Conference report: SAE WCX 2022 Congress

27 April 2022

The SAE 2022 WCX World Congress Experience was held on April 5-7, 2022 in Detroit as an in-person event—for the first time in three years. Remote access was also provided, with some sessions available via live streaming, and others via on-demand recordings. The Congress was attended by 3717 participants, including 2763 in person and 954 digital. The three day schedule included 800 technical papers and a number of keynote speeches, discussion panels, and oral-only presentations covering all areas of automotive technology. The following summary details a number of noteworthy WCX 2022 talks on engines and engine emission topics.

Please log in to view the full version of this article (subscription required).

Emission Policy & Regulations

Ameya Joshi of Corning presented a technical keynote on recent developments in vehicle efficiency and emissions. The talk covered new emission regulations—such as the California low NOx rule and Euro 7—and the technologies that are being developed to meet these future requirements, including new and improved engine concepts (SuperTruck 2 and opposed piston engines), exhaust gas thermal management, and enhanced aftertreatment systems. Ambitious decarbonization targets are also being adopted that demand—at the policy level—zero tailpipe emissions and high levels of vehicle electrification. On the other hand, life cycle analysis (LCA) shows that emission effects of electric vehicles depend on the application, electricity grid mix, and other factors—in many cases electrification can increase GHG emissions.

The decarbonization targets adopted or considered in the United States and Europe would depend on massive investment in renewable electricity and minerals extraction and refining—a fact that seems underappreciated by many policy makers. One example regulation with ambitious electrification targets is the Advanced Clean Cars II (ACC II) package currently under development by CARB. Under the proposed requirements, 100% new sales of light-duty vehicles in the state would have to be ZEV and PHEV vehicles by 2035, increasing at 8% per year from 2026 through 2031, and 6% thereafter. Assuming the ACC 2 requirements are adopted in California as well as in the 14 ‘section 177’ states, the annual electric battery requirement in the US market would be ~430 GWh by 2030, and ~800 GWh by 2035. To put this in perspective, the total Li-ion battery manufacturing capacity in the USA was ~44 GWh in 2021. Hence, to meet the ACC 2 demands, US battery production capacity would have to increase 10× by the end of the decade and another 2× in the following 5 years.

Numerous studies have suggested that battery electric vehicles would provide the quickest path to reduce GHG emissions from light-duty vehicles, while tacitly assuming unlimited availability of resources from which to produce batteries for these vehicles. This, coupled with range anxiety of many BEV buyers, leads to BEVs with large batteries that do not make effective use of available battery resources. In a more realistic battery resources constrained scenario, it makes more sense to equip as many vehicles as possible with relatively small batteries that meet most drivers daily driving needs rather than to have the same resources tied up in a smaller number of BEVs with oversized batteries. Roland Dauphin from CONCAWE argued that focusing on increasing the uptake of PHEVs in Europe rather than BEVs could achieve this objective. Even with conservative utility factors in the range of 23% to 39%, PHEVs recharged every 1-2 days are preferable to HEV and BEVs in reducing GHG emissions whatever their battery capacity is (20-100 km AER) out to 2030 with currently estimated battery capacity availability. Even if PHEV occurs every 5 days, lower range PHEVs (20-30 km AER) would still be preferable over HEVs and BEVs in reducing GHGs under the assumed battery supply constraints. Only when annual battery supply capacity in Europe exceeds 0.55 TWh/y would selling dominantly BEVs provide the lower WTW GHG emissions. Their estimation assumes that PHEV fuel consumption in charge sustaining mode is lower than for an ICEV [5471].

Paul Miles, Sandia National Laboratories, pointed out that the 2021 EIA International Energy Outlook predicts that by 2050, ground transportation will still be dominated by combustion engines. However, currently available technologies could provide ~50% fuel consumption reduction in the light-duty fleet. Some of the engine innovations that could be explored further for efficiency gains include split-cycle engines, opposed piston engines, hydrogen engines, advanced compression ignition strategies, lean SI combustion, advanced GDI injection (up to 1000 bar, high precision laser drilled holes, nozzle geometry), variable compression ratio, valve train technologies such as continuously variable valve duration and dynamic cylinder deactivation as well as advanced diesel engine technologies that enhance late cycle mixing to reduce soot oxidation to enable further improvements in efficiency and reductions in NOx (e.g., WAVE piston, ducted fuel injection).

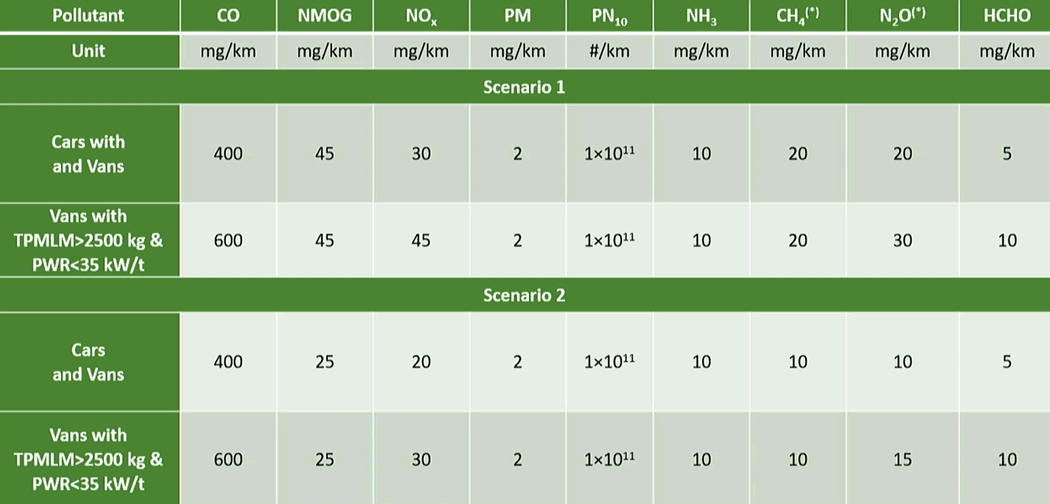

The official EU Euro 7/VII proposal, delayed on several occasions, is now expected in July 2022 [Zissis Samaras, Aristotle University/CLOVE]. The Euro 7/VII regulation will tighten existing emission standards, introduce emission limits for new, previously unregulated emissions, and introduce significant changes to emission testing procedures, including the Real Driving Emissions (RDE) testing. A possible set of Euro 7 emission limits, based on the work of the EU CLOVE Consortium, is shown in Figure 1. The list of emission species that may become regulated pollutants includes NO2, NH3, N2O, NMOG, CH4, ethanol, HCHO, acetaldehyde, and particle numbers down to 10 nm (SPN10).

(CLOVE Consortium)

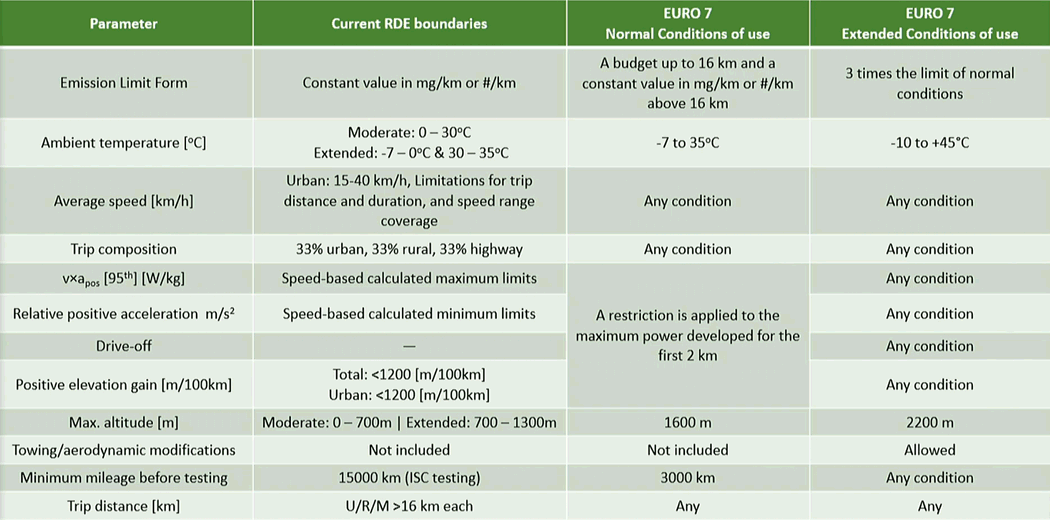

The considered changes to RDE emission testing would relax or remove entirely several of the RDE boundaries and trip requirements. These changes will expand the set of driving conditions within a valid RDE trip, making the test more challenging to pass.

(CLOVE Consortium)

Engine Technology

Diesel Engines. Achates updated progress on their CARB funded demonstration project developing a 10.6 L opposed piston diesel engine meeting CARB 2027 emission limits for a Class 8 tractor. As reported previously, the aftertreatment system now incorporates a DPF followed by two SCR bricks rather than the SCRF followed by a single SCR brick used earlier. This updated system improves passive regeneration and allows the use of an off-the-shelf MY 2021 aftertreatment system. The ability to use current aftertreatment systems combined with an estimated 7% lower base engine cost suggests that the opposed piston engine will be a very competitive option for meeting upcoming ultra-low NOx limits. In addition to completing on-road testing, future work includes full cold start testing and 800,000 mile aging. Hydrogen work is also planned for the engine [5472].

SwRI evaluated the efficiency benefit of increasing compression ratio from 17:1 to 22:1 in a diesel engine equipped with a Volvo WAVE piston. One challenge with higher compression ratios in diesel engines is the more confined piston bowl that can significantly affect in-cylinder mixing. Using CFD simulation work to optimize the bowl design, a 1% improvement in indicated efficiency in a single cylinder engine was achieved that was later confirmed with multi-cylinder testing. Associated with the increased efficiency was an increase in peak cylinder pressure from 193 bar to 246 bar [5473].

Natural Gas Engines. Reducing unburned methane emissions from dual fuel natural gas engines was addressed in several papers. Research at the University of Kaiserslautern studied the effect of internal and cooled external EGR in a John Deere 4045 engine modified for dual fuel operation with natural gas injected via multiple port injectors. At a medium load operating condition (1600 rpm/9.8 bar BMEP and 75% methane energy ratio), internal EGR via a second exhaust valve lift during the intake stroke increased residual gas fraction from 7% to 18% and reduced CH4 emissions from ~9 g/kWh to ~5.3 g/kWh (-41%). Adding 20% cooled external EGR on top of this further increased the residual gas fraction to 31% and further reduced CH4 to ~3.8 g/kWh (-29%) [5480].

An alternative approach to reducing methane emissions was studied by researchers at Canada’s NCR who looked at the effect of an insert in the intake manifold that would alter the intake flow profile into the engine in a way that would intensify the mixing between diesel and the air/natural gas mixture. Testing at a medium engine load and low engine speed showed that the use of the intake insert decreased methane slip by ~28% and carbon monoxide emissions by ~25% at the expense of an increase in the emissions of NOx by ~23% and a decrease in the indicated thermal efficiency by ~1.7%. Low levels of EGR reduced the NOx emissions in dual fuel mode without a significant impact on the GHG or PM emissions when compared to diesel combustion [5474].

Work carried out at Michigan Technological University demonstrated that a multi-cylinder Cummins ISB 6.7L diesel engine converted to operate at a stoichiometric air/fuel ratio using premixed natural gas and ignited by a diesel micro-pilot was able to achieve 40% BTE at 1600 rpm and 10 bar BMEP. The compression ratio was reduced to 15:1 and diesel injection quantity was 3.3 mg/injection which allows the diesel contribution to remain below 10% [5475].

Emission Control

A number of papers were devoted to technologies for meeting future low NOx emission regulations, including the California ‘Omnibus’ regulation, the proposed US EPA low NOx rule, as well as Euro 7/VII. SwRI [Chris Sharp] provided an update on the ongoing low NOx engine demonstration program, using aftertreatment system aged to 800,000 miles—the final durability target of the California low NOx regulation. A 2017 Cummins X15 engine equipped with cylinder deactivation (CDA) hardware by Eaton was used in the most recent stages of the demonstration. Fitted with a dual SCR catalyst and dual urea dosing aftertreatment system, it is referred to as the ‘CARB Stage 3 RW’ configuration.

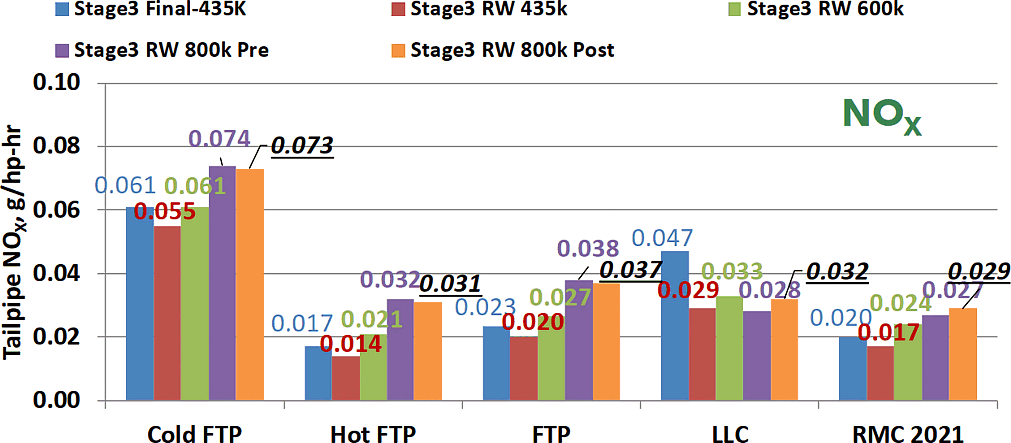

NOx emission performance of the various stages of the system is compared in Figure 3. While NOx emissions were below the 800,000 mile limits (0.04 g/bhp-hr for FTP & RMC, 0.10 g/bhp-hr for LLC), the FTP standard was met with a very slim margin of only 2% (when IRAF, not shown in the figure, is also considered). Other performance aspects that could benefit from improvement include N2O emissions and in-use emission results.

Results do not include Infrequent Regeneration Adjustment Factor (IRAF = +0.002 FTP/RMC, +0.005 LLC)

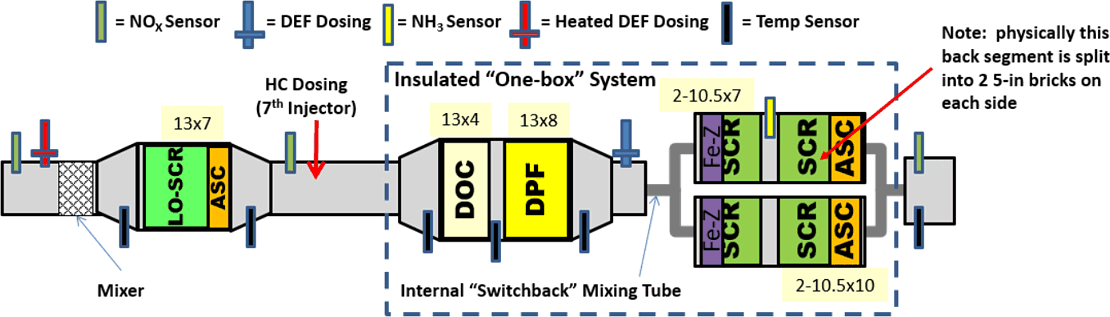

The next stage of the program will use the ‘EPA System A’ configuration, Figure 4. The main changes from the CARB Stage 3 RW system include an increased volume of the light-off SCR (LO-SCR) catalyst to improve NOx performance, and a new, hybrid, Fe-Z / Cu-Z SCR formulation of the main SCR catalyst to mitigate the N2O concerns.

Upcoming ultra-low NOx standards require careful attention to aftertreatment thermal management to ensure that catalysts not only heat up quickly but also stay hot during engine idle periods. While technologies such as cylinder deactivation, insulation and EGR cooler bypass can help, these typically do not provide enough benefit in the first 200 s of a cold start to rapidly light-off a conventional aftertreatment system with the SCR catalyst placed after the DPF. SuperTurbo presented data [5460] showing that their mechanically driven turbocharger coupled with a turbine bypass and engine start/stop is an option that can accelerate exhaust temperature rise after a cold start and minimize catalyst temperature drops during engine idle periods while using a typical EPA 2010 aftertreatment system. Relative to the baseline calibration on a 2017 Cummins X15 engine, DOC inlet temperatures about 100°C higher in the first 100 s of the FTP cold start cycle were noted and SCR conversion rates at 320s under winter conditions could rise to over 80% while reducing fuel consumption during the cold start period. While similar temperature and NOx conversion improvements were noted over the cold start WHTC cycle, start/stop had less impact on this cycle because of the lower proportion of idle.

FEV developed a simulation model to investigate the possibility of simultaneous reductions of NOx and CO2 emissions through the application of 48V electrification for engine and aftertreatment system [5462]. Compared to the high voltage systems, 48V electrification can offer a relatively lower cost solution to meet future regulations. Additional benefits include lower integration efforts, reduced safety concerns, and a lower weight package. The baseline engine model was calibrated against test data from a 2017 6-cylinder 7.7 L US EPA Phase 1 GHG complaint diesel engine with a 228 kW power rating. The baseline engine was integrated with a 48V technology package for fuel consumption reduction and aftertreatment thermal management. The engine technology package included electrification of the air handling system using a 48V E-Turbo and a 48V EGR pump, friction reduction with downspeeding, and CDA for thermal management. Another model was developed to define an advanced aftertreatment system that included a 48V electrically heated catalyst in combination with a fuel doser and a low temperature SCR catalyst to reduce cold start emissions. The advanced engine and aftertreatment system were then coupled for complete system simulations. The results showed that the proposed 48V technology package could achieve 0.02 g/bhp-hr NOx emission levels while simultaneously meeting the 2027 Phase 2 GHG emission standards.

Two studies examined the use of a fuel burner (Tenneco) to enhance SCR performance. In one study [5463], the burner was used with a conventional SCR aftertreatment system. Tailpipe NOx emissions were shown to be significantly reduced with the burner over the test cycles used in the study. Over the LLC cycle, NOx emissions could be reduced to as low as 0.05 g/hp-hr. However, burner operation also resulted in a CO2 increase, indicating that a different burner calibration strategy, or possibly an additional technology would be needed to achieve lower CO2 emissions. Another study [5464] proposed to use a fuel burner to pre-heat the SCR catalyst before the engine is started, so that it could begin to convert NOx almost immediately after a cold start. The burner was installed on a 12.4 liter engine with a DOC/DPF/SCR aftertreatment, the optimum fueling and combustion air flow rates for the burner were determined, and the system was evaluated over the cold- and hot-start FTP and WHTC. The SCR pre-heating strategy is considered particularly suitable for Euro VII engines that do not use EGR and have therefore relatively high engine-out NOx emissions.

Electrically heated catalysts (EHC) are another thermal management technology considered for future light- and heavy-duty emission standards. While commercial EHC designs are typically based on metallic substrates, NGK and Toyota reported on the development of a ceramic EHC [5461]. The challenges in using ceramics include controllability of the current distribution, durability, and reliability of the connection between the substrate and the electrodes. The ceramic EHC substrate was made of cordierite with the addition of conductive Si-SiC material. Structural modifications were made to improve the thermal shock resistance, which was identified as a potential problem due to the difference in the coefficient of thermal expansion between cordierite and Si-SiC.

FPT Industrial discussed an accelerated aging methodology for Stage V / Tier 4 emission aftertreatment system comprised of a DOC placed directly after the engine, followed by a particulate filter with an SCR active coating (SCRF) and an SCR-coated substrate combined with an NH3 oxidation catalyst [5470]. The aging steps in the proposed procedure included low and high temperature exposure, sulfur poisoning, HC poisoning and exothermic HC burn-off, inducement of urea deposits formation, soot and ash loading. As a result of the engine test bench aging, a full-useful-life (8,000 hrs) aftertreatment system was obtained and successfully compared to a vehicle-aged system.

Johnson Matthey [5469] developed a new three-way catalyst (TWC) coating for China 6 gasoline particulate filters (GPF) where palladium was replaced with a lower cost platinum (as of 4/26: Pt = $925/t.o., Pd = $2,117/t.o., Rh = $16,650/t.o.). The new Pt/Rh GPF was evaluated for back pressure, PN filtration efficiency and TWC activity, and compared favorably with the commercial Pd/Rh GPF. The new Pt/Rh GPF passed technical verification by some customers in China and was applied on China 6 platforms in both the underfloor and the close-coupled locations.

In the anticipation of a new Euro 7 emission limit for ammonia, Tula Technology [5468] proposed a new ammonia emission control strategy in gasoline engines, using deceleration cylinder cut-off (DCCO) to reduce or eliminate conventional deceleration fuel cutoff (DFCO) and the associated lean-rich excursions in the three-way catalyst during oxygen saturation and desaturation. The improved air-fuel ratio management closer to stoichiometry lowers the ratio of CO to NOx and thus the ammonia formation rate over the TWC. Tests showed more than 80% reduction of ammonia emissions over the WLTC cycle without increasing other regulated emissions.