Conference report: SAE WCX 2025 Congress

25 April 2025

The SAE WCX Congress was held on April 8-10, 2025, in Detroit, Michigan. The technical program included seventeen panel discussions, 495 published technical papers, and about 200 oral-only presentations covering all areas of automotive technology. The Congress also included an exhibition, keynotes by industry speakers, and other special events. There were about 4,800 registered participants, however, the actual attendance was lower as hundreds of international participants did not show up due to concerns about travel into the United States. The following summary covers two topical areas at the Congress: Sustainability & Emissions and Advanced Powertrain.

Please log in to view the full version of this article (subscription required).

Regulatory Trends

The US Environmental Protection Agency (EPA) has announced a ‘historic’ rollback of air emissions regulations affecting all GHG emission regulations, certain emission standards for criteria pollutants, as well as certain emission waivers granted to California. While this topic was discussed at WCX, the ultimate scope of deregulation is still uncertain—it will emerge over time through a process of political and legal wrangling.

In the EU, the European Commission released the Industrial Action Plan for the automotive sector [D. Bosteels, AECC]. While the Plan maintains the long-term focus on low-carbon mobility, the Commission has proposed a flexibility for meeting CO2 emission standards for cars and vans, where compliance with the 2025, 2026 and 2027 emission targets would be assessed by averaging the performance over the entire three-year period, rather than annually. The regulatory review of the 2035 CO2 emission target—a 100% emission reduction, a.k.a. a ban on combustion engine vehicles—has been pulled forward from 2026 to Q3/Q4 2025.

In the nonroad sector, the California Air Resources Board (CARB) has started the development of Tier 5 emission standards for nonroad engines and released a draft Tier 5 proposal. The last Tier 5 workshop was held in October 2024. No future activities are currently listed on the CARB Tier 5 website. In Europe, the EU Commission will review the current Stage V emission standards for mobile nonroad machinery this year, based on PEMS monitoring data. This review may potentially lead to the development of Stage VI emission regulation for nonroad engines.

Regardless of the ongoing policy support, the uptake of battery electric vehicles (BEV) has been slowing down. According to opinions expressed in the panel discussion on electric powertrains, the market share of BEVs may flatten somewhere between 20% and 35%. While the share of conventional gasoline and diesel vehicles is expected to decline, the future vehicle mix is predicted to include a range of hybrid powertrains, from mild- and full-hybrids (HEV) to plugin-hybrids (PHEV) and range-extended electric vehicles (REEV)—all equipped with combustion engines.

Life cycle analyses (LCA) have consistently shown that BEVs are not necessarily the most effective option to reduce emissions—a message that seems to be ignored by GHG policies and regulations that consider electric vehicles to be “zero emission” vehicles. In reality, CO2 emissions from BEV manufacturing are offset by their lower in-use emissions only after a certain period of operation, which can be quite long depending on the electrical grid mix and other assumptions (such as marginal vs. average grid emissions), Figure 1. Hybridization, while effective in reducing emissions, is also the best option for customers—it avoids range anxiety issues and does not require electric charging infrastructure [A. Kulzer, FKFS Stuttgart].

Based on WLTP test cycle. Elektro 62/82 = BEV with a 62/82 kWh battery. Benzin = gasoline. Results for plug-in electric vehicles based on marginal (Ma, solid lines) and average (Mi, dashed lines) grid emissions. Germany’s electrical grid mix.

(Source: VDI)

Advanced, efficient powertrains can be combined with the use of low carbon fuels. An LCA study by Toyota and Chevron evaluated several prototype renewable gasoline blends that had at least 40% lower carbon intensity compared to commercially available E10 gasoline. The fuels were evaluated in a naturally aspirated engine in the legacy fleet, a turbocharged engine in the legacy fleet, and a prototype turbocharged super lean-burn engine, to identify their effects on thermal efficiency and exhaust emissions. The lower carbon intensity fuel could provide almost equivalent engine power and thermal efficiency as conventional fuel, as well as satisfactory criteria emission results. It was also shown that a turbocharged super lean-burn engine combined with a lower-carbon intensity fuel consisting of 100% renewable components can reduce the well-to-wheel (WtW) CO2 value by more than 50%, and, when paired with a state-of-the-art hybrid vehicle, a greater than 70% reduction in WtW emissions can be achieved relative to an average vehicle on US roads today [2025-01-8442][2025-01-8439].

Emission Control Systems

The emission aftertreatment configurations that have been revealed by engine manufacturers for meeting the upcoming CARB/EPA 2027 low-NOx emission standards are based on a dual SCR system and/or electrical heater(s) to ensure adequate low-temperature performance. However, no papers on the 2027 emission systems have been presented by major engine or component suppliers. Among alternative engine concepts, Achates Power [2025-01-8391] confirmed earlier claims that their opposed piston 2-stroke (OP2S) engine can meet the 2027 emission standards and the 2027 GHG Phase 2 regulation using a conventional aftertreatment system.

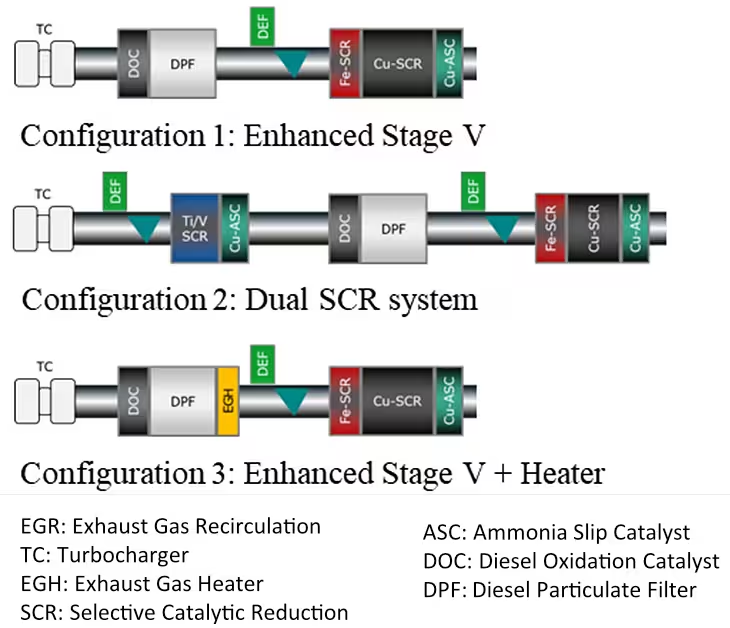

AECC evaluated three emission control system configurations for nonroad engines meeting future emission standards, beyond the EU Stage V regulation, Figure 2 [2025-01-8489]. A simulation study showed that while the single-dosing SCR system can address certain shortcomings of the Stage V regulation, the dual-dosing SCR and exhaust gas heater systems can provide further emission benefits, such as during alternating operating conditions, continuous low-load operation, and initial cold-start.

(Source: AECC)

Southwest Research Institute (SwRI) discussed the development of low-NOx aftertreatment system for meeting future CARB Tier 5 emission standards for nonroad engines (NOx = 0.040 g/kWh, NRTC/RMC) [C. Sharp - oral only]. The system configuration was similar to the system presented last year and to the dual SCR system in Figure 2. After aging to 8,000 hrs, the aftertreatment system met the applicable emission standards on all duty cycles with a significant margin, with no excessive N2O emissions. Heated urea doser and cylinder deactivation hardware, while part of the experimental setup, were not necessary for meeting the emission targets.

A study by Umicore [2025-01-8478] assessed two aftertreatment configurations—a dual SCR and a single SCR (SCRT), both utilizing an electric heater—for meeting China VII emission standards for heavy-duty engines. The anticipated CN VII NOx limits are 460/90 mg/kWh (cold/hot start WHTC) and the anticipated effective date is 2029. Several performance aspects were evaluated using a copper-based corrugated SCR (former Haldor Topsoe technology) and a conventional catalyst coated on a cordierite substrate.

Engines & Combustion

Honda reported on the development of a new naturally aspirated in-line 4-cylinder DI gasoline engine for C segment sedans [2025-01-8395]. The engine features an optimized shape of the combustion chamber to obtain rapid combustion and suppress knock, a large-capacity externally cooled EGR, and a two-piece water jacket that protects the exhaust system component by lowering the exhaust gas temperature at high load. The engine achieved the target output of 112 kW with a maximum thermal efficiency of 40% and PM emissions below 1 mg/mile.

Clemson, Lund, and Ghent Universities continued their work on the use of methanol fuel in compression ignition engines. Experiments were conducted on a methanol-fueled 2.1 L single cylinder engine equipped with a glow plug [2025-01-8412]. The engine was designed for alcohol combustion with an elevated compression ratio (26:1) and a narrow injector umbrella angle (120°) compared to standard diesel compression ignition hardware. It was found that the glow plug had no significant impact on conventional, mixing-controlled combustion strategy because no plume was not directly intercepted by the glow plug. In advanced, kinetically controlled combustion strategies, the glow plug advanced combustion phasing by several degrees, due to an apparent combination of charge heating and small amounts of exothermic reactions from fuel located near the glow plug during the compression stroke.

Tour Engine presented an overview of their split-cycle engine architecture and the performance of their current 5 kW engine prototype [6415]. The company also reported on the operation of the split-cycle engine on methane and various hydrogen/methane fuel blends [6416].

Several papers and presentations were devoted to hydrogen-fueled internal combustion engines in both light- and heavy-duty applications. Example papers include:

- An experimental and numerical study by Ferrari [2025-01-8424] evaluated hydrogen operation on a single cylinder engine retrofitted to H2 with direct injection. To reduce the risk of knock and pre-ignition, three different dilution techniques were tested: enleanment, cooled EGR, and manifold water injection (WI). Each of these dilution strategies requires a dedicated hardware optimization. Enleanment has an impact on the size of the turbocharger system, cooled EGR affects the engine heat rejection, while WI requires dedicated injection system and tank.

- A paper by Cummins [2025-01-8393] discussed the development of a 6.7 L H2 spark ignition engine for medium-duty commercial vehicles. The engine features a low-pressure DI fuel injection system, a tumble-based combustion system with a pent-roof combustion chamber, dual overhead cams (DOHC) with cam phasers, and no EGR. Test results showed that the engine produced above 40% BTE over a wide range of engine speed and load. Unlike the diesel and gasoline versions of the 6.7 L engine, the hydrogen version uses 2-stage boosting that produces λ > 2.0 across the full engine operating map, thereby leading to low engine-out NOx emissions.

- A team from the King Abdullah University of Science & Technology and Saudi Aramco [2025-01-8428] modified a heavy-duty Volvo D13 diesel engine to operate as a lean-burn, SI hydrogen engine with a high compression ratio of 17:1. The study found that hydrogen operation could significantly improve thermal efficiency. NOx emissions were found to be negligible under most operating conditions.

- Hydrogen fuel has also been tested in alternative combustion engines. A paper by Achates Power and Argonne [2025-01-8430] talked about the operation of the Achates OP2S engine on hydrogen, while a study by the Tongji University [6423] investigated the effect of lubricating oil consumption on the efficiency and performance of an H2 fueled argon power cycle engine.

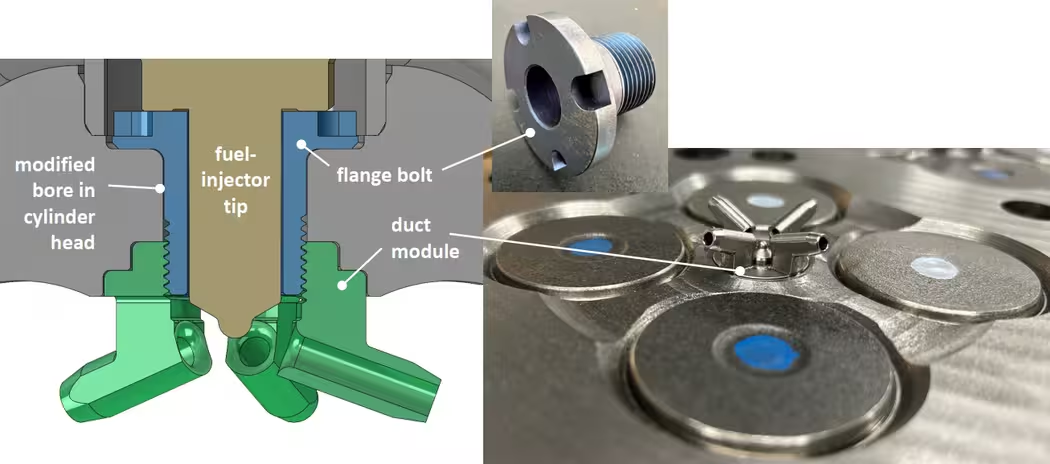

John Deere [R. Ogren - oral only] retrofitted a heavy-duty diesel engine with a ducted fuel injection (DFI) system. The project represents the first-ever DFI retrofit on a multi-cylinder production engine. The DFI technology, developed at Sandia National Laboratories, involves placing a duct downstream of the injector nozzle holes but upstream of where flame lift-off occurs. A DFI consortium (CRC Project AVFL-44) targets at least 70% engine-out soot reduction using production-viable DFI hardware. The retrofitted engine was 9.0 L, 6-cylinder John Deere 6090HF475 with a dual turbo, VGT, and high-pressure common rail fuel injection. Testing over the ISO 8178 cycle revealed an 87% reduction in soot emission, as well as a 42% reduction in NOx achieved through engine calibration. Deposits formed on ducts in one cylinder during the testing campaign were fixed by replacing the injector and using a detergent additive in the fuel.

(Source: John Deere)

Several engine combustion and spray modeling papers were also presented, dealing with studies of gasoline, diesel, and alternative fuel sprays, CFD models for spray processes, wall films and impingement, fuel injection equipment, and related topics.

* * *

The next SAE WCX Congress is scheduled for April 14-16, 2026 in Detroit, Michigan.