Conference report: SAE COMVEC 2023

29 September 2023

The SAE International’s COMVEC™ Conference was held on September 19-21, 2023, in Schaumburg, Illinois, USA. COMVEC is a leading forum for the commercial vehicle industry that facilitates the exchange of information on research and technology among experts in the on-highway, off-highway and defense sectors. The COMVEC formula includes keynote speeches and panels with Q&A sessions—in contrast to other SAE conferences, there are no technical paper presentations and no conference proceedings are published. This year’s event was attended by some 650 registered participants—including many executive level attendees—mainly from North America and Europe. The conference also included an exhibition for commercial vehicle manufacturers and their suppliers.

The main focus of the event was the decarbonization of transportation and alternative powertrain technologies for heavy-duty vehicles—including battery electric vehicles (BEV), fuel cell electric vehicles (FCEV) and hydrogen combustion engines, as well as low-carbon fuels and clean combustion engines. Some of the key messages from the panel discussions on decarbonization and sustainable mobility were:

- Conventional trucks are the backbone of the economy and will continue to be very relevant in the next decades [A. Kreso, Daimler Truck]. The introduction of alternative powertrains faces several challenges: the lack of ZEV infrastructure; lack of commonality and partnership in new technology platforms such as those for charging and fueling; high cost of ZEVs; and the cost of energy including H2 and eFuels.

- Challenges to decarbonize increase with the vehicle class: cars are easy to decarbonize through electrification, medium-duty vehicles are harder, while heavy-duty trucks are the most challenging because they are already very efficient [D. Hillebrand, US DOE]. The US government objectives are to reach 60% of new zero-emission cars and 30% of zero-emission medium- and heavy-duty vehicles by 2030.

- Medium-duty BEV trucks are already in production. However, their acquisition price is 2-3 times higher than the price of a comparable diesel vehicle. A transition to low-carbon technologies would require a combination of a viable product technology, a competitive total-cost-of-ownership (TCO), and the availability of charging/fueling infrastructure [R. Aneja, Daimler].

- There is no single winning technology for future long-haul trucks. While fuel cell engines may provide a viable solution in the long term, they face technical challenges and high costs. In the medium term, H2 ICE can offer such advantages as a similar vehicle packaging to diesel and a higher payload than FCEV. Hybrid range extender systems may be adopted as a bridging technology [T. Frazier, Cummins].

- For the first time ever, the industry is faced with regulations that dictate penetration rates for new technologies, however, the industry cannot create customer demand. As the business case is not always very strong, government funding is an important enabler of low-carbon technologies. On the other hand, a change in policy or subsidy levels can rapidly change the market trends. This makes long term investment very uncertain.

- The upcoming emission standards, particularly the proposed US EPA Phase 3 (2027-2032) GHG emission regulation in conjunction with California ACT/ACF regulations and the 2027 low NOx emission standards represent a revolutionary change in regulatory requirements [M. Noonan, Navistar]. Manufacturers must choose their future vehicle technology and take billion-dollar investment decisions now, before the enabling infrastructure is put in place and without any customer/market feedback. This represents unprecedented business risk for engine and vehicle manufacturers.

- Government policies select future technologies based on tailpipe emissions alone. This is a risky approach that can be counterproductive in reducing emissions. The environmental effects of transportation and mobility technologies must be compared based on life-cycle analysis.

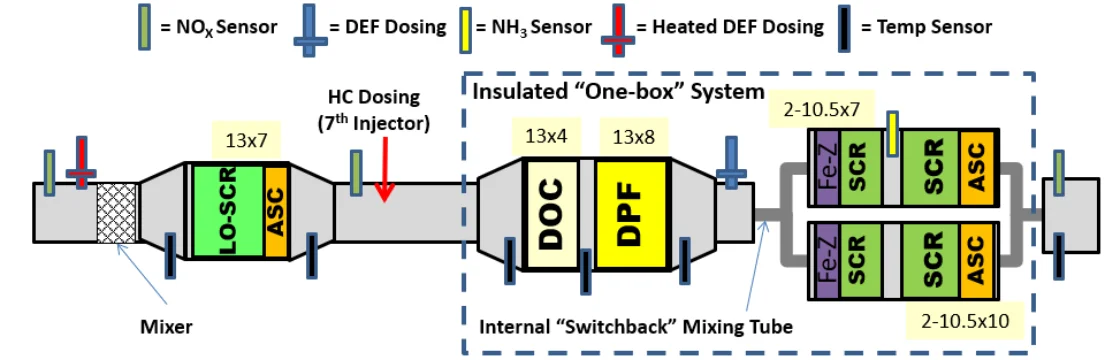

Low NOx Engines. In the session on combustion engines, the SwRI [C. Sharp] provided an update on their ongoing low NOx diesel engine demonstration. New results were presented with the most recent aftertreatment configuration (Figure 1) aged to 800,000 miles.

(Courtesy of SwRI)

Compared to the earlier configuration, the key change was a replacement of the Cu-based SCR catalyst with a hybrid, Fe-Cu SCR system. This new SCR formulation helped reduce N2O formation over the SCR catalyst, effectively removing the N2O emissions constraint. This in turn allowed more flexibility with engine calibration for low NOx, as well as a CO2 improvement due to less need for thermal management. NOx emissions at 800,000 miles were about 10-12 mg/hp-hr lower over all relevant test cycles compared to the earlier system. N2O emissions were at a half of the EPA standard.

An electric heater could be added to this aftertreatment configuration to further enhance the NOx margin and improve the overall system CO2 emissions. The use of an e-heater would be particularly compatible with hybrid powertrains, where the heater power could be supplied via battery storage from hybrid regenerative braking.

Fuel Cells. Developers of hydrogen fuel cell systems strive to achieve increased durability and robustness, with lifetime targets as ambitious as 12 years, 25,000-30,000 hours, and 1 million miles [T. Kshatriya, KPIT]. A number of challenges are related to catalyst degradation due to metal impurities and contaminants in the hydrogen fuel and air.

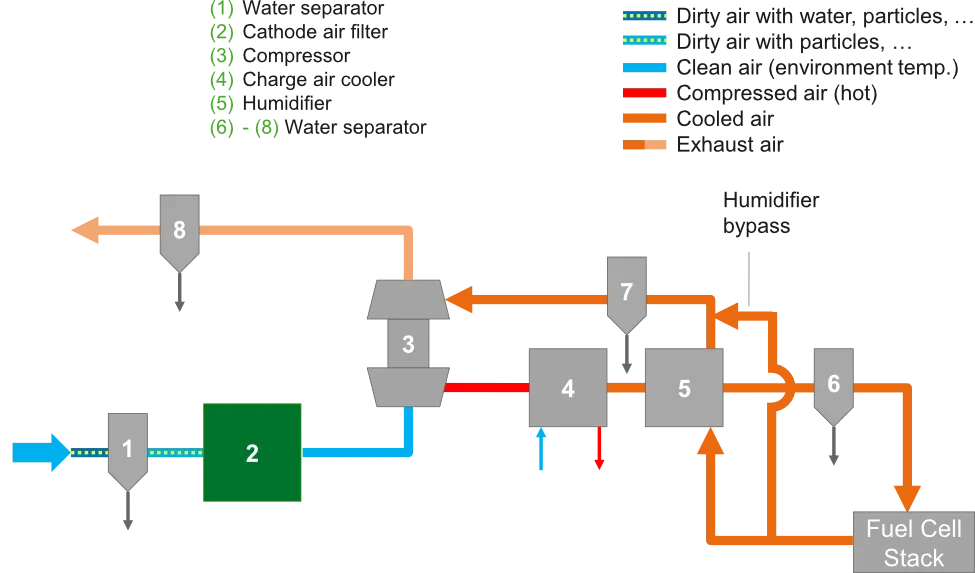

While the requirements of fuel cell engines for high purity hydrogen have been widely publicized, Mann+Hummel [M. Zerilli] showed that fuel cells are also very sensitive to deactivation by air pollutants, both particles and gases, even at low concentrations such as those found in the ambient air. For instance, contamination of cathode air with S- and N-containing gases leads to a reduction of the platinum catalyst electrochemically active surface area, while humidifier membranes are sensitive to ammonia exposure. Therefore, fuel cells require filtration and conditioning systems for the cathode air, Figure 2.

(Courtesy of Mann+Hummel)

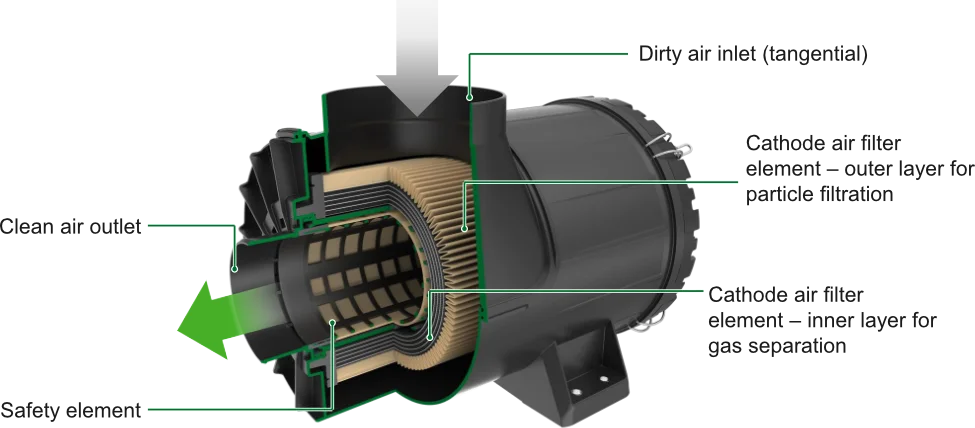

Figure 3 shows an example design of a cathode air filter. The outer pleated media layer filters particulate pollutants, while the inner layers can provide various forms of gas separation functionality. The main gas purification mechanism is adsorption by activated carbon. Gas capture can also be augmented by impregnation to facilitate chemical adsorption. Further chemical impregnation with a catalyst can be used to promote catalytic conversion of pollutants.

(Courtesy of Mann+Hummel)

EV Battery Safety. One entire session was devoted to EV battery failures, with a focus on battery fire. While EV fires are not necessarily more common than fires in gasoline vehicles, battery fires are much more difficult to extinguish and a large proportion (~40%) of fire incidents occurs with the vehicle off and in park.

The panelists discussed such topics as explosion control in battery energy storage systems (BESS), battery abuse testing, and model development to understand battery failure [A. Mallarapu, NREL]. Thermal safety of EV batteries is subject to new standards and regulations. Chinese standards (GRTR20, GB38031) specify a period of 5 minutes between the warning of thermal runaway and the safe escape of passengers [A. Dendrinos, AVL]. The global EV market trends are toward “no thermal propagation” products.

* * *

Next year, COMVEC will return to Schaumburg, Illinois—the event is scheduled for September 10-12, 2024.

Conference website: comvec.sae.org