USA: Heavy-Duty Onroad Engines: MAW Off-Cycle Emission Testing

Overview

California’s 2024 and later and EPA’s 2027 and later emission standards for onroad heavy-duty diesel engines include an in-use testing requirements with PEMS that is intended to replace the chassis based NTE testing procedure used previously. While CARB and EPA worked together on developing the test procedure, the final regulatory documents released by the two agencies reveal some substantial differences [5726][5724]. Testing using the MAW procedure is required for CARB certified engines starting with MY 2024 and for EPA certified engines starting with MY 2027.

Please log in to view the full version of this article | Subscription required.

Both jurisdictions use a moving average window method that has similarities to the Euro VI OCE/ISC procedure. While the Euro VI procedure uses work or CO2 based windows, the US procedures use time-based windows. Engine operation and emissions test data are assessed in test intervals that consist of 300 s moving average windows (MAWs) of continuous engine operation using data collected at 1 Hz. Windows will overlap each other with a time increment equal to the 1 s data collection rate. The windows are sorted into bins depending on the relative engine power and overall emissions for each bin are then evaluated and compared to an applicable emission standard. A compliance margin is applied to account for measurement uncertainty. Table 1 summarizes some important requirements for the tests.

| CARB | EPA | |

|---|---|---|

| Applicability | MY 2024 and later | MY 2027 and later |

| Bins | 3 | 2 |

| Length | 1 shift-day | 1 shift-day |

| Start of test | Cold start, engine coolant < 30°C | Engine coolant < 40°C |

| Min. windows/bin* | 2,400 | 2,400 in bin 1 10,000 in bin 2 |

| Average engine power over the test | For 2024 through 2026 MY, ≥ 10% of peak power | - |

| * testing into a second shift-day or idling at the end of a shift-day is allowed to achieve a sufficient number of windows | ||

Bins

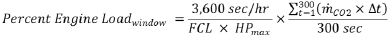

Bin boundaries are determined using percent engine load. The percent engine load is determined using the nominal “normalized average CO2 rate” from the certification test cycles. For each window, the percent engine load for that window is calculated by dividing average CO2 emission rate [g CO2/hour] during the 300 s window by the product of the engine’s FTP CO2 family certification level (FCL) value [g/bhp-hr] and the maximum power output of the engine [hp], Equation (1).

(1)

(1)

Table 3 summarizes the nomenclature and definition of bins for CARB and EPA. EPA bin 2 covers the range of engine loads included in CARB low and medium/high bins.

| Percent Engine Load | CARB Bins | EPA Bins |

|---|---|---|

| Percent Engine Loadwindow ≤ 6% | Idle | 1 |

| 6% < Percent Engine Loadwindow ≤20% | Low | 2 |

| 20% < Percent Engine Loadwindow | Medium/High |

Emissions Evaluation and Pass Criteria

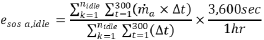

Unlike the Euro VI MAW method in which the 90th percentile emissions are compared with an emissions threshold to determine compliance, the US method uses a sum-over-sum approach. The sum-over-sum approach accounts for emissions in all the windows at both the highest and lowest emission rates compared to the percentile method that focuses on a single value at the 90th percentile. The sum-over-sum emissions within each of the bins would need to be at or less than their threshold values for compliance. The sum-over-sum (SOS) window emissions [g/hr] for the CARB idle bin and EPA bin 1 is calculated with Equation (2):

(2)

(2)

where ma is the mass emission rate [g/sec] of the pollutant. At idle, only NOx emissions are limited.

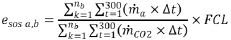

For CARB low and medium/high bins and EPA bin 2, the sum-over-sum emissions [g/bhp-hr] are determined with Equation (3):

(3)

(3)

Table 4 summarizes the compliance criteria for CARB and EPA bins. The EPA SOS NOx limit for bin 1 reflects a conformity factor of 1.0 times the Clean Idle standard. The EPA bin 2 standards for all pollutants reflect a conformity factor of 1.5 times the standards for the LLC and SET cycles. The combined NOx and HC bin 2 standard is weighted at 25% of the LLC standard and 75% of the SET standard. Additionally, an interim NOx compliance allowance applies for Medium and Heavy HDE that adds an additional 15 mg/hp-hr NOx allowance above the bin 2 standard of 58 mg/bhp-hr. The interim NOx compliance allowance may be reviewed in the future.

| CARB | EPA | ||

|---|---|---|---|

| Bin | CARB SOS limit | Bin | EPA SOS limit |

| Idle | esos a,Idle ≤ CFa × Idle standard | 1 | NOx: 10 g/hr |

| Low | esos a,Low ≤ CFa × LLC standard | 2 | NOx: 58/73b,c mg/bhp-hr HC: 120 mg/bhp-hr PM: 7.5 mg/bhp-hr CO: 9 g/bhp-hr |

| Medium/High | esos a,MedHigh ≤ CFa × FTP/RMC standard | ||

|

a For 2024 through 2029 model year engines, the conformity factor, CF, is equal to 2.0. For 2030 and subsequent model year engines, the conformity factor, CF, is equal to 1.5. b An interim NOx compliance allowance of 15 mg/hp-hr applies for any in-use testing of Medium HDE and Heavy HDE. Manufacturers will add the compliance allowance to the NOx standard (58 mg/bhp-hr) that applies for each duty cycle and for off-cycle bin 2, for both in-use field testing and laboratory testing. c Limit at 25 °C. At 5 °C, a 117 mg applies to Medium HDE and Heavy HDE. At temperatures between 5 and 25°C, the limit is determined by linear extrapolation. | |||