Conference report: US DOE 2021 Annual Merit Review

27 July 2021

The US Department of Energy (DOE) Vehicle Technologies Office (VTO) 2021 Annual Merit Review (AMR) was held as a live virtual event on June 21-24, 2021. At the AMR meeting(s), advanced technology development projects funded by the DOE are presented and reviewed for their merit. Presentations are available for download from the VTO as bulk downloads or individual presentations.

Please log in to view the full version of this article (subscription required).

SuperTruck 2

SuperTruck 2 is nearing completion with most teams expecting final demonstrations to be completed between year end 2021 and mid-2022. PACCAR, which started after the other four projects, expects to complete their work by fall 2022. Cummins has already demonstrated 55% BTE for their diesel engine in January of this year.

For Daimler [5170], the phase change cooling (PCC) system has been put “on hold” and the final demonstration will be done with a more conventional WHR system using exhaust and EGR heat. Technical challenges due to manufacturing were cited as the reason for not proceeding further with the phase change cooling system. The PCC was expected to increase BTE by 3.6% while the cyclopentane WHR system provides a 2.5% improvement. Daimler feels confident they will still hit the 55% BTE target with the cyclopentane WHR system due to synergies once all improvements are tested together. The benefit from thermal barrier coatings applied to the head and piston are still expected to be around 0.8% based on the BSFC reduction shown in single cylinder experiments. Simulations predicted the friction reduction package to yield 0.5% BSFC improvement. The 55% BTE engine demonstration is expected in Q3 2021. Their stretch freight efficiency target is 125% improvement over a baseline 2009 truck and they are expecting to achieve 128%. The freight efficiency demonstration is expected Q4 2021. Some freight efficiency features include an active trailer gap, adaptive trailer ride height, dynamic load shift on the tractor’s rear axles and an adaptive tandem axle. The 48 V hybrid system recovers 10 to 15 kWh, depending on traffic, over one of their test routes. The freight efficiency vehicle will use a 13 L engine but without some of the additional technologies, such as WHR and thermal barrier coatings, used in the 55% BTE engine.

Volvo’s 13 L for the 55% BTE demonstration is based on a US 2024 engine with 47.5% BTE [5171]. The baseline engine already uses low friction rings, improved bearings and a variable oil pump. To achieve 55% BTE, compression ratio will increase to 23:1, peak cylinder pressure capability to 250 bar, the WAVE piston will be coated with a thermal barrier coating and Miller intake valve timing will be used. Parasitic losses will be reduced with electric EGR and coolant pumps. For the dual loop WHR system, the tailpipe WHR system will be tested later this year while testing of the coolant WHR will be carried out in early 2022. Estimated gains are 2% BTE from exhaust and 1% BTE from coolant heat recovery.

Cummins Peterbilt completed their 55% BTE engine demonstration in January 2021 [5172]. Waste heat recovery provides a 4.4% BTE improvement with their dual loop WHR system having a low pressure loop (LPL) and a high pressure loop (HPL) for low and high temperature waste heat sources respectively. Heat recovery is from the EGR systems, exhaust, charge air and engine coolant. The final demonstration required a second tailpipe boiler incorporated into the LPL. The freight efficiency demonstrator will use the 55% BTE engine and they expect a 170% improvement over the 2009 baseline to be demonstrated by mid-2022. Some vehicle technologies include: a hybrid steel/aluminum chassis, adjustable tractor ride height, engine-off coasting (enabled by the 48 V system), a disengageable 2nd drive axle, a dynamic sleeper extender and a lightweight aerodynamic trailer.

Navistar is evaluating combustion system options for their 55% BTE engine with final piston bowl selection and evaluation still to be carried out [5173]. The WHR system has demonstrated a 3.0% BTE contribution. Further refinement to lower restrictions and match the expanders is required. The aftertreatment system will use a dual dosing SCR system with an electric heater to achieve rapid light-off of the downstream SCR catalyst and heated urea dosing. Aftertreatment system durability and fuel penalty have not been determined. Their stretch goal of 140% freight efficiency improvement relies heavily on weight reduction and hybridization.

PACCAR’s 55% BTE engine with a dual loop WHR system and Cummins’ dual entry turbine with a mechanical connection to the drivetrain [5174]. The LPL of the WHR system recovers heat from the coolant, oil and both high and low pressure charge air coolers (dual-core two-stage charge coolers that include an additional chilled water loop). The HPL is connected to a dual-core tailpipe boiler. A 4% BTE improvement is still expected from the WHR system. The aftertreatment system includes a 48V electric heater and targets CARB 2027 ultra-low NOx limits. For the vehicle, a 175% increase in freight efficiency is expected.

Engines

In a project that started in October 2020, Wabtec is partnering with Sandia and SwRI to investigate ducted fuel injection (DFI) and “cooled spray” (CS) technologies for controlling particulate emissions from nonroad heavy-duty diesel engines [5175]. Cooled spray technology uses a monolithic insert with multiple fuel and air passages installed in the cylinder head that mounts over the fuel injector nozzle. Details of DFI are well known. DFI has demonstrated nearly sootless combustion while cooled spray as shown >70% PM reduction at full load. The program aims to achieve a 75% PM reduction over the operating range using CS technology and to develop scaling rules to apply DFI and CS to small and large engines. Evaluations will be carried out in high speed single cylinder engines with DFI evaluated in Sandia’s optical engine (125 mm bore/1.72 L) and CS in a metal engine (168 mm bore/4.4 L) at SwRI.

University of Wisconsin with Purdue University and John Deere are demonstrating how electrification could be used to improve efficiency for nonroad applications [5176]. Their approach is to replace a 6.8 L with a 4.5 L engine and use an eBooster (electrically driven compressor) and hybridization to ensure machine performance is not compromised. Without an optimized calibration, the 4.5 L engine with eBooster is expected to decrease BSFC by 8.6% over the NRTC due to improved mechanical efficiency. With an optimized calibration (increased EGR and advanced SOI enabled by improved AFR control with the eBooster), BSFC can be reduced by an additional 9% due to higher gross indicated efficiency (GIE) at equal NOx levels. Once incorporated into a nonroad vehicle, further efficiency improvements are expected via energy recovery. The electrified drivetrain will operate at 700 VDC and will include energy storage with a battery or ultra-capacitor.

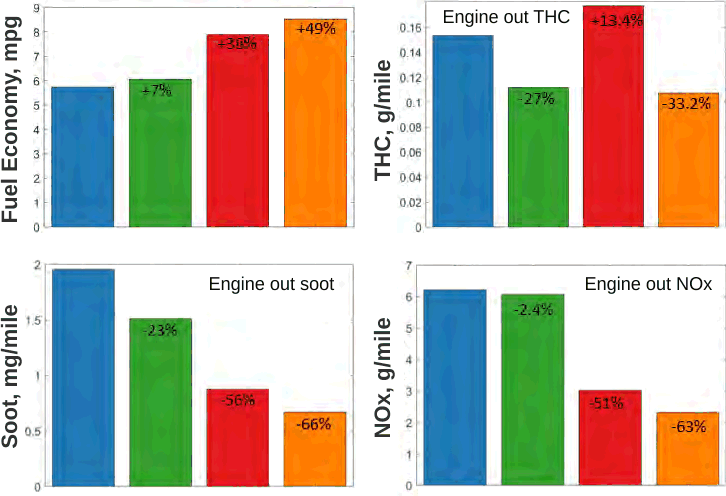

Oak Ridge and Cummins are collaborating on a project that includes a portfolio of tasks intended to provide data for improving predictive models and future engine designs for conventional and electrified medium- and heavy-duty truck powertrains [5177]. The tasks include developing an optical probe to measure in-cylinder surface temperatures, developing the capability to image difficult to access components such as the fuel injector with neutron imaging, further development of gasoline compression ignition (GCI) and addressing the challenges of cold-start/restart for electrified powertrains. For the GCI work, a heavy fuel stratification (HFS) injection strategy offers diesel-like control authority over combustion phasing with low smoke and high combustion efficiency and is able to overcome low load stability challenges—even at the 50% EGR levels required for low temperature combustion. In the cold-start/restart work, hybridization and start/stop can still offer significant fuel economy NOx and soot benefits even after applying increased levels of thermal management required to ensure the SCR catalyst remains active, Figure 1.

Blue = conventional mode, green = conventional + start/stop, red = hybrid mode, orange = hybrid + start/stop.

Hybrid details: connected via a power takeoff (PTO) unit on the transmission and includes a Remy HVH250 electric motor with a rated power of 70 kW, a Sevcon inverter, and dual Johnson Controls-Saft (JCS) battery packs with a total capacity of 28.8 kW-hr [5167].

Aftertreatment

Aftertreatment technologies continue to be an important focus of DOE research. Some of the technologies discussed included passive NOx adsorbers (PNA), SCR catalysts and three-way catalysts (TWC).

PNA

Research on PNAs included the effect of substituting Cu, Ag or Co for some of the Pd [5182]. One of the more promising candidates was Cu. With a ratio of Cu:Pd = 1:1, NO uptake relative to the Pd content improved significantly. Compared to Pd-only, a similar uptake of NO was achieved while only using half the Pd. However, Cu did nothing to improve stability—degradation over time was similar. As a result of the poor stability of the NO adsorption capacity of current PNA materials, Oak Ridge is ending its CLEERS research into passive NOx adsorbers and publishing results [5188]. Future PNA work is contingent upon discovery of a PNA material with stable adsorption capacity.

SCR

While the low temperature stability issues of SAPO-34 SCR catalysts are well known, work at PNNL continues as there is still interest in its application due to its lower cost [5183]. It is believed that the low temperature stability issues can be mitigated, for example by optimizing catalyst compositions or by catalyst pretreatment strategies such as saturation with ammonia [4130].

As noted last year, researchers at PNNL and Cummins showed that field aging of SCR catalysts is not replicated by hydrothermal aging (HTA) in the lab. While including sulfur exposure during HTA accelerated the aging of Cu-SSZ-13, the effect was still not sufficient to explain the loss of SCR activity of field aged samples [5184].

Work on a passive SCR system by Oak Ridge, GM and Umicore continues [5185]. Engine testing demonstrating an efficiency benefit while achieving Tier 3 Bin 30 emissions using less than 4 g Pt-equivalent/L engine displacement is being carried out with a lean burn gasoline engine based on a 2.3 L Ford Ecoboost engine fitted with MAHLE Jet Ignition (MJI) over a transient drive cycle. To-date, an 8.3% fuel economy benefit relative to stoichiometric operation has been demonstrated. An expanded lean operation map with MJI is expected to enable an even larger benefit with results expected in Q4 2021/Q1 2022. Evaluation of several SCR catalysts showed that commercial diesel SCR catalysts are still active even after rich aging at 800°C with synthetic exhaust. The latest Gen 4 SCR catalyst showed some degradation of high temperature NOx conversion above 350°C but was still able to maintain low temperature NOx conversion. Aging of the SCR catalyst under passive SCR conditions is planned.