Conference report: 2021 CLEERS Virtual Workshop

29 September 2021

The 2021 CLEERS Workshop was held as a virtual event on September 13-17, 2021. CLEERS—Crosscut Lean Exhaust Emissions Reduction Simulations—is an initiative funded by the US Department of Energy (DOE) to support the development of computer simulation tools for engine emission control systems. The workshop included 37 technical presentations, a panel discussion, and poster sessions. The topics covered diesel aftertreatment systems for meeting ultra low NOx emissions, novel catalyst preparation technologies, three-way catalysts, particle filters, SCR catalysts, and passive NOx adsorbers (PNA).

Please log in to view the full version of this article (subscription required).

Low NOx HD Diesel Engines

The workshop opened with an invited presentation by Chris Sharp [SwRI], who talked about the ongoing demonstration efforts towards the California 2027 low NOx targets for heavy-duty engines. The program was started in 2014, and three CARB-funded stages have been completed. The current development effort is funded by the US EPA. The SwRI has also been developing a nonroad version of the low NOx engine, towards a potential Tier 5 nonroad emission regulation.

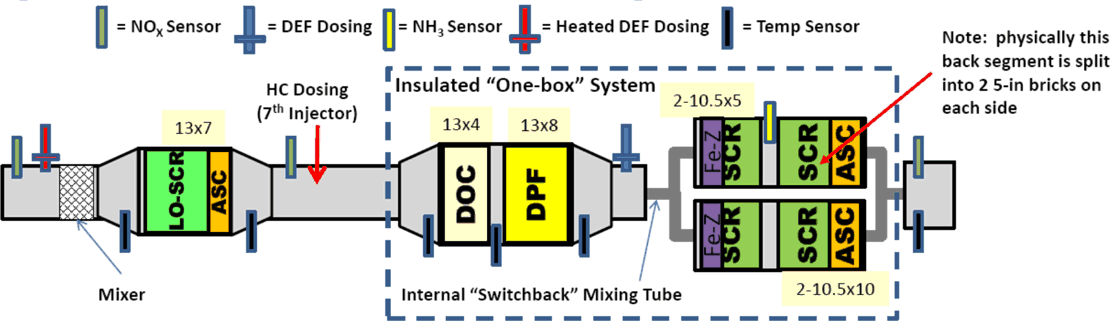

The starting point for the current stage of the development has been a 2017 Cummins X15 engine with a modified calibration and hardware, including a cylinder deactivation kit from Eaton. The changes have been introduced to enable a thermal management strategy to increase exhaust gas temperature and reduce NOx when the engine is cold, while minimizing the impact on CO2 emissions. The current version of the aftertreatment system is shown in the following schematic. A sophisticated model-based aftertreatment control has been developed that utilizes three electronic ‘NH3 observer’ modules, one for each of the SCR catalysts.

The changes to the aftertreatment in the latest version of the system include (1) replacement of a zone-catalyzed DPF with a DOC + DPF to improve durability, (2) improved mixing to reduce SCR bank-to-bank deviations, and (3) addition of an Fe-Z catalyst in front of the SCR to reduce N2O emissions. The emission system was aged over an accelerated aging cycle to 435,000 miles, with exposure to oil, sulfur, and chemicals (ash). The engine was tested over a number of test cycles, including real world cycles that were transformed into laboratory tests.

The engine produced 0.020 g/bhp-hr NOx over the composite FTP cycle—a value equal to the applicable standard, but still without an engineering margin—and satisfied the NOx standards over several other cycles. The NOx conversion was 97.8% - 99.6%, depending on the cycle. CO2 emissions were generally neutral over several test cycles, with the exception of the LLC test, where CO2 increased by some 1% - 1.3%. In use compliance results, determined by the moving average window methodology, were acceptable for the 2027 requirements, but fell short of meeting the 2030 CARB standards. Overall, these results can be described as partially successful—in spite of the significant effort and state-of-the-art R&D resources, the demonstration has not yet produced an engine that could be certified to the 2027 CARB standards. The results of the program will inform the ongoing development of the federal version of the low NOx regulation by the US EPA.

Future plans include testing of the Stage 3 system aged to 600,000 and 800,000 miles. In parallel, a simplified ‘EPA Team B’ configuration has been developed of smaller space requirements, using smaller catalysts and a post-injection based DPF regeneration. While preliminary NOx conversion results have been promising, the EPA Team B system had a higher pressure drop, 40 kPa vs 28 kPa in the Stage 3 system, and a 1.5% CO2 penalty over the RMC cycle.

A similar aftertreatment approach with a two-stage SCR system was developed by AVL [J. Kasab] for Euro VII and for CARB 2027 truck applications. To meet the more stringent Euro VII limits that are being considered (CLOVE HD3: 175/90 mg/kWh NOx in cold/hot conditions), the system also included an electrically heated catalyst (EHC) upstream of the close-coupled SCR. Installed on a demonstrator truck, the system with the EHC achieved 18 mg/bhp-hr NOx, however, N2O emissions and future OBD/OBM requirements remain a challenge. Vanadium based SCR catalyst is preferred—it does not require a close-coupled DOC, resulting in a lower thermal mass—but vanadium is unlikely to be accepted for US EPA/CARB applications.

Under the CARB low NOx regulation, the full useful life (FUL) period for heavy heavy-duty engines has been almost doubled, from the current 435,000 miles to 800,000 miles. Meeting the increased emission durability requirements would require diesel catalysts of increased durability, which are not yet commercially available, and no significant improvement in catalyst technology has yet been shown to enable such an increase of FUL. A panel discussion was held on catalyst durability, with the participation of Tom Pauly (Umicore), Danan Dou, (John Deere), Alissa Recker (Daimler), and Christine Lambert (Ford). The key issues and information gaps that were identified include accelerated catalyst aging protocols that can accurately mimic hydrothermal and chemical (sulfur & lubricating oil) impacts; durability/poisoning effects of charge air impurities (particularly in certain nonroad applications), water condensation, urea and its deposits; lack of aging experience with close-coupled SCR and/or with high performing (>99% NOx conversion) systems; and unknown effects of supplemental heating on catalyst conversion and durability.

Novel Catalyst Concepts

A number of talks covered various basic research topics in emission control catalysts, with a focus on lowering the catalyst light-off temperature, improved durability, as well as on better utilization of platinum group metals (PGM). A light-off temperature target known as the “DOE 150°C challenge” calls for a 90% conversion of NOx/CO/HC by 150°C. The PGM utilization objective reflects the growing concern with PGM resource constraints, particularly with the prohibitively high prices of rhodium, as well as palladium.

The PGM utilization in today’s emission control catalysts is low, and most of the PGM loading in commercial catalyst formulations is necessary to ensure the required durability as the catalyst sinters. Precious metals such as Pd/Rh in a TWC are highly dispersed in a fresh catalyst, but after 150,000 miles of aging PGM particle sizes grow to 50-100 nm. As a result, less than 2% of the PGMs remain active in aged catalysts [H. Pham].

Highly dispersed ‘single atom catalysts’ (SAC), where the catalytic sites are composed of single PGM atoms or small, nanosized clusters, are being developed to improve catalyst light-off performance. New catalyst structures such as ‘core and shell’ concepts or the application of SACs onto ‘nanosheets’ of refractory oxides have been proposed to stabilize the catalysts. Many promising results were presented, but as surface stabilization and durability problems persist—particularly under hydrothermal and/or redox aging conditions—these novel concepts still play a very limited role in commercial catalyst technology.

Washington State University [D. Jiang] reported on the development of single atom Pt1/CeO2 catalysts for CO oxidation. Two catalyst preparation methods were used: (1) atom trapping (AT), where a Pt/Al2O3 catalyst is exposed to a temperature of 800°C, which causes PtO2 species to become volatile, transported onto ceria, and trapped as Pt1/CeO2; and (2) thermal shock synthesis (TS), where the ceria surface and the Pt1 configuration become reconstructed using high temperature (> 1200°C) shockwaves. The Pt1_TS species showed greatly superior low temperature activity for CO oxidation, compared to Pt1_AT.

University of Central Florida [F. Liu] proposed a support surface modification technique to obtain an active and stable oxidation catalyst. The objective of the study was to reduce the amount of ceria on alumina. The catalyst washcoat was prepared in three steps: loading a part of the CeO2 onto Al2O3, high temperature calcination, and impregnation of the remaining ceria. This produced small, nanosized ceria particles on the alumina surface. A Pt catalyst was then impregnated onto this washcoat, and activated at 400°C in hydrogen. The catalyst showed a superior CO oxidation activity compared to a reference catalyst, both fresh and after aging.

University at Buffalo [E. Kyriakidou] discussed two novel catalyst concepts: a structured DOC, and a Rh-free TWC. The DOC utilized a Pd/Pt catalyst on a structured washcoat composed of SiO2 core particles covered with an external Zr shell. An improved SiO2 surface area was attributed to the Zr shell. The Rh-free TWC utilized the Pt-CeO2-Al2O3 system, where the ceria particles were incorporated onto Al2O3 nanosheets to slow down CeO2 and Pt sintering (Pt detaching from ceria).

University of New Mexico [H. Pham] tested a series of ceria/alumina supports containing 8% to 50% ceria (CA08 - CA50), developed by BASF. Previous studies have shown that pure ceria was effective in atom trapping of Pt (up to 3% wt Pt) and maintained Pt dispersion. The new CA50 support was found to be almost as effective for Pt atom trapping as pure ceria. However, CO reduction caused growth of Pt1 into Pt nanoparticles. The new materials have not yet been tested in the presence of water, sulfur, or poisons.

Passive NOx Adsorbers

PNNL [J. Szanyi] studied the use of single Ru atom doped ceria as a passive and reactive NOx adsorber. The Ru/CeO2 material prepared by Ru atom trapping was hydrothermally stable, cost effective, and could trap NOx via two mechanisms—passive adsorption on Ru and reactive uptake on Ce as nitrites or nitrates. However, the performance of Ru/CeO2 deteriorated under rich conditions, and sulfur poisoning caused a 25% decrease in NOx storage.

A study by the Oak Ridge National Laboratory [P. Kunal] looked into Pd-dilution approaches for passive NOx adsorbers. The dilution of PGMs with less expensive metals has been pursued as a prospective method to lower catalyst costs. The other metal(s) may also enhance the catalyst performance through various synergistic effects. In the study, PdCu/SSZ-13, PdAg/SSZ-13, and PdCo/SSZ-13 systems were investigated, and compared with the Pd/SSZ-13 passive NOx adsorber. The new materials were characterized using analytic techniques such as DRIFTS, TEM, and XRD.

Particulate Filters

NGK [Z. Wang] discussed particulate filter design trends to meet future PM and PN emission standards. Current DPF substrates can meet present and future PM standards with good engineering margin. “Advanced” DPF substrates of smaller mean pore size (MPS) can additionally help reduce the DPF pressure drop while meeting future PM requirements. High ash capacity is desired to meet future extended emission useful life requirements. New filter materials will be necessary to meet the anticipated Euro 7/VII PM/PN emission standards. Thicker wall filters have higher PN efficiency, at the expense of a higher pressure drop. The same PN performance improvement may be possible using filters of conventional wall thickness, but higher porosity and smaller MPS. Interesting data was also presented on the impact of soot loading before the cycle on brake-specific PN emissions.

Diesel particulate filters are usually accompanied by an upstream DOC. However, if the DOC can be zone-coated over the front section of the DPF and still provide adequate emission performance, a simpler aftertreatment system can be used, with a reduced thermal mass upstream of the SCR catalyst. Such configuration, dubbed as diesel oxidation catalyst filter (DOCF), was examined by PNNL [K. Rappe] and John Deere. The system was evaluated using an Exothermia model assembled to match John Deere engine data with an ash-aged DOCF device. A number of results were provided on the effect of the inlet DOC zone length, and on the DPF permeability. Due to the higher washcoat load, the permeability of the front zone of the filter was reduced. With no soot, more flow was pushed through the back of the filter, which affected the HC and CO performance. With soot in the filter, on the other hand, there was no effect on performance, because more soot was deposited in the rear of the filter, with a normalizing effect on the gas flow.

Johnson Matthey [T. Watling] presented a comprehensive overview, with a historical background, of models to predict pressure drop in diesel particulate filters.

* * *

The 2022 CLEERS Workshop is planned for August 30 - September 1, 2022.