WinGD and CMA CGM collaborate to trial VCR technology at sea

13 August 2024

WinGD announced its Variable Compression Ratio (VCR) technology is to be trialed by global shipping line CMA CGM onboard one of the company’s vessels. The collaboration marks the first field test for the new dual-fuel engine technology and follows factory tests showing significant efficiency improvements with both diesel and LNG fuel, the company said.

VCR dynamically adapts cylinder compression ratio in X‑DF dual-fuel engines according to the fuel selection, ambient conditions and engine load, reducing fuel consumption. The CMA CGM trial marks the first use of adjustable compression ratio—normally a fixed design parameter—in any marine engine, according to WinGD.

The CMA CGM project comprises a long-term, full-scale test to confirm operability and reliability. Onboard testing is expected to begin following the dry-docking of the vessel in September, when VCR will be installed on the vessel’s WinGD RT flex50DF dual-fuel engine.

(Source: WinGD)

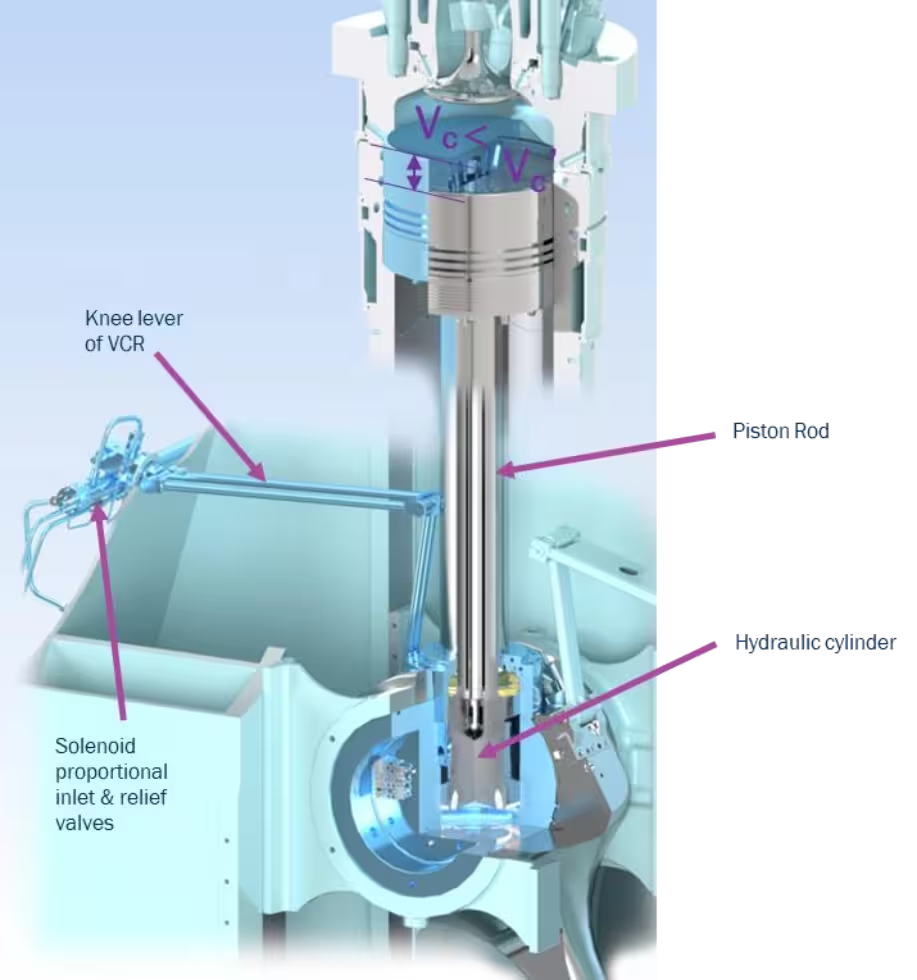

The VCR mechanism adjusts the compression ratio (CR) continuously by varying the compression volume (Vc). This is achieved by moving the piston rod in vertical direction using a hydraulic cylinder located in the crosshead pin. The piston position is controlled by the amount of lubricating oil in the lower chamber located below the piston rod.

The VCR technology was jointly developed by WinGD and Mitsui E&S DU Co (MESDU) (formerly Diesel United and then IHI). Last year, WinGD announced the commercial launch of the technology on low-pressure LNG fueled X-DF engines with 72 cm and 62 cm bores [5901].

Japan’s NYK Line said it would install the VCR system on two large LNG-fueled coal carriers to be built at Oshima Shipbuilding. The vessels are scheduled to be delivered by the end of 2025. In trials on a 6X72DF test engine at MESDU’s facilities in Japan, VCR reduced fuel consumption by 6% when running in diesel mode and by 3% when using LNG.

Source: WinGD