Conference report: 37th International Vienna Motor Symposium

12 May 2016

The Vienna Motor Symposium was held for the 37th time on April 28-29, 2016 in the Hofburg Conference Center in Vienna, Austria. As was the case in previous years, the main focus was on light-duty gasoline and diesel engine technology. Representatives of higher level management from several European car manufacturers discussed the challenges faced by the world’s automotive industry—driven largely by existing and future CO2 emission and fuel economy regulations—and their impacts on powertrain development. A number of technical papers were also presented dealing with such issues as new engine design, engine components, exhaust aftertreatment, and powertrain electrification. The conference was at its usual attendance level of about one thousand delegates.

Please log in to view the full version of this article (subscription required).

Automotive Industry Trends

The internal combustion engine will continue to be a critical component of the vehicle’s drivetrain for at least the next decade. Diesel engines, especially in Europe, are critical to allow manufacturers to meet CO2 targets and they continue to evolve with increased efficiency and reduced emissions. There is also an increased focus on ensuring emissions under real world driving conditions are reduced while meeting customer expectations for power and agility. Gasoline engine peak efficiencies continue to increase with some new commercial engines reaching 40%.

Drivetrain electrification efforts will only increase with hybrid and plug-in hybrid vehicles being the focus of development and marketing efforts. Dual voltage 12/48 V hybrids offer many of the benefits of full hybrid systems at a fraction of the cost to make them a more attractive alternative to conventional non-hybrid drivetrains. Hybrid vehicles will continue to see improvements in efficiency due to improvements in combustion engine efficiency and predictive control strategies. These predictive control strategies attempt to optimize not only drivetrain operation but cabin thermal management for a given driving route.

Battery electric vehicles will continue to see development efforts but are not expected to sold in high volumes anytime soon. The focus of development is on increasing driving range with some OEMs believing that there will not be a significant penetration until batteries that allow the vehicle range to reach 500 km between charges become available and until the recharging infrastructure is greatly expanded. Vehicle costs of course would need to be competitive with IC engine based powertrains.

Regulatory Developments

An update on the light-duty RDE procedure was provided by the Joint Research Centre of the European Commission [T.G. Vlachos] and TÜV NORD [H. Schmidt]. While the monitoring phase of the RDE procedure has started and conformity factors for NOx have been established, additional RDE packages are still expected. The 3rd RDE package that deals with cold starts, hybrids, particle number (PN) conformity factors and DPF regeneration is expected in Q3 2016 while the 4th package on RDE In-Service Conformity requirements is expected in Q4 2016. PN conformity factors being considered are an initial factor of 2.8 dropping later to 1.8. RDE emissions compliance is expected over a range of conditions including ambient temperatures from -7 to +35°C. However, cold start emissions during a period of up to the first 5 minutes will be excluded. The current procedure recommends comparing CO2 emissions during the RDE and WLTC tests—TÜV NORD would like to see this as a requirement. The JRC discussed 10 case studies using 3 vehicles and 8 routes to assess the practicality and effectiveness of RDE provisions with respect to operating conditions. Of 10 trips, 4 were considered invalid; one due to excessive stop time, one due to insufficient urban driving and 2 due to excessive or insufficient dynamicity.

It has been widely reported that the gap between certification values and real world fuel consumption (CO2) is widening. While the inclusion of CO2 in RDE is under discussion, PSA Peugeot Citroen has already taken steps to better inform customers of what to expect in real world driving. PSA is collaborating with NGO Transport & Environment to publish real world fuel consumption data for their cars. Transport and Environment defines and validates the protocol, PSA carries out the test and Bureau Veritas (BV) audits the results. The protocol is based on the EU’s RDE program. To date, 18 cars have been tested and there are plans to extend the program to cover criteria pollutants in 2017. Some results have already been published. European regulators have taken an interest in PSA’s program.

Powertrain Technology

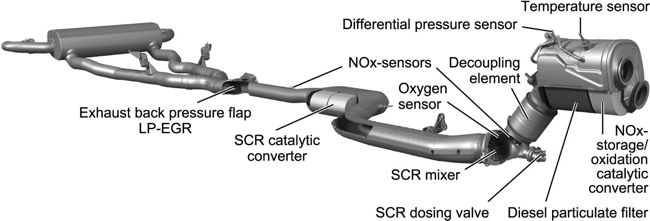

Diesel Engines. A number of presentations outlined new diesel engines for light-duty applications. Because of the timing of these engine introductions, manufacturers have had to ensure that these engines can be relatively easily made to comply with upcoming RDE requirements. While not all of these engines are necessarily RDE compliant, they are RDE ‘capable’ and should require only minor changes to ensure RDE compliance. To make these engines capable of meeting RDE requirements, some common changes include: close-coupled NOx aftertreatment and increased EGR rates at operating conditions outside the NEDC window. While urea SCR is the dominant NOx aftertreatment technology, in some cases this is combined with a NOx adsorber to increase NOx conversion when low exhaust temperatures are encountered. To expand the engine operating conditions over which EGR is used, some manufacturers are using dual high pressure/low pressure loop EGR systems.

One of the diesel engines presented was Daimler’s OM 654 [P. Lückert]. While many of the features of this engine were announced earlier this year, some additional details emerged. The stepped lip combustion system of this engine is much more compatible with EGR than the re-entrant bowl used in the previous OM 651 engine and allows considerably lower common rail injection pressures without increases in smoke emissions; at some part load conditions as much as 30% lower. Peak cylinder pressure has been reduced to 195 bar from 200 bar in the OM 651. While some versions the previous OM 651 used a dual loop EGR system for some lower power Euro 6 models that were able to certify without NOx aftertreatment, dual loop EGR is standard for the OM 654. Particular attention was paid to ensure EGR distribution among cylinders varied by no more than 3%; variations as high as 15% were common in the OM 651. The close-coupled aftertreatment system (DOC+sDPF+SCR) is also a critical component for meeting RDE requirements.

General Motors discussed a new 1.6 L Euro 6 diesel engine with a two-stage turbocharging system [G. Boretto]. GM introduced the 1.6 L diesel in 2013 (100 kW, 320 Nm) with a single turbocharger; the two-stage turbocharged version (118 kW, 350 Nm) was introduced in October 2015 in the Opel Astra and is intended to replace the 2.0 L engine in C-segment vehicles. The focus of the presentation was on the Honeywell charging system that consists of a variable geometry high pressure turbocharger and a wastegated low pressure turbocharger operated in a series sequential manner. While few details of the emission control system were presented, the current aftertreatment system consists of a close-coupled NOx adsorber and DPF. The 2.0 L that this engine will eventually replace uses urea SCR in applications such as the Opel Insignia.

Alfa Romeo presented a summary of their 2.2 L diesel engine for the new Alfa Romeo Giulia [E. Bonamassa]. This is the first all-aluminum engine for FCA and comes in two ratings; 132 kW/450 Nm and 155 kW/470 Nm. The cast iron block engine it replaces was rated at 147 kW and 440 Nm. The aluminum block is produced with a low-pressure die-cast process developed by FCA subsidiary Teksid and yields an engine 30 kg lighter than the cast iron version. The single Honeywell VNT turbocharger is integrated into an insulated exhaust manifold, has a ball bearing cartridge, water cooled center housing and for the 155 kW engine, comes with a turbocharger speed sensor to allow maximizing boost pressure while avoiding over-speeding during transients and high altitude. A dual loop EGR system ensures sufficient EGR flow at all operating conditions. The aftertreatment system consists of a NOx adsorber and DPF. For RDE, a urea SCR catalyst will be incorporated.

BMW unveiled a 6 cylinder 3.0 L diesel engine with 4 turbochargers and rated at 294 kW/760 Nm [F. Steinparzer]. The engine is the new generation version of the 3 turbocharger 3.0 L engine introduced in 2012. The boosting system is similar to that of the 2012 engine except that two low pressure turbochargers operated in parallel replace the single low pressure turbocharger. The two low pressure turbochargers have lower inertia than the single turbocharger and considerably improve transient performance. Emission control performance is improved as well with the addition of a dual loop EGR system. The aftertreatment system consists of a close-coupled oxidation catalyst/NOx adsorber followed by a DPF and an underfloor urea SCR catalyst.

Schaeffler, Ford and Continental discussed a 48 V hybrid concept car, GTC2. The drivetrain is based on a P2 hybrid (a 12 kW electric machine placed between the engine and transmission) with both engine side and transmission side clutches that allow the engine to be completely disengaged from the drivetrain [U. Wagner and O. Maiwald]. The turbocharged combustion engine is based on the 1.0 L Ecoboost with late intake valve closing. A belt driven A/C compressor is attached to the hybrid module, allowing the A/C function to be maintained even with the engine off. This combination allows a number of features such as electric creeping, hybrid driving, coasting and sailing and recuperation that add up to fuel/CO2 savings of 30% over the NEDC and 11% over the WLTP.