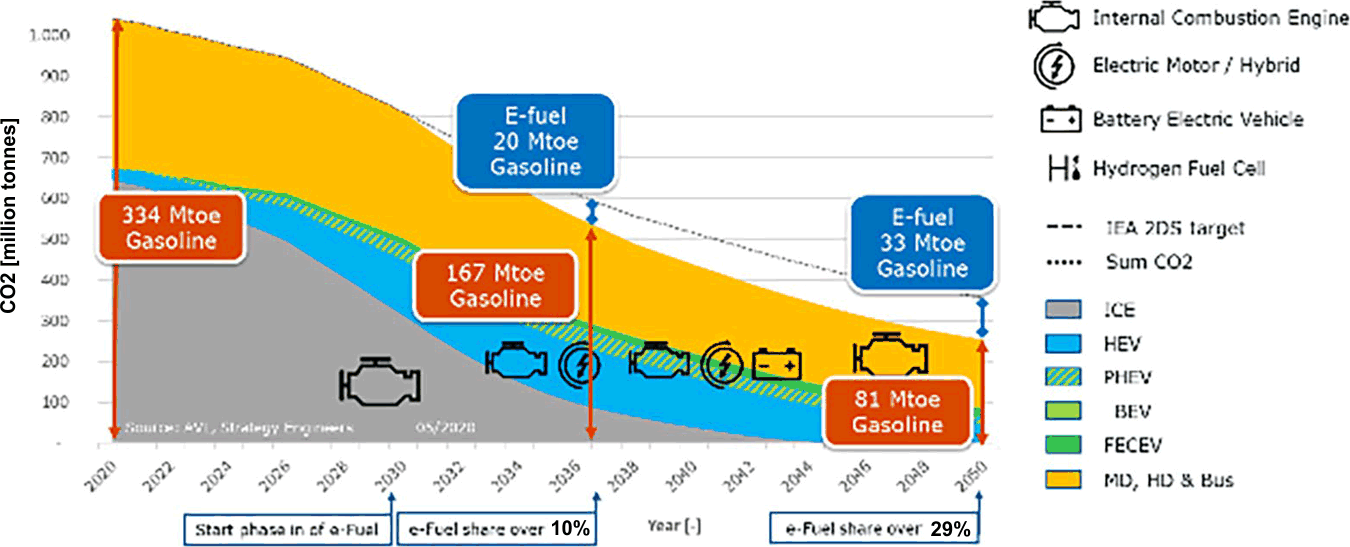

A study by AVL estimated the amount of e-fuels that would be required in Europe to meet a 2°C warming scenario by 2050 [4937]. Switching to 100% e-fuels to meet the current European on-road fuel demand (334 million t/y gasoline equivalent) is unreasonable for a number of reasons including the amount of renewable electricity that would be required—10,700 TWh or about 4 times the 2018 EU27 electricity generation. However, if a fleet mix consisting of about 2/3 BEVs and FCEVs and 1/3 PHEVs, HEVs and ICE-only vehicles is assumed (ICE-only is used mainly in heavy-duty vehicles), that allows renewable electricity to be directly used in BEVs and some proportion of the fuel demand of all other vehicles that have an ICE to be meet by e-fuels starting in about 2030, a more reasonable 33 million t of e-fuel would be required to meet the 2° warming scenario, Figure 1 and Figure 2.

Assumptions: (1) Transition to a fleet mix consisting of about 2/3 BEVs and FCEVs and 1/3 PHEVs HEVs and ICE-only vehicles; (2) e-fuels are introduced starting in 2030

In a panel discussion on fuels and lubricants, CONCAWE provided estimates that by 2050 the use of petroleum fuels for transport in the EU could be less than 10% of the current usage if carbon neutrality ambitions are to be achieved. The most likely applications that will still use petroleum are aviation and marine. Road transport would need to rely entirely on low carbon fuels. Preferably these would be biofuels derived from lignocellulosic feedstocks that do not compete with food and e-fuels produced using “green” hydrogen and CO2 using carbon capture from industrial sources and/or direct air capture. The investment required to realize these ambitions is in excess of €700 billion.

Panel discussions on powertrains covered general powertrains as well as electrified powertrains. PACCAR pointed out that total cost of ownership (TCO) and uptime are the most important factors for end users. For an on-road truck, the cost of 1 day/month of downtime can easily offset the savings from a 5% fuel economy gain. Uptime is affected not only by engine/vehicle durability but refueling time as well. Five minutes/day extra time refueling can add up to $1000/y at current driver costs.

Ricardo discussed some of the potential benefits of dedicated hybrid engines—engines designed only to be used in hybrid vehicles. This approach allows engine efficiency at a few key operating points to be optimized while controlling cost and complexity. As an example, Ricardo is developing the Magma xEV concept engine. This 3-cylinder 1.5 L DI turbocharged gasoline engine has a lightweight structure, simplified valvetrain and boosting system, no balance shaft, a long stroke and a high compression ratio. Currently it has demonstrated a 45% BTE at λ~1.7 but higher efficiencies are expected by operating at λ=2 or higher. Leaner operation will require a high energy ignition system based on corona ignition or by using an active prechamber.

Ford also stressed the importance of low carbon fuels for future ICEs, the need for future engines to handle higher thermal and mechanical loads to realize higher efficiency, the need for further developments in airpath and boosting systems and the benefits of dedicated hybrid engines. To fully exploit the benefits of alternative fuels, future engines should be designed to take advantage of unique properties of these fuels. Some examples being developed at Ford include a dedicated methane engine and a dedicated hydrogen engine. The 1.0L MTDI concept engine that is fueled by direct injected methane, has a 13:1 compression ratio, a fully variable intake valve actuation and a 2-stage turbocharging system. A hydrogen direct injection 1.0L HTDI concept engine is designed to operate ultra lean at λ>3.

Combustion

Work by Shell, PSA and others that is funded by the EU’s Horizon 2020 program is developing a Gasoline Compression Ignition (GCI) concept that works on standard European 95 RON E10 gasoline over the whole speed/load range and uses spark assist at low loads [4921]. An assessment of the efficiency of this concept demonstrated very low fuel consumption over a significant portion of the speed/load map with efficiency equivalent to that for a diesel engine. The exception is at low load where spark assist is required. Using experimental fuel consumption data for the engine, operation of a C-segment vehicle over the NEDC and WLTC was simulated. For the WLTC and RDE cycles, CO2 emissions of 125 and 118 g/km respectively were estimated. Cylinder deactivation is estimated to offset losses at low load and reduce these to 113 and 105 g/km. Aftertreatment options need further investigation.

Shell and DNV considered whether it is possible to blend components into LNG that could eliminate the need for a pilot fuel in High-Pressure Direct Injection (HPDI) Engines [4922]. They identified 65 substances that could potentially be blended into cryogenic methane and selected DME for engine testing. The results showed that while an LNG/DME blend could potentially be used to develop a mono-fuel HPDI engine, further research is needed to enable stable combustion at lower loads and idling while keeping DME proportions at levels that could be dissolved in LNG. The amount of DME needed to obtain mono-fuel operation was 7% (vol) at high load and 14% at a cruise load.

The University of Stuttgart, FKFS, Mercedes-Benz and BMW examined whether it is possible to use an outwardly opening piezo GDI injector with diesel fuel to pilot-ignite natural gas as an alternative to high energy ignition systems that would otherwise be required to ignite natural gas mixtures at high pressure [4923]. Spray chamber test results looked promising but further engine testing is needed to validate the findings. While very reproducible needle lifts are possible, the actuation of an outwardly opening piezo injector is complex, influenced by many parameters and the adjustable needle lift adds an additional degree of freedom compared to solenoid injectors.

Oak Ridge National Lab studied the knock mitigation effectiveness of EGR for SI engines [4924]. While many of the benefits of EGR are applicable to both low and high power density SI engines, including reductions in pumping work and improved specific heat ratio, the knock benefits and corresponding compression ratio increases have been limited to low power density naturally aspirated engines primarily intended for hybrid vehicle architectures. This study confirmed earlier findings that EGR is less effective at mitigating knock under boosted operating conditions relative to naturally aspirated conditions at the engine speeds investigated and with both untreated and TWC-treated EGR. While stoichiometric, boosted SI engines are unable to realize the same benefits of EGR for knock mitigation to achieve higher efficiency, the increased γ and decreased exhaust temperature can still be beneficial for efficiency. Also, under some circumstances EGR that has been treated with a TWC to remove the minor components is more effective at mitigating knock—a difference most likely attributable to NOx components but that requires further investigation.

SwRI considered the effect of changing EGR composition on SI engine combustion performance and emissions [4925]. The efficiency benefit of conventional EGR is attributed to a reduction in thermal and pumping losses, as well as a slight improvement in the γ. With CO2-only EGR (a lower γ) efficiency remained constant with increasing dilution while with conventional EGR, thermal efficiency increased by nearly 3 points at maximum dilution. With N2-only EGR, thermal efficiency was about one point better than conventional EGR at maximum dilution. With regard to mitigating high load fuel enrichment, CO2-only EGR mitigated enrichment similarly to conventional EGR. The knock performance for CO2-only EGR was better than conventional EGR, while with N2-only EGR, knock performance was nearly identical to conventional EGR. The maximum load which could be obtained at MBT timing was higher for CO2-only EGR.

Emission Aftertreatment

Future lower NOx emission standards for heavy-duty engines, such as those already legislated in California and expected at the US federal level, require a rapid heat-up of the exhaust aftertreatment system. However, as the required thermal management results in increased fuel consumption and CO2 emissions, a NOx-CO2 trade-off for cumulative cycle emissions can be observed. IAV reported [4916] on a model-based investigation of a high efficiency engine layout and optimal thermal management calibration to meet future lower NOx standards while not exceeding the CO2 limits for MY2027 vocational vehicles defined by the US GHG Phase 2 regulation. These goals were met using a high efficiency engine concept—PFP of up to 230 bar; CR of 19.5; state-of-the art TC group with total TC efficiencies of up to 60%—coupled with a dual-stage SCR system using a close-coupled SCR stage.

Soot deposited in the DPF wall pore structure causes a higher pressure drop than cake deposition. New DPF regeneration models developed at Waseda University [4917] suggest that the parameters of forced regeneration can be optimized—such as by using a higher temperature in the initial stage of active regeneration—to preserve the soot cake and prevent redeposition of soot in the pores after the regeneration, therefore minimizing the filter pressure drop.

A multi-functional fluid (MFF) intended for SCR-coated particulate filters (SCRF) was developed by IFPEN and Total [4918]. The fluid, injected into the exhaust line instead of AdBlue, consists of aqueous urea solution combined with a fuel-borne catalyst (FBC) to enhance soot oxidation. Soot loading and regeneration tests showed a beneficial effect of the MFF as a soot oxidation enhancer for both passive and active regeneration. The need for active regeneration as well as its duration were reduced, leading to reductions in fuel consumption and CO2 emissions, simulated to be between 0.5 and 2.9%. Future work will assess the impact of the MFF on DPF ash accumulation and PN emissions.

PN Emissions

The EU’s JRC evaluated the effect on >23 nm SPN (PNC23) of a method developed by the PMP group to measure sub-23 nm SPN (PNC10) and found that the different losses of the evaporation tube used in the current regulatory method and catalytic stripper in the proposed method do not result in notable differences in the total counts for PNC23 and that adding 15 nm particle count reduction factor to the calculation did not improve the accuracy for PNC23 [4926].

Additional work in conjunction with BOSMAL has similar results when >10 nm and >23nm systems were used in parallel to measure SPN emissions from more than 30 Euro 5 and Euro 6 gasoline, diesel and CNG vehicles; the difference between PNC23 for the two systems was on average 6% [4927]. However, a few exceptions were noted when there was a high release of nonvolatile sub-23 nm particles from elastomers and the catalytic stripper system measured much lower SPN. The use of elastomers should be avoided when 10 nm measurements are conducted because high exhaust gas temperatures may release material from them that could interfere with the nonvolatile measurements.

BMW and Physikalisch-Technische Bundesanstalt carried out a comparison of the counting efficiency and COV of commercial PMP system (AIP Automotive model SPC8000) and a commercial PN-PEMS (AIP Automotive PEMS-PN/GAS) using a calibration set-up based on a soot generator and high accuracy reference CPC [4928]. They found that the PMP system showed excellent repeatability of the size-dependent counting efficiency with a COV of 0.3% to 0.7% at 41, 70 and 100 nm and 1.9% 23 nm while that for the PN-PEMS was between 4% and 7% across all points—an indication of internal flow control instability likely due to compromises related to size, weight and energy consumption restrictions for the mobile application. They suggest such a calibration approach which regards the PN counting system as a “black box” would greatly simplify accreditation, metrological traceability and improve the direct correlation of different PN measurements including the new low-cost PTI systems that are emerging.

Other work related to PN emissions that was presented included a summary of the DownToTen Project [4929] as well as work related to fuel effects and lubricating oil effects. With regard to fuel effects, IFPEN confirmed that the effect of ethanol addition on PN is closely tied to the aromatics content of the fuel—no significant difference in PN emissions is observed with increased ethanol content if the aromatics level is held constant [4930]. They also noted that with the simultaneous addition of aromatics and ethanol, the PMI indices do not exhibit a good correlation with vehicle test measurements and the Smoke Point (ASTM D1322) provides a better correlation with particle number emissions. Researchers at Chalmers University of Technology had similar results with ethanol and ETBE—no reduction in SPN emissions were noted with oxygenate containing EN228-compliant gasoline fuel blends compared to one with no oxygenates—the aromatic content of the three blends ranged between 26-30% [4931]. On lubricating oil effects, Total Marketing Services and APL Automobil-Pruftechnik Landau GmbH found that for a series of 0W-12 prototype oils, PN emissions during transient operation are linked to oil formulation and that the viscosity modifier polymer has a significant impact on the PN size distribution [4932].

***

With the unknown duration of the ongoing Covid-19 crisis, the 2021 SAE PFL conference is scheduled as a virtual event for September 28-30, 2021. It is anticipated that the next live PFL meeting could be organized in 2022. The 2022 SAE PFL conference would be organized again with the support of BOSMAL and PTNSS and would take place in Kraków, Poland in September 2022.